描述

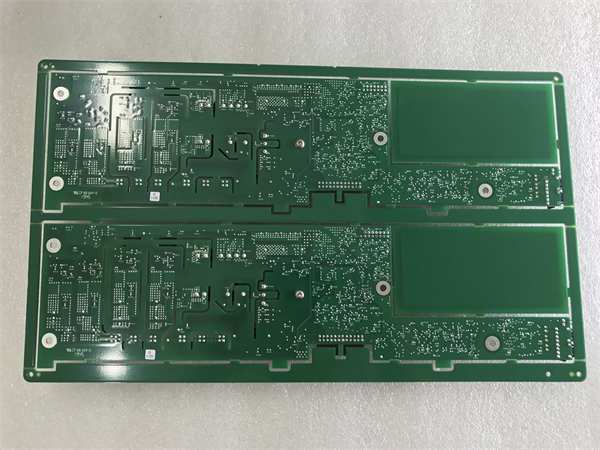

ABB PPD512A10-454000 3BHE040375R103E是一款高性能工业自动化模块,广泛应用于电力系统和工业控制领域。以下是其核心功能与技术特点的综合解析:

一、核心功能

静态励磁控制

专为发电机和电动机设计,通过调节励磁电流实现电压和电流输出的精确控制,确保电力系统稳定运行。

伺服控制处理器

支持高精度伺服驱动控制,适用于工业设备的调速、定位及保护功能,提供过载、过热、短路等多重保护。

二、技术特点

高性能处理能力

采用先进处理器技术,快速响应电力系统动态变化,支持复杂控制算法(如PID调节)。

支持多任务并行处理,满足高实时性工业场景需求。

可编程与灵活性

支持PLC编程语言,用户可自定义控制逻辑和算法。

模块化设计,可通过扩展接口适配不同工业协议(如CAN、Profibus、以太网)。

高可靠性与防护

经过严格环境测试,适应恶劣工业环境(如高温、振动)。

冗余设计与故障诊断功能,降低系统停机风险。

通信与集成能力

支持多种工业协议,便于与上位机、PLC及传感器设备无缝连接。

提供中央监控功能,实现远程状态监测与维护。

三、应用场景

电力系统

发电机励磁调节、电网电压稳定性控制。

风电场、变电站设备自动化管理。

工业自动化

伺服电机驱动控制、机器人运动轨迹规划。

包装机械、数控机床高精度定位。

能源与制造

石油开采设备监控、化工流程控制。

智能制造生产线动态调整与优化。

四、技术优势

精确控制逻辑:支持微分指令(PLS/PLF)和主控指令(MC/MCR),实现复杂时序逻辑控制。

扩展性:通过堆栈指令(MPS/MRD/MPP)支持多级嵌套结构,满足复杂系统设计需求。

抗干扰设计:隔离式信号输入与电源防护,符合工业电磁兼容标准。

五、兼容性与接口

输入/输出接口:支持模拟量(4-20mA、0-10V)与数字量(开关量)信号。

通信接口:以太网、CAN、Profibus等工业标准协议。

扩展接口:支持模块化扩展,如电源模块、数据采集模块等。

PPD512A10-150000

PPD517A3011 3BHE041576R3011

ABB PPD512A10-454000 3BHE040375R103E is a high-performance industrial automation module widely used in power systems and industrial control fields.The following is a comprehensive analysis of its core functions and technical features:

1.Core functions

Static excitation control

Designed for generators and motors,it achieves precise control of voltage and current output by adjusting the excitation current to ensure stable operation of the power system.

Servo control processor

Supports high-precision servo drive control,suitable for speed regulation,positioning and protection functions of industrial equipment,and provides multiple protections such as overload,overheating,and short circuit.

2.Technical features

High-performance processing capability

Adopts advanced processor technology to quickly respond to dynamic changes in power systems and support complex control algorithms(such as PID regulation).

Supports multi-task parallel processing to meet the needs of high real-time industrial scenarios.

Programmable and flexible

Supports PLC programming language,and users can customize control logic and algorithms.

Modular design,can adapt to different industrial protocols(such as CAN,Profibus,Ethernet)through expansion interfaces.

High reliability and protection

After rigorous environmental testing,it can adapt to harsh industrial environments(such as high temperature and vibration).

Redundant design and fault diagnosis functions reduce the risk of system downtime.

Communication and integration capabilities

Support multiple industrial protocols,which is convenient for seamless connection with host computers,PLCs and sensor devices.

Provide central monitoring functions to achieve remote status monitoring and maintenance.

III.Application scenarios

Power system

Generator excitation regulation,grid voltage stability control.

Automation management of wind farms and substation equipment.

Industrial automation

Servo motor drive control,robot motion trajectory planning.

High-precision positioning of packaging machinery and CNC machine tools.

Energy and manufacturing

Oil extraction equipment monitoring,chemical process control.

Dynamic adjustment and optimization of intelligent manufacturing production lines.

IV.Technical advantages

Precise control logic:Support differential instructions(PLS/PLF)and master control instructions(MC/MCR)to achieve complex sequential logic control.

Extensibility:Support multi-level nested structures through stack instructions(MPS/MRD/MPP)to meet the needs of complex system design.

Anti-interference design:isolated signal input and power protection,in line with industrial electromagnetic compatibility standards.

V.Compatibility and interface

Input/output interface:supports analog(4-20mA,0-10V)and digital(switch)signals.

Communication interface:Ethernet,CAN,Profibus and other industrial standard protocols.

Expansion interface:supports modular expansion,such as power module,data acquisition module,etc.