描述

产品概述

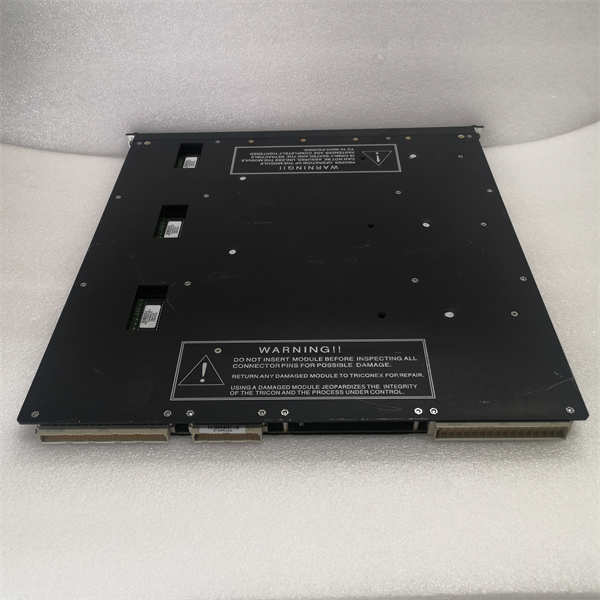

ABB PM633是一款多功能处理器模块,属于AC 800M PLC和DCS系列的核心组件,广泛应用于工业自动化控制领域。其设计目标是提供高性能计算能力、多协议通信支持及高可靠性,适用于电力、化工、制造业、建筑等复杂场景的控制需求。

技术参数

硬件配置

处理器:

双核ARM Cortex-A15(部分型号为32位RISC处理器,主频266 MHz)。

内存:4 GB RAM+16 GB闪存(可扩展至32 MB)。

接口:

通信端口:双冗余以太网(10/100 Mbps)、Profibus-DP、RS-485。

I/O扩展:支持本地I/O模块及远程I/O站,最大扩展至1024个物理I/O点。

尺寸与重量:200 mm×150 mm×45 mm,重量0.2-20 kg(不同型号差异)。

环境适应性

工作温度:-40°C至+70°C(扩展范围)。

湿度:5%-95%(无冷凝)。

防护等级:IP20(需配合机柜使用),抗振动与电磁干扰(符合IEC 61000-6标准)。

电源

输入电压:24 V DC(±15%),支持冗余电源输入。

核心功能特点

高性能控制

支持实时多任务操作系统(RTOS),处理速度达13 Hz至266 MHz,适用于复杂逻辑控制与数据采集。

兼容IEC 61131-3标准编程语言(梯形图、结构化文本等),内置PID控制、顺序控制等功能块库。

多协议通信

支持Modbus TCP、OPC UA、Profibus等协议,可与西门子、施耐德等第三方设备集成。

提供离线路径搜索功能,提前检测路径组合并优化物料传输逻辑。

冗余与容错

支持CPU双机热备冗余,切换时间<100 ms,确保系统高可用性。

内置故障诊断功能,实时监测模块状态、通信质量及I/O健康度。

工业级可靠性

符合IEC 61508 SIL2安全标准,适用于安全仪表系统(SIS)。

过流、过热保护机制,抗干扰设计,适应恶劣工业环境。

开放性与扩展性

支持闪存卡存储应用程序与数据,便于备份与恢复。

模块化设计,可通过添加功能卡扩展功能(如模拟量输入/输出)。

典型应用场景

工业自动化

电力系统:发电机、电动机控制及电网稳定性管理。

化工生产:反应釜温度、压力闭环控制。

过程控制

水处理:泵站、阀门自动化控制。

分布式系统:通过Profibus连接远程I/O站,监控泵站、阀门等设备。

建筑与能源

HVAC系统:空调、通风设备调节。

暖通空调:温度、湿度动态优化。

PM6301A

PM6301A

Product Overview

ABB PM633 is a multi-function processor module,which belongs to the core components of the AC 800M PLC and DCS series,and is widely used in the field of industrial automation control.Its design goal is to provide high-performance computing capabilities,multi-protocol communication support and high reliability,which is suitable for control needs in complex scenarios such as electricity,chemical industry,manufacturing,and construction.

Technical parameters

Hardware configuration

processor:

Dual-core ARM Cortex-A15(some models are 32-bit RISC processors,clocked at 266 MHz).

Memory:4 GB RAM+16 GB flash memory(scalable to 32 MB).

interface:

Communication ports:Dual redundant Ethernet(10/100 Mbps),Profibus-DP,RS-485.

I/O extension:supports local I/O modules and remote I/O stations,with a maximum expansion of 1024 physical I/O points.

Dimensions and weight:200 mm×150 mm×45 mm,weight 0.2-20 kg(differences of different models).

Environmental adaptability

Operating temperature:-40°C to+70°C(extended range).

Humidity:5%-95%(no condensation).

Protection level:IP20(need to be used with the cabinet),anti-vibration and electromagnetic interference(compliant with IEC 61000-6 standard).

power supply

Input voltage:24 V DC(±15%),support redundant power input.

Core functional features

High performance control

Supports real-time multi-tasking operating system(RTOS),with processing speeds up to 13 Hz to 266 MHz,suitable for complex logic control and data acquisition.

Compatible with IEC 61131-3 standard programming language(ladder diagram,structured text,etc.),it has a built-in functional block library such as PID control,sequential control,etc.

Multi-protocol communication

Supports Modbus TCP,OPC UA,Profibus and other protocols,and can be integrated with third-party devices such as Siemens and Schneider.

Provide offline path search function,detect path combinations in advance and optimize material transmission logic.

Redundancy and fault tolerance

Supports CPU dual-machine hot standby redundancy,switching time<100 ms,ensuring high system availability.

Built-in troubleshooting function to monitor module status,communication quality and I/O health in real time.

Industrial-grade reliability

Complies with IEC 61508 SIL2 safety standards and is suitable for safety instrumentation systems(SIS).

Overcurrent and overheating protection mechanism,anti-interference design,adapt to harsh industrial environments.

Openness and scalability

Supports flash memory card to store applications and data,making it easy to backup and restore.

Modular design,can be extended by adding function cards(such as analog input/output).

Typical application scenarios

Industrial automation

Power system:generator,motor control and grid stability management.

Chemical production:closed-loop control of reactor temperature and pressure.

Process control

Water treatment:automatic control of pump stations and valves.

Distributed system:Connect to remote I/O stations through Profibus to monitor pump stations,valves and other equipment.

Construction and Energy

HVAC system:air conditioning,ventilation equipment adjustment.

HVAC:Dynamic optimization of temperature and humidity.