描述

产品概述

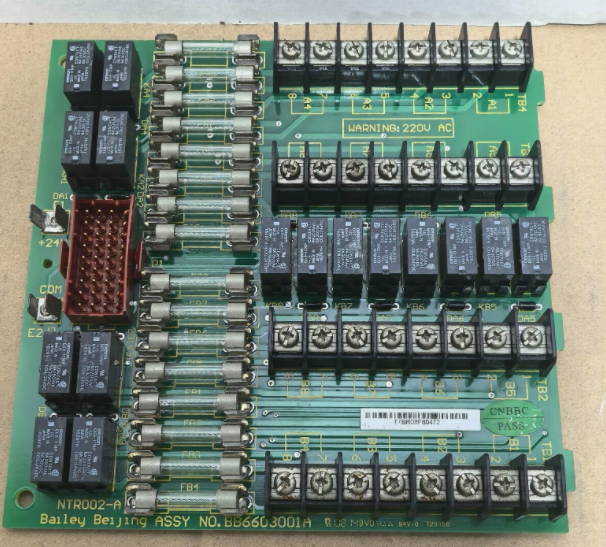

ABB NTR002-A是一款专为工业自动化应用设计的端子控制模块,以高效控制、高可靠性和灵活扩展性为核心特点。其适用于需要精准控制的场景,如生产线设备、机械臂运动控制、能源管理等,支持多协议通信和定制化编程。

核心功能与技术特点

1.高效控制能力

精准控制:采用先进控制技术,支持高精度位置控制和速度控制,满足复杂工业场景对动态响应的要求。

多模式操作:兼容脉冲/方向输入、模拟信号(如±10V)等控制方式,适配不同设备接口需求。

2.可靠性与稳定性

工业级设计:采用高品质材料和严格制造工艺,通过高温、高湿、电磁干扰等环境测试,确保长期稳定运行。

冗余保护:内置过流、过压保护机制,支持故障诊断与报警功能,提升系统安全性。

3.灵活输入输出配置

多协议兼容:支持Profibus、Modbus、EtherCAT等工业通信协议,便于集成至主流控制系统(如PLC、SCADA)。

可编程逻辑:通过编程实现自定义控制算法,满足个性化需求,例如逻辑门控制、定时任务调度等。

4.热管理与维护

散热优化:采用高效散热设计,可在-25°C至+70°C温度范围内稳定工作,避免过热导致性能下降。

模块化结构:支持热插拔维护,简化故障排查与组件更换流程,降低停机时间。

典型应用场景

工业生产线:

控制输送带速度、机械臂运动轨迹,提升生产效率与精度。

能源设备:

监测和调节发电机组、压缩机等设备的运行参数。

楼宇自动化:

管理空调系统、照明设备的智能启停与能耗优化。

测试与实验设备:

精确控制实验台的温度、压力等环境参数。

Product Overview

ABB NTR002-A is a terminal control module designed for industrial automation applications,with high efficiency control,high reliability and flexible scalability as its core features.It is suitable for scenarios that require precise control,such as production line equipment,robotic arm motion control,energy management,etc.,and supports multi-protocol communication and customized programming.

Core functions and technical features

1.Efficient control capability

Precise control:Adopt advanced control technology,supports high-precision position control and speed control,and meets the requirements for dynamic response in complex industrial scenarios.

Multi-mode operation:compatible with pulse/direction input,analog signal(such as±10V),etc.,and adapt to the interface requirements of different equipment.

2.Reliability and stability

Industrial-grade design:adopts high-quality materials and strict manufacturing processes,and ensures long-term and stable operation through environmental testing such as high temperature,high humidity,electromagnetic interference,etc.

Redundant protection:Built-in overcurrent and overvoltage protection mechanisms,supports fault diagnosis and alarm functions,and improves system security.

3.Flexible input and output configuration

Multi-protocol compatibility:supports industrial communication protocols such as Profibus,Modbus,EtherCAT,etc.,which is convenient for integration into mainstream control systems(such as PLC,SCADA).

Programmable logic:implements customized control algorithms through programming to meet personalized needs,such as logic gate control,timing task scheduling,etc.

4.Thermal management and maintenance

Thermal Optimization:Adopts an efficient heat dissipation design,which can operate stably in the temperature range of-25°C to+70°C,avoiding performance degradation due to overheating.

Modular structure:supports hot-swap maintenance,simplifies troubleshooting and component replacement processes,and reduces downtime.

Typical application scenarios

Industrial production line:

Control the speed of the conveyor belt and the movement trajectory of the robotic arm to improve production efficiency and accuracy.

Energy Equipment:

Monitor and adjust the operating parameters of generator sets,compressors and other equipment.

Building automation:

Manage intelligent start-stop and energy consumption optimization of air-conditioning systems and lighting equipment.

Test and experimental equipment:

Accurately control the temperature,pressure and other environmental parameters of the laboratory bench.