描述

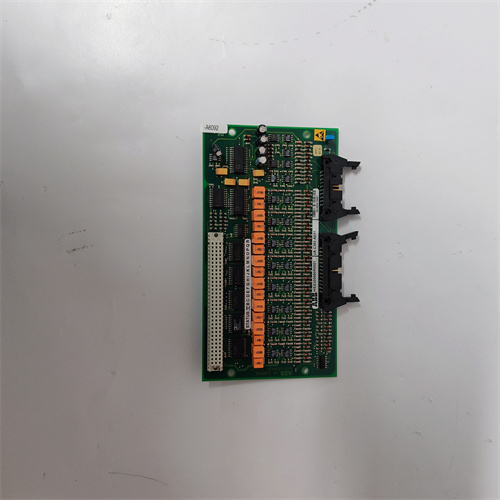

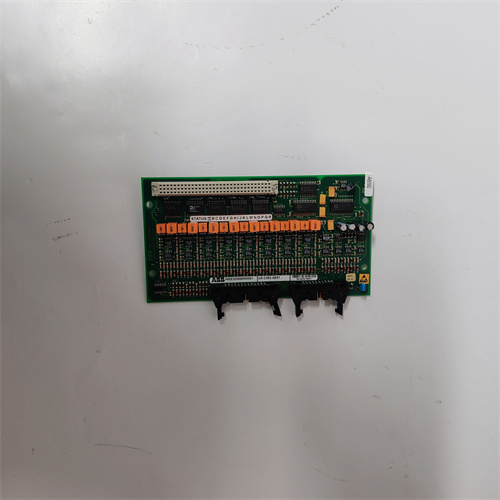

ABB UAC383AE01 HIEE300890R0001产品详情

一、基本信息

品牌:ABB(全球电气与自动化技术领导者,提供工业、能源、交通等领域解决方案)。

型号:UAC383AE01(HIEE300890R0001为其备件编号或内部物料编码)。

类型:ACS800系列变频器驱动控制单元(Drive Control Unit,DCU),属于ABB工业变频器核心组件。

用途:用于ACS800系列中压或低压变频器(如ACS800-07、ACS800-17等),实现电机调速、转矩控制、能量回馈等功能,广泛应用于冶金、矿山、造纸、电力等工业领域。

二、技术规格与功能

1.核心功能

变频器控制:

支持直接转矩控制(DTC)或矢量控制(VC),实现电机高精度调速(转速精度≤±0.1%)。

支持异步电机(IM)与同步电机(PM)的驱动,适配不同负载类型(如风机、泵、卷取机)。

能量回馈(可选):

具备四象限运行能力,可将制动能量回馈至电网,节能效率达95%以上(适用于起重、电梯等频繁制动场景)。

通信与集成:

内置Profibus-DP、Modbus RTU或Ethernet/IP接口,支持与PLC、DCS系统无缝集成。

支持ABB专用通信协议(如DriveWindow),实现远程监控与故障诊断。

2.性能参数

控制精度:

转速控制:≤±0.1%(DTC模式下)。

转矩控制:≤±3%(额定转矩)。

动态响应:

转矩响应时间:≤5 ms(DTC模式),适合高动态负载(如轧机、卷取机)。

环境适应性:

工作温度:-10℃至+50℃(扩展温度范围可达-20℃至+60℃,需选配)。

湿度:5%~95%(无冷凝),防护等级IP20(控制柜内安装)。

电气参数:

输入电压:380~690 VAC(三相,50/60 Hz,适配不同电网)。

输出频率:0~500 Hz(可编程设置)。

3.保护与冗余设计

保护功能:

过载保护:150%额定电流1分钟,200%额定电流3秒(自动切断)。

过压/欠压保护:输入电压波动±10%时正常工作,超出阈值时报警或停机。

短路保护:输出短路时快速响应(<10μs),避免设备损坏。

冗余设计:

支持双电源输入(可选),主电源故障时自动切换至备用电源。

控制单元可热插拔,在线更换不影响运行(需配置冗余模块)。

4.机械与接口

安装方式:

19英寸机架式安装(兼容ACS800系列控制柜),支持导轨或螺钉固定。

尺寸:约300×200×100 mm(具体以实物为准)。

接口类型:

数字输入/输出(DI/DO):8路DI、4路DO(可扩展)。

模拟输入/输出(AI/AO):2路AI(0~10 V或4~20 mA)、2路AO(可编程)。

编码器接口:支持增量式或绝对式编码器,实现闭环控制。

ABB UAC383AE01 HIEE300890R0001 Product Details

I.Basic Information

Brand:ABB(a global leader in electrical and automation technology,providing solutions in the fields of industry,energy,transportation,etc.).

Model:UAC383AE01(HIEE300890R0001 is its spare part number or internal material code).

Type:ACS800 series inverter drive control unit(Drive Control Unit,DCU),which is a core component of ABB industrial inverter.

Use:Used for ACS800 series medium voltage or low voltage inverters(such as ACS800-07,ACS800-17,etc.),to achieve motor speed regulation,torque control,energy feedback and other functions,widely used in metallurgy,mining,papermaking,power and other industrial fields.

II.Technical specifications and functions

1.Core functions

Inverter control:

Supports direct torque control(DTC)or vector control(VC)to achieve high-precision motor speed regulation(speed accuracy≤±0.1%).

Supports the drive of asynchronous motors(IM)and synchronous motors(PM),and is suitable for different load types(such as fans,pumps,and winders).

Energy feedback(optional):

With four-quadrant operation capability,it can feed back braking energy to the power grid,with energy saving efficiency of more than 95%(suitable for frequent braking scenarios such as cranes and elevators).

Communication and integration:

Built-in Profibus-DP,Modbus RTU or Ethernet/IP interface,supporting seamless integration with PLC and DCS systems.

Supports ABB dedicated communication protocols(such as DriveWindow)to achieve remote monitoring and fault diagnosis.

2.Performance parameters

Control accuracy:

Speedcontrol:≤±0.1%(in DTC mode).

Torque control:≤±3%(rated torque).

Dynamic response:

Torque response time:≤5 ms(DTC mode),suitable for high dynamic loads(such as rolling mills,coilers).

Environmental adaptability:

Working temperature:-10℃to+50℃(extended temperature range can reach-20℃to+60℃,optional).

Humidity:5%~95%(no condensation),protection level IP20(installed in the control cabinet).

Electrical parameters:

Input voltage:380~690 VAC(three-phase,50/60 Hz,adapted to different power grids).

Output frequency:0~500 Hz(programmable setting).

3.Protection and redundancy design

Protection function:

Overload protection:150%rated current for 1 minute,200%rated current for 3 seconds(automatic cut-off).

Overvoltage/undervoltage protection:normal operation when input voltage fluctuates±10%,alarm or shutdown when exceeding the threshold.

Short-circuit protection:Quick response(<10μs)when output is short-circuited to avoid equipment damage.

Redundant design:

Supports dual power input(optional),automatically switches to backup power when main power fails.

The control unit is hot-swappable,and online replacement does not affect operation(redundant modules need to be configured).

4.Mechanical and interface

Installation method:

19-inch rack installation(compatible with ACS800 series control cabinet),supports rail or screw fixing.

Dimensions:about 300×200×100 mm(specific details subject to the actual object).

Interface type:

Digital input/output(DI/DO):8 DI,4 DO(expandable).

Analog input/output(AI/AO):2 AI(0~10 V or 4~20 mA),2 AO(programmable).

Encoder interface:Supports incremental or absolute encoders to achieve closed-loop control.