描述

一、产品概述

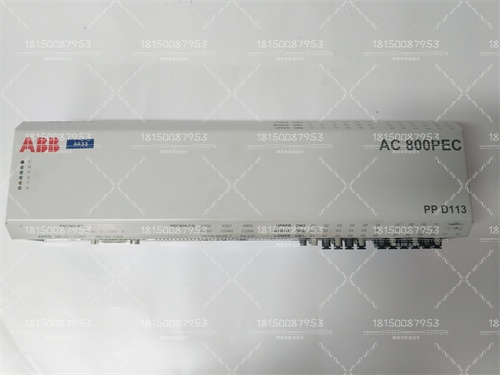

型号:PPD113B01-10-150000

订货号:3BHE023784R0123

类型:IGBT功率模块(集成驱动、保护和散热功能)

核心定位:

作为HVDC换流阀或STATCOM(静止同步补偿器)的核心元件,实现交直流电能转换或无功功率补偿。

支持高频开关(kHz级),降低谐波失真,提升系统效率。

适用于极端环境(如海上风电、高原地区),具备高可靠性和长寿命设计。

二、硬件规格

1.功率器件

核心元件:

采用ABB第三代高压IGBT芯片(如HP3或HP4系列),耐压等级≥15kV,额定电流≥1500A(具体参数需参考模块铭牌)。

集成反并联二极管(Free-Wheeling Diode,FWD),支持反向电流续流。

封装形式:

压接式封装(Press-Pack IGBT):

无引线设计,通过压力接触实现低电感、高散热性能。

适用于串联应用(如HVDC换流阀中多个模块串联至数百kV)。

尺寸:约400mm×200mm×100mm(长×宽×高,具体以实物为准)。

2.驱动电路

集成驱动板:

支持光纤通信,隔离高压与低压控制电路,抗电磁干扰(EMI)。

提供软开关控制(如零电压开关ZVS),减少开关损耗。

驱动电压:±15V(典型值),驱动电流:≥2A(峰值)。

保护功能:

过流保护(OC):通过退饱和检测(Desaturation Detection)快速关断IGBT(响应时间≤1μs)。

过压保护(OV):监测DC母线电压,触发保护动作(如关断或旁路)。

过热保护(OT):内置NTC温度传感器,温度超过阈值时降额运行或停机。

3.散热设计

散热结构:

双面冷却(Double-Sided Cooling):

上下表面均覆盖铜基板,直接与水冷板或热管接触,热阻≤0.02K/W。

水冷接口:

支持G1/4或M16螺纹接口,适配标准水冷系统(如ABB Hydrocool系列)。

冷却液流量:≥5L/min(推荐),入口温度:≤50°C。

热管理参数:

最大结温(Tj,max):150°C(持续运行需≤125°C)。

功率损耗(典型值):

导通损耗(Pcon):≤500W( 1500A,6kV)。

开关损耗(Psw):≤200W( 1kHz,1500A)。

4.机械与电气接口

机械接口:

模块底部设计有定位销和螺纹孔,便于与散热器或换流阀框架固定。

重量:约15kg(含驱动板和冷却结构)。

电气接口:

高压端:铜排输出(额定电流1500A,短时过载能力≥2000A/10s)。

低压控制端:光纤接口(ST或LC连接器),传输驱动信号和状态反馈。

三、软件与功能

1.控制模式

PWM调制:

支持空间矢量调制(SVPWM),提高直流电压利用率(≥98%)。

开关频率:可调(500Hz-5kHz),默认1kHz(平衡效率与谐波)。

同步控制:

通过PLL(锁相环)实现与电网电压同步,支持弱电网工况(短路比≥2)。

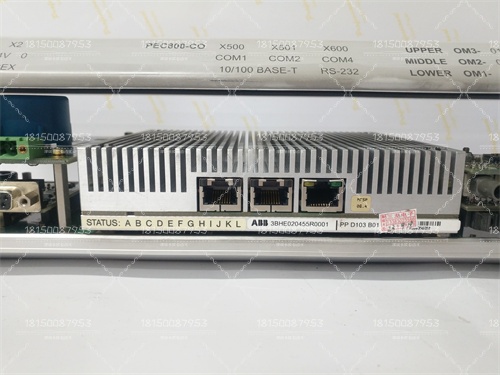

2.通信接口

光纤通信:

支持IEC 61850-9-2或ABB私有协议,与上层控制器(如HVDC控制保护系统)实时交互。

传输速率:≥100Mbps,延迟≤10μs。

可选接口:

调试接口:RS-485(用于参数配置和故障诊断)。

3.诊断与监测

状态反馈:

通过光纤传输IGBT结温、电流、电压等实时数据。

支持健康度评估(如SOH,State of Health),预测模块寿命。

故障记录:

内置Flash存储器,记录最近100次故障事件(时间戳、故障类型、参数值)。

四、典型应用场景

1.高压直流输电(HVDC)

背靠背换流站:

实现异步电网互联(如中国±800kV乌东德工程)。

模块串联数量:约100-200个(总电压±800kV)。

海上风电并网:

柔性直流输电(VSC-HVDC)减少海上平台空间占用。

模块需通过盐雾测试(IEC 60068-2-52)和振动测试(IEC 60068-2-64)。

2.柔性交流输电(FACTS)

STATCOM(静止同步补偿器):

动态补偿无功功率,提升电网电压稳定性(如钢铁厂、数据中心供电)。

响应时间:≤10ms(从指令到输出无功功率)。

SVC(静止无功补偿器):

与晶闸管控制电抗器(TCR)配合,实现宽范围无功调节。

1.Product Overview

Model:PPD113B01-10-150000

Order No.:3BHE023784R0123

Type:IGBT power module(integrated drive,protection and heat dissipation functions)

Core Positioning:

As the core component of HVDC converter valve or STATCOM(static synchronous compensator),it realizes AC/DC power conversion or reactive power compensation.

Supports high-frequency switching(kHz level),reduces harmonic distortion and improves system efficiency.

Suitable for extreme environments(such as offshore wind power and plateau areas),with high reliability and long life design.

2.Hardware Specifications

1.Power Devices

Core Components:

Adopt ABB’s third-generation high-voltage IGBT chip(such as HP3 or HP4 series),with a withstand voltage level of≥15kV and a rated current of≥1500A(refer to the module nameplate for specific parameters).

Integrated anti-parallel diode(Free-Wheeling Diode,FWD),supports reverse current flow.

Package form:

Press-Pack IGBT:

Leadless design,low inductance and high heat dissipation performance through pressure contact.

Suitable for series applications(such as multiple modules in HVDC converter valves connected in series to hundreds of kV).

Dimensions:about 400mm×200mm×100mm(length×width×height,the actual product shall prevail).

2.Drive circuit

Integrated drive board:

Supports optical fiber communication,isolates high-voltage and low-voltage control circuits,and resists electromagnetic interference(EMI).

Provides soft switching control(such as zero voltage switching ZVS)to reduce switching losses.

Drive voltage:±15V(typical value),drive current:≥2A(peak value).

Protection function:

Overcurrent protection(OC):Quickly shut down the IGBT through desaturation detection(Desaturation Detection)(response time≤1μs).

Overvoltage protection(OV):Monitors the DC bus voltage and triggers protection actions(such as shutdown or bypass).

Overheat protection(OT):Built-in NTC temperature sensor,derating or shutdown when temperature exceeds the threshold.

3.Heat dissipation design

Heat dissipation structure:

Double-Sided Cooling:

Both upper and lower surfaces are covered with copper substrates,directly in contact with water cooling plates or heat pipes,thermal resistance≤0.02K/W.

Water cooling interface:

Supports G1/4 or M16 threaded interface,suitable for standard water cooling systems(such as ABB Hydrocool series).

Coolant flow rate:≥5L/min(recommended),inlet temperature:≤50°C.

Thermal management parameters:

Maximum junction temperature(Tj,max):150°C(≤125°C for continuous operation).

Power loss(typical value):

Conduction loss(Pcon):≤500W( 1500A,6kV).

Switching loss(Psw):≤200W( 1kHz,1500A).

4.Mechanical and electrical interface

Mechanical interface:

The bottom of the module is designed with positioning pins and threaded holes to facilitate fixing with the radiator or converter valve frame.

Weight:about 15kg(including drive board and cooling structure).

Electrical interface:

High voltage end:copper busbar output(rated current 1500A,short-term overload capacity≥2000A/10s).

Low voltage control end:optical fiber interface(ST or LC connector),transmission of drive signal and status feedback.

III.Software and functions

1.Control mode

PWM modulation:

Support space vector modulation(SVPWM)to improve DC voltage utilization(≥98%).

Switching frequency:adjustable(500Hz-5kHz),default 1kHz(balance efficiency and harmonics).

Synchronous control:

Synchronize with grid voltage through PLL(phase-locked loop),support weak grid conditions(short circuit ratio≥2).

2.Communication interface

Fiber optic communication:

Supports IEC 61850-9-2 or ABB private protocol,and interacts with upper-level controllers(such as HVDC control and protection systems)in real time.

Transmission rate:≥100Mbps,delay≤10μs.

Optional interface:

Debug interface:RS-485(for parameter configuration and fault diagnosis).

3.Diagnosis and monitoring

Status feedback:

Transmits real-time data such as IGBT junction temperature,current,and voltage through optical fiber.

Supports health assessment(such as SOH,State of Health)and predicts module life.

Fault record:

Built-in Flash memory records the last 100 fault events(timestamp,fault type,parameter value).

IV.Typical application scenarios

1.High-voltage direct current transmission(HVDC)

Back-to-back converter station:

Realizes asynchronous power grid interconnection(such as China’s±800kV Wudongde project).

Number of modules in series:about 100-200(total voltage±800kV).

Offshore wind power grid connection:

Flexible direct current transmission(VSC-HVDC)reduces the space occupied by offshore platforms.

The module needs to pass the salt spray test(IEC 60068-2-52)and vibration test(IEC 60068-2-64).

2.Flexible alternating current transmission(FACTS)

STATCOM(static synchronous compensator):

Dynamically compensate reactive power and improve grid voltage stability(such as power supply for steel mills and data centers).

Response time:≤10ms(from command to output reactive power).

SVC(static VAR compensator):

Works with thyristor controlled reactor(TCR)to achieve wide range reactive power regulation.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101