描述

一、核心功能与技术参数

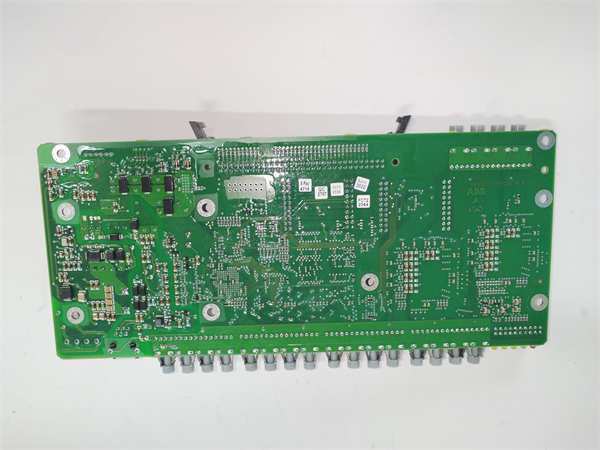

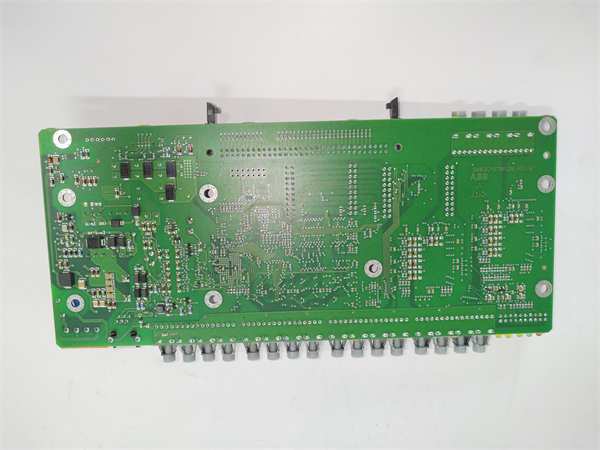

1.基本信息

品牌:ABB

系列:Bailey(贝利)系列

类型:操作单元自动控制器或逻辑站终端单元

定位:工业自动化系统的核心控制模块,适用于高精度控制、数据采集与处理。

2.功能特性

控制能力:

高精度控制:支持位置、速度的高精度控制,适用于机器人、数控机床等场景。

多协议兼容:内置以太网/IP、Modbus等通信协议,支持与PLC、DCS系统集成。

冗余设计:可实现一对一冗余,提升系统可靠性。

数据处理:

实时监测:采集温度、压力、流量等模拟量信号,支持数据存储与分析。

逻辑编程:通过编程实现自定义控制逻辑,适配不同工业场景需求。

扩展性:

支持Harmony Block和Rack I/O系统,兼容ABB S800、S900系列模块。

3.技术规格

物理参数:

尺寸:20×20 cm(参考体积)

重量:1 kg

防护等级:IP20(标准)或IP65(可选)

环境适应性:

工作温度:-20°C至+70°C

存储温度:-40°C至+85°C

通信接口:

网络接口:以太网/IP、Modbus TCP/IP

本地接口:数字量I/O、模拟量I/O

二、应用场景

工业自动化:

机器人运动控制、数控机床的伺服驱动、生产线设备协同。

电力与能源:

电力厂的电能质量监测、水处理厂的实时运行管理。

过程控制:

化工、冶金行业的温度、压力调节与安全联锁。

智能设备:

智能车辆的障碍物检测、智能家居的环境控制。

NTAC-02 58967441E

NTAC-02 58967441E

1.Core functions and technical parameters

1.Basic information

Brand:ABB

Series:Bailey Series

Type:Operating unit automatic controller or logical station terminal unit

Positioning:The core control module of industrial automation system,suitable for high-precision control,data acquisition and processing.

2.Functional characteristics

Control ability:

High-precision control:supports high-precision control of position and speed,suitable for robots,CNC machine tools and other scenarios.

Multi-protocol compatible:built-in Ethernet/IP,Modbus and other communication protocols,supports integration with PLC and DCS systems.

Redundant design:One-to-one redundancy can be achieved and system reliability can be improved.

Data processing:

Real-time monitoring:collects analog signals such as temperature,pressure,and flow,and supports data storage and analysis.

Logic programming:Custom control logic is implemented through programming to adapt to the needs of different industrial scenarios.

Scalability:

Supports Harmony Block and Rack I/O systems,and is compatible with ABB S800 and S900 series modules.

3.Technical specifications

Physical parameters:

Dimensions:20×20 cm(reference volume)

Weight:1 kg

Protection level:IP20(standard)or IP65(optional)

Environmental adaptability:

Operating temperature:-20°C to+70°C

Storage temperature:-40°C to+85°C

Communication interface:

Network interface:Ethernet/IP,Modbus TCP/IP

Local interface:digital I/O,analog I/O

2.Application scenarios

Industrial automation:

Robot motion control,servo drive of CNC machine tools,and production line equipment coordination.

Electricity and Energy:

Power quality monitoring of power plants and real-time operation and management of water treatment plants.

Process control:

Temperature,pressure regulation and safety interlocking in the chemical and metallurgy industries.

Smart devices:

Obstacle detection of smart vehicles and environmental control of smart homes.