描述

ABB PPC907BE 3BHE024577R0101产品详情

一、基本信息

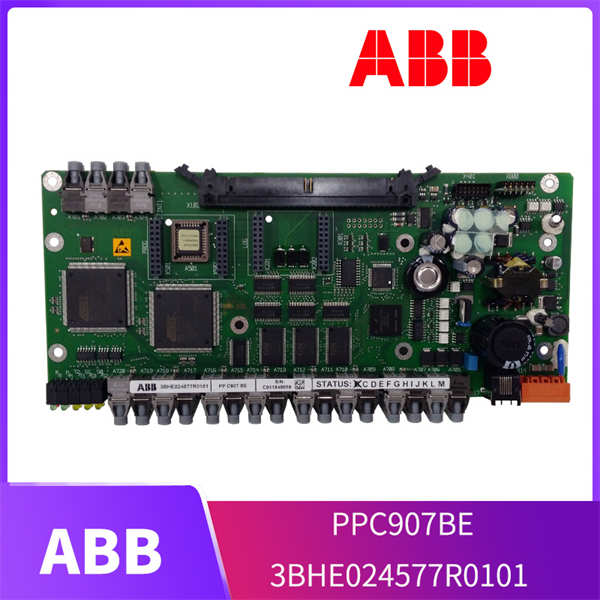

品牌与型号:ABB PPC907BE 3BHE024577R0101

产品类型:处理器模块

应用领域:广泛应用于工业自动化、电力系统、过程控制、制造业、能源管理、交通控制、建筑自动化等多个领域,是工业控制系统中不可或缺的核心组件。

二、技术规格

处理器性能

高性能处理器:搭载高性能处理器,具备强大的计算和处理能力,能够高效执行复杂的控制算法和运算任务,满足实时控制和数据处理的要求。

多核架构:采用多核处理器架构,提高并行处理能力和系统响应速度,可同时处理多个任务,提升整体性能。

存储与扩展

大容量存储器:配备大容量存储器,用于存储控制程序、历史数据和配置信息,支持长时间数据记录和复杂逻辑运算。

灵活扩展性:模块化设计支持扩展槽位,可连接其他模块和接口,适应不同规模系统的扩展需求。

通信接口

多种接口类型:提供以太网、串口、CAN总线、Modbus、Profibus等多种通信接口,支持与其他设备和系统的高效数据交换。

高速数据传输:支持高速数据传输协议,可快速传输大量数据,满足实时控制和数据采集需求。

信号处理

多类型信号支持:支持数字信号和模拟信号的输入输出,兼容多种传感器和执行器,实现灵活的系统集成。

信号增强功能:可扩展模拟量输入/输出通道、数字量输入/输出通道,增强设备通信和控制能力。

环境适应性

宽温工作范围:工作温度范围为-40℃至+70℃,适应极端工业环境。

防护等级:防护等级达到IP20(部分场景可达IP67),具备防尘防水能力,确保设备长期稳定运行。

电气参数

输入电压:DC 24V

功耗:最大约4.5瓦特

尺寸与重量:模块尺寸为90mm×30mm×25mm,重量约0.2kg,便于紧凑安装。

三、功能特点

实时监控与控制

实时数据采集:支持多通道数据同步采集,确保系统状态实时更新。

远程控制功能:通过网络连接实现远程监视和控制,提升运维效率。

数据管理与处理

数据存储与分析:管理设备运行状态、过程参数、故障信息等数据,支持历史数据查询和性能分析。

逻辑编程能力:支持可编程逻辑功能,用户可自定义控制策略,适应复杂应用场景。

安全与可靠性

冗余设计:关键组件采用冗余配置,提升系统容错能力。

安全保护机制:集成过流、过压、过温保护功能,确保设备安全运行。

易用性与维护性

模块化设计:支持热插拔功能,便于现场维护和升级。

故障诊断工具:内置自检程序,可快速定位故障模块,缩短停机时间。

四、典型应用场景

工业自动化

生产线控制:协调机械臂、传送带等设备,实现高精度生产流程。

机器人控制:支持多轴联动控制,提升机器人作业效率。

电力系统

发电监控:实时监测发电机组运行参数,优化发电效率。

输配电保护:快速响应电网故障,保障供电可靠性。

过程控制

化工生产:精确控制反应釜温度、压力等参数,确保产品质量。

制药工艺:满足GMP规范要求,实现无菌环境下的自动化生产。

3BHE024577R0101-PPC907BE

3BHE024577R0101-PPC907BE

ABB PPC907BE 3BHE024577R0101 Product Details

I.Basic Information

Brand and Model:ABB PPC907BE 3BHE024577R0101

Product Type:Processor Module

Application Field:Widely used in industrial automation,power systems,process control,manufacturing,energy management,traffic control,building automation and other fields,it is an indispensable core component in industrial control systems.

II.Technical Specifications

Processor Performance

High-performance processor:Equipped with a high-performance processor,it has powerful computing and processing capabilities,can efficiently execute complex control algorithms and computing tasks,and meet the requirements of real-time control and data processing.

Multi-core architecture:Adopting a multi-core processor architecture,it improves parallel processing capabilities and system response speed,can handle multiple tasks at the same time,and improves overall performance.

Storage and Expansion

Large-capacity memory:Equipped with large-capacity memory,it is used to store control programs,historical data and configuration information,and supports long-term data recording and complex logical operations.

Flexible scalability:The modular design supports expansion slots,which can be connected to other modules and interfaces to meet the expansion needs of systems of different sizes.

Communication interface

Multiple interface types:Provides multiple communication interfaces such as Ethernet,serial port,CAN bus,Modbus,Profibus,etc.,supporting efficient data exchange with other devices and systems.

High-speed data transmission:Supports high-speed data transmission protocol,can quickly transmit large amounts of data,and meet real-time control and data acquisition requirements.

Signal processing

Multiple signal support:Supports input and output of digital and analog signals,compatible with a variety of sensors and actuators,and realizes flexible system integration.

Signal enhancement function:Can expand analog input/output channels and digital input/output channels to enhance device communication and control capabilities.

Environmental adaptability

Wide temperature operating range:The operating temperature range is-40℃to+70℃,which is suitable for extreme industrial environments.

Protection level:The protection level reaches IP20(IP67 in some scenarios),with dust and water resistance,ensuring long-term stable operation of the equipment.

Electrical parameters

Input voltage:DC 24V

Power consumption:Maximum about 4.5 watts

Dimensions and weight:The module size is 90mm×30mm×25mm,and the weight is about 0.2kg,which is convenient for compact installation.

3.Features

Real-time monitoring and control

Real-time data acquisition:supports multi-channel data synchronous acquisition to ensure real-time update of system status.

Remote control function:remote monitoring and control through network connection to improve operation and maintenance efficiency.

Data management and processing

Data storage and analysis:manage equipment operation status,process parameters,fault information and other data,support historical data query and performance analysis.

Logic programming ability:supports programmable logic function,users can customize control strategy to adapt to complex application scenarios.

Safety and reliability

Redundant design:key components adopt redundant configuration to improve system fault tolerance.

Safety protection mechanism:integrated overcurrent,overvoltage and overtemperature protection functions to ensure safe operation of equipment.

Ease of use and maintainability

Modular design:supports hot-swap function,which is convenient for on-site maintenance and upgrade.

Fault diagnosis tool:built-in self-test program can quickly locate faulty modules and shorten downtime.

4.Typical application scenarios

Industrial automation

Production line control:coordinate robotic arms,conveyor belts and other equipment to achieve high-precision production processes.

Robot control:supports multi-axis linkage control to improve robot operation efficiency.

Power system

Power generation monitoring:Real-time monitoring of generator set operating parameters to optimize power generation efficiency.

Power transmission and distribution protection:Rapid response to power grid failures to ensure power supply reliability.

Process control

Chemical production:Accurately control parameters such as reactor temperature and pressure to ensure product quality.

Pharmaceutical process:Meet GMP specifications and achieve automated production in a sterile environment.