描述

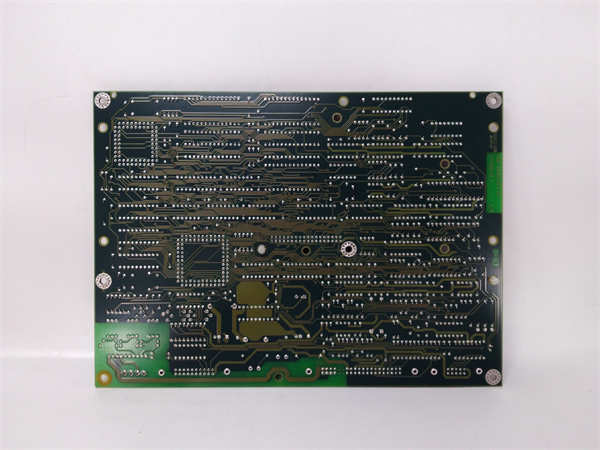

ABB SNAT602TAC是一款专为工业自动化设计的高性能控制模块,属于ABB控制系统系列的核心组件。以下是其产品简介:

一、产品定位与功能

SNAT602TAC主要用于ABB机器人控制系统,承担信号处理、逻辑控制及运动控制功能。其核心作用包括:

信号处理:通过高速数字信号处理器(DSP)实现高精度数据采集与实时处理。

逻辑控制:支持复杂逻辑运算,满足机器人路径规划、安全防护等需求。

运动控制:优化算法确保机器人运动的稳定性和精确性,适用于高动态场景。

二、技术特性

模块化设计

-支持灵活扩展,可根据实际需求组合不同功能模块(如信号输入/输出、通信接口等)。

-兼容ABB其他硬件(如DSQC系列模块),形成完整控制方案。

高性能与可靠性

-采用高速DSP与优化算法,处理速度可达工业级标准。

-符合严苛工业环境要求(如宽温、抗干扰),确保长期稳定运行。

通信与兼容性

-支持以太网、PROFIBUS等工业协议,可无缝集成至主流控制系统。

-兼容ABB机器人控制器(如ACS800系列),实现高效数据交互。

三、应用领域

工业机器人

-适用于焊接、装配、搬运等场景,提升运动精度与协同效率。

自动化生产线

-实现设备间联动控制,优化生产节拍与能耗。

仓储物流

-支持智能分拣与AGV导航,提升仓储管理效率。

四、设计优势

耐用性:采用加固型材料与密封设计,适应粉尘、高温等复杂环境。

易维护:支持热插拔与远程诊断,降低停机时间。

扩展性:预留接口支持未来功能升级,如增加传感器或执行器。

SNAT603CNT 61007041

SNAT603CNT 61007041

ABB SNAT602TAC is a high-performance control module designed for industrial automation and is a core component of the ABB control system series.The following is a brief introduction to its product:

I.Product positioning and functions

SNAT602TAC is mainly used in ABB robot control systems,and undertakes signal processing,logic control and motion control functions.Its core functions include:

Signal processing:high-precision data acquisition and real-time processing through a high-speed digital signal processor(DSP).

Logic control:supports complex logic operations to meet the needs of robot path planning,safety protection,etc.

Motion control:The optimization algorithm ensures the stability and accuracy of the robot’s movement and is suitable for high-dynamic scenarios.

II.Technical characteristics

Modular design

-Supports flexible expansion,and different functional modules(such as signal input/output,communication interface,etc.)can be combined according to actual needs.

-Compatible with other ABB hardware(such as DSQC series modules)to form a complete control solution.

High performance and reliability

-Using high-speed DSP and optimization algorithms,the processing speed can reach industrial standards.

-Meet the requirements of harsh industrial environments(such as wide temperature and anti-interference)to ensure long-term stable operation.

Communication and compatibility

-Supports industrial protocols such as Ethernet and PROFIBUS,and can be seamlessly integrated into mainstream control systems.

-Compatible with ABB robot controllers(such as the ACS800 series)to achieve efficient data interaction.

III.Application areas

Industrial robots

-Suitable for welding,assembly,handling and other scenarios to improve motion accuracy and collaborative efficiency.

Automated production lines

-Realize linkage control between equipment to optimize production rhythm and energy consumption.

Warehousing and logistics

-Support intelligent sorting and AGV navigation to improve warehouse management efficiency.

IV.Design advantages

Durability:Adopts reinforced materials and sealing design to adapt to complex environments such as dust and high temperature.

Easy maintenance:Supports hot plug and remote diagnosis to reduce downtime.

Scalability:Reserved interfaces support future function upgrades,such as adding sensors or actuators.