描述

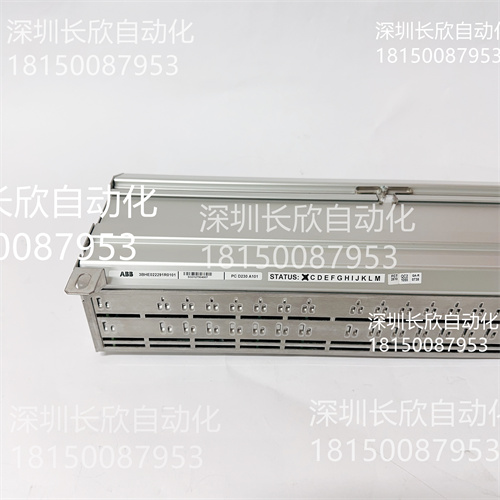

ABB PCD230A101 3BHE022291R0101是一款高性能励磁单元控制器模块,主要用于交流发电机励磁系统以及各种工业自动化和控制应用。它是电力系统中的关键组件,专门用于管理和稳定发电机的电压和无功功率输出。

主要特性和功能

励磁控制:其主要目的是向发电机转子绕组提供和控制磁场电流(励磁电流)。这对于将发电机的输出电压保持在规定范围内并控制其无功功率至关重要。

模块化数字励磁机组件:它是一款高性能、稳定的模块化数字励磁机控制器组件。

双数字控制器:该单元通常由两个独立的数字控制器组成,每个控制器都配有独立的微处理器、电源和数字输入/输出。这种冗余设计提高了可靠性,即使一个组件出现硬件故障也能确保持续控制。

整流和退磁:它包括整流功能(将交流励磁电流转换为直流励磁电流,通常通过三相全控桥式晶闸管整流电路)和退磁功能。

监控功能:它可以监控励磁电流,通常通过10V直流输出,以确保电气状态和设备正常运行。

可编程:支持高速虚拟PLC操作,可使用标准IEC-61131-3语言进行编程,为各种控制算法和任务提供灵活性。

高精度:具有高精度测量和控制能力。

内置诊断功能:包含诊断功能,方便维护和故障识别。

通信:配备强大的人机交互和通信功能。它支持Profibus DP、Modbus RTU/TCP和以太网等多种协议,可与其他电力系统设备无缝集成并进行远程控制。

内存和处理器:通常配备双核32位CPU,提供强大的计算能力和大容量DDR内存(例如128-256MB或512MB RAM,4GB闪存)。

I/O容量:单个控制器可配置大量I/O点(例如,最多2,048个),满足各种发电机励磁系统需求。

坚固耐用的设计:通常具有宽输入电压范围(例如,DC 9-36V),并配备冗余电源输入、电压隔离(例如,DC1500V)和反接保护功能。它可能采用波纹铝制加固外壳,防护等级达到IP30。

紧凑尺寸:物理尺寸通常紧凑(例如,宽100mm、高150mm、深50mm或210mm×150mm×80mm)。

应用

ABB PCD230A101广泛应用于发电和各种工业自动化领域,包括:

发电厂:用于蒸汽轮机发电机组和水轮发电机组的励磁控制,以确保稳定的电压和频率输出,从而提高电网的稳定性和可靠性。

工业自动化:用于各种需要精确电机或发电机励磁控制的机器人和通用自动化应用。

过程控制系统:可集成到更大型的过程控制和制造自动化系统中。

技术规格(典型值)

处理器:双核32位CPU

内存:通常为512 MB RAM,4 GB闪存(可能有所不同)

电源:24 VDC(通常带有冗余输入)

工作温度:-20°C至+60°C(或-25°C至+60°C)

尺寸:约100mm x 150mm x 50mm,最大可达210mm x 150mm x 80mm

重量:约0.5 kg至1.5 kg

The ABB PCD230A101 3BHE022291R0101 is a high-performance excitation unit controller module used primarily in AC generator excitation systems and various industrial automation and control applications.It’s a key component within the power system,specifically designed to manage and stabilize the voltage and reactive power output of generators.

Key Features and Functions

Excitation Control:Its main purpose is to provide and control the magnetic field current(excitation current)to the generator’s rotor winding.This is crucial for maintaining the generator’s output voltage within specified limits and controlling its reactive power.

Modular Digital Exciter Component:It’s designed as a high-performance,stable controller component for modular digital exciters.

Dual Digital Controllers:The unit typically consists of two independent digital controllers,each with its own microprocessor,power supply,and digital input/output.This redundant design enhances reliability,ensuring continuous control even if one component experiences a hardware failure.

Rectifier and Demagnetization:It includes functions for rectification(converting AC to DC excitation current,often via a three-phase fully controlled bridge thyristor rectifier circuit)and demagnetization.

Monitoring Function:It can monitor the excitation current,often through a 10V DC output,to ensure proper electrical conditions and equipment operation.

Programmable:Supports high-speed virtual PLC operation and can be programmed using standard IEC-61131-3 languages,offering flexibility for various control algorithms and tasks.

High Precision:Features high-precision measurement and control capabilities.

Built-in Diagnostics:Includes diagnostic functions for easier maintenance and fault identification.

Communication:Equipped with robust human-machine interaction and communication functions.It supports multiple protocols like Profibus DP,Modbus RTU/TCP,and Ethernet,allowing seamless integration with other power system devices and remote control.

Memory and Processor:Often features a dual-core 32-bit CPU for strong computing power and high-capacity DDR memory(e.g.,128-256MB or 512MB RAM,4GB flash memory).

I/O Capacity:A single controller can be configured with a significant number of I/O points(e.g.,up to 2,048),meeting diverse generator excitation system needs.

Robust Design:Typically has a wide input voltage range(e.g.,DC 9-36V)with redundant power inputs,voltage isolation(e.g.,DC1500V),and reverse connection protection.It may have a wavy aluminum reinforced case with an IP30 protection grade.

Compact Size:Physical dimensions are generally compact(e.g.,100mm wide,150mm high,50mm deep,or 210mm×150mm×80mm).

Applications

The ABB PCD230A101 is widely used in power generation and various industrial automation contexts,including:

Power Plants:Essential for excitation control of generators in steam turbine-generator units and hydro-generator units to ensure stable voltage and frequency output,thus improving power grid stability and reliability.

Industrial Automation:Used in various robot and general automation applications where precise motor or generator excitation control is required.

Process Control Systems:Can be integrated into larger process control and manufacturing automation systems.

Technical Specifications(Typical)

Processor:Dual-core 32-bit CPU

Memory:Typically 512 MB RAM,4 GB flash memory(may vary)

Power Supply:24 VDC(often with redundant inputs)

Operating Temperature:-20°C to+60°C(or-25°C to+60°C)

Dimensions:Approximately 100mm x 150mm x 50mm up to 210mm x 150mm x 80mm

Weight:Around 0.5 kg to 1.5 kg

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101