描述

ABB Robotics DSQC 611(型号:3HAC13389-2-05)是专为ABB IRC5机器人控制柜设计的核心电源分配与电路控制模块,属于机器人自动化系统的关键组件。以下是其详细产品信息:

一、核心功能定位

电源分配与控制中枢:作为IRC5控制柜的核心配电模块,负责将主电源稳定分配至机器人驱动单元、传感器、控制柜内部散热系统等关键子系统,确保各组件供电同步与动作协调。

安全联锁与保护:内置工业级接触器和保护电路,支持机器人急停、安全门联锁等安全功能,在异常工况下快速切断危险回路,符合工业安全标准(如EN ISO 13849)。

状态监测与诊断:通过内置传感器实时监测电源电压、电流及回路状态,配合LED指示灯反馈运行状态,便于快速定位电源故障。

二、技术参数

电气特性:

输入电压:24V DC(兼容±15%电压波动,适应工业电网不稳定场景)。

输出通道:支持多路直流输出,为控制柜内驱动模块、逻辑电路等提供精准供电(具体通道数量需参考手册,通常为4-8路)。

触点容量:单路最大负载电流通常为5-10A(根据输出通道类型,支持继电器或晶体管输出),满足机器人电机驱动等大电流需求。

隔离设计:输入与输出电路电气隔离(隔离电压≥2500V AC),抗电磁干扰能力强,适应工业强电磁环境。

机械与环境参数:

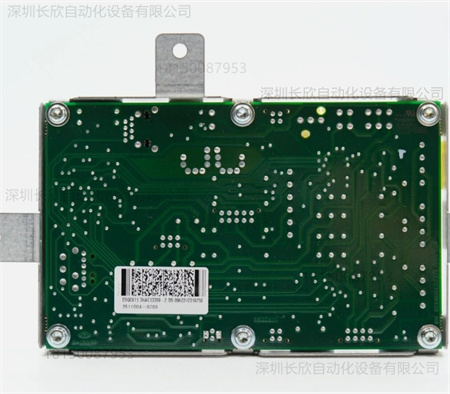

尺寸:紧凑型设计,约120mm×80mm×40mm(长×宽×高),适配IRC5控制柜内部狭小空间。

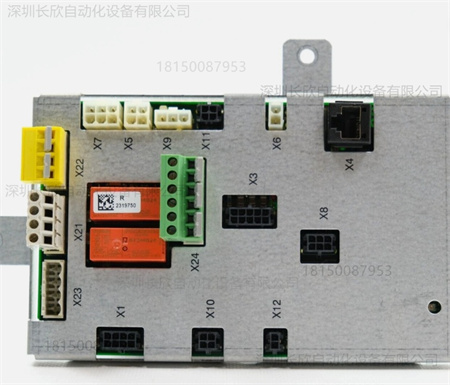

安装方式:支持DIN导轨安装或螺丝固定,兼容控制柜标准化安装布局。

防护等级:IP20(控制柜内部安装,防粉尘侵入)。

工作环境:温度-25℃~+60℃,湿度5%~95%(无冷凝),耐受振动(10-500Hz,振幅0.15mm)。

可靠性指标:

平均无故障时间(MTBF):≥100,000小时,满足工业连续生产需求。

冗余设计:关键电路采用冗余布局,降低单点故障风险。

三、功能特点

快速响应与切换:接触器动作响应时间≤10ms,支持机器人高频启停场景(如焊接、装配作业中的快速动作切换)。

安全集成:兼容ABB SafeMove安全系统,可通过安全信号联动控制电源通断,满足ISO 13850急停标准。

即插即用集成:与IRC5控制柜硬件和RobotWare软件无缝兼容,无需额外配置,上电即可识别并参与系统控制。

可视化诊断:前面板配备电源指示灯(PWR)、故障指示灯(FAULT)及通道状态灯,直观反馈模块运行状态。

The ABB Robotics DSQC 611(Model:3HAC13389-2-05)is a core power distribution and circuit control module designed specifically for the ABB IRC5 robot control cabinet.It is a key component of the robot automation system.The following is detailed product information:

I.Core Function

Power Distribution and Control Hub:As the core power distribution module of the IRC5 control cabinet,it is responsible for stably distributing main power to key subsystems such as the robot drive unit,sensors,and the control cabinet’s internal cooling system,ensuring synchronized power supply and coordinated operation of all components.

Safety Interlocks and Protection:Built-in industrial-grade contactors and protection circuits support safety functions such as robot emergency stop and safety door interlocks,quickly shutting off hazardous circuits under abnormal operating conditions and complying with industrial safety standards such as EN ISO 13849.

Condition Monitoring and Diagnostics:Built-in sensors monitor power supply voltage,current,and circuit status in real time,and LED indicators provide operational status feedback,making it easy to quickly locate power supply faults.

II.Technical Parameters

Electrical Characteristics:

Input Voltage:24V DC(compatible with±15%voltage fluctuations,suitable for unstable industrial power grids).Output Channels:Supports multiple DC outputs,providing precise power supply for drive modules,logic circuits,and other components within the control cabinet(refer to the manual for the specific number of channels;typically 4-8).

Contact Rating:Maximum load current per channel is typically 5-10A(depending on the output channel type,relay or transistor outputs are supported),meeting the high-current requirements of robotic motor drives and other applications.

Isolation Design:Input and output circuits are electrically isolated(isolation voltage≥2500V AC),providing strong immunity to electromagnetic interference and adapting to strong industrial electromagnetic environments.

Mechanical and Environmental Parameters:

Dimensions:Compact design,approximately 120mm×80mm×40mm(L×W×H),fits within the confined space of an IRC5 control cabinet.

Mounting Method:Supports DIN rail mounting or screw fixing,compatible with standard control cabinet mounting layouts.

Protection Rating:IP20(for installation inside a control cabinet,dust-proof).

Operating Environment:Temperature-25°C to+60°C,Humidity 5%to 95%(non-condensing),Vibration Tolerance(10-500Hz,0.15mm amplitude).

Reliability:

Mean Time Between Failures(MTBF):≥100,000 hours,meeting the demands of continuous industrial production.

Redundant Design:Critical circuits utilize redundant layouts to reduce the risk of single-point failures.

III.Features

Fast Response and Switching:Contactor actuation response time≤10ms,supporting high-frequency robot start/stop scenarios(such as rapid switching during welding and assembly operations).

Safety Integration:Compatible with the ABB SafeMove safety system,power on/off control can be linked via safety signals,meeting ISO 13850 emergency stop standards.

Plug-and-Play Integration:Seamlessly compatible with IRC5 control cabinet hardware and RobotWare software,requiring no additional configuration;the contactors recognize and participate in system control upon power-up.Visual diagnosis:The front panel is equipped with a power indicator(PWR),a fault indicator(FAULT),and a channel status light to provide intuitive feedback on module operating status.

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101