描述

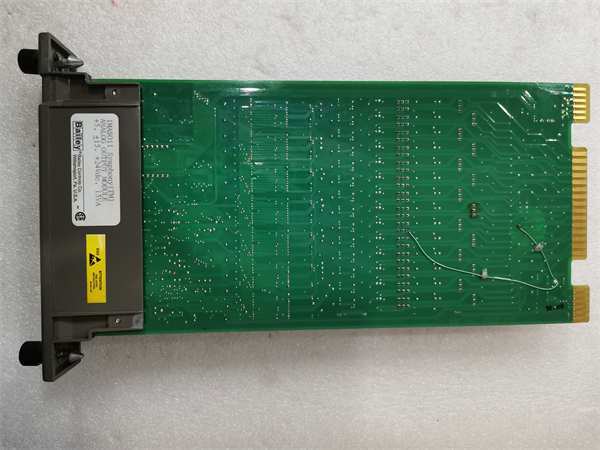

ABB RF533 3BSE014227R1是一款工业控制系统的核心组件,主要用于构建高可靠性和可扩展的自动化平台。以下是其产品简介:

一、产品定位与功能

类型

该产品为控制系统框架及子架组件,包含背板(BB510),适用于ABB Advant控制器450系列,支持模块化扩展,是工业自动化系统的核心支撑结构。

核心功能

-模块连接与通信:提供高效电气连接,支持多种电子模块(如I/O模块、电源模块)的安装与数据传输,确保系统通信的稳定性和实时性。

-机械支撑:采用坚固的压铸铝制外壳,具备高机械强度和抗振能力,适用于工业环境的严苛条件。

二、技术参数与设计特点

物理特性

-尺寸与重量:标准工业框架设计,净重16.25公斤,适配DIN导轨或机柜安装。

-接口兼容性:支持12SU标准背板接口,兼容ABB多系列模块化组件。

可靠性与安全性

-宽温工作:可在-40°C至70°C温度范围内稳定运行,适应复杂工业环境。

-冗余设计:支持热插拔维护,减少系统停机时间;模块化架构便于扩展和故障隔离。

扩展性

-协议支持:兼容Modbus、PROFIBUS等工业通信协议,可无缝集成至主流控制系统。

-电源管理:支持宽电压输入(24-220V),具备防反接和过流保护功能。

三、应用场景

工业自动化

用于制造业、电力、化工等领域的控制系统,如机器人运动控制、生产线监控、分布式I/O管理等。

能源与交通

应用于变电站自动化、轨道交通信号控制等对可靠性要求极高的场景。

过程控制

集成于ABB Advant OCS或AC460等控制系统,实现对温度、压力、流量等参数的精准监控与调节。

四、优势与认证

合规性

符合IEC 61131-3、UL等国际标准,通过CE、RoHS认证,确保安全与环保。

易维护性

-可视化指示:集成信号强度指示灯,支持远程和本地配置管理。

-模块化设计:简化故障排查,降低维护成本。

开放性

支持第三方设备接入,可通过网管平台实现集中配置与升级,提升系统灵活性。

RF522 3BSE000743R1

RF522 3BSE000743R1

ABB RF533 3BSE014227R1 is a core component of an industrial control system,mainly used to build a highly reliable and scalable automation platform.The following is a brief introduction to its product:

I.Product positioning and function

Type

This product is a control system frame and subframe component,including a backplane(BB510),suitable for ABB Advant controller 450 series,supports modular expansion,and is the core support structure of the industrial automation system.

Core function

-Module connection and communication:Provides efficient electrical connection,supports the installation and data transmission of a variety of electronic modules(such as I/O modules,power modules),and ensures the stability and real-time performance of system communication.

-Mechanical support:Adopts a sturdy die-cast aluminum housing with high mechanical strength and vibration resistance,suitable for harsh conditions in industrial environments.

II.Technical parameters and design features

Physical characteristics

-Dimensions and weight:Standard industrial frame design,net weight 16.25 kg,suitable for DIN rail or cabinet installation.

-Interface compatibility:supports 12SU standard backplane interface,compatible with ABB’s multi-series modular components.

Reliability and safety

-Wide temperature operation:can operate stably in the temperature range of-40°C to 70°C,adapting to complex industrial environments.

-Redundant design:supports hot-swap maintenance to reduce system downtime;modular architecture facilitates expansion and fault isolation.

Scalability

-Protocol support:compatible with industrial communication protocols such as Modbus and PROFIBUS,and can be seamlessly integrated into mainstream control systems.

-Power management:supports wide voltage input(24-220V),with anti-reverse connection and overcurrent protection functions.

III.Application scenarios

Industrial automation

Control systems used in manufacturing,power,chemical and other fields,such as robot motion control,production line monitoring,distributed I/O management,etc.

Energy and transportation

Applied to scenarios with extremely high reliability requirements such as substation automation and rail transit signal control.

Process control

Integrated into control systems such as ABB Advant OCS or AC460 to achieve accurate monitoring and adjustment of parameters such as temperature,pressure,and flow.

IV.Advantages and certifications

Compliance

Complies with international standards such as IEC 61131-3 and UL,and has passed CE and RoHS certifications to ensure safety and environmental protection.

Easy to maintain

-Visual indication:integrated signal strength indicator light,supports remote and local configuration management.

-Modular design:simplifies troubleshooting and reduces maintenance costs.

Openness

Supports access to third-party devices,and can achieve centralized configuration and upgrades through the network management platform to improve system flexibility.