描述

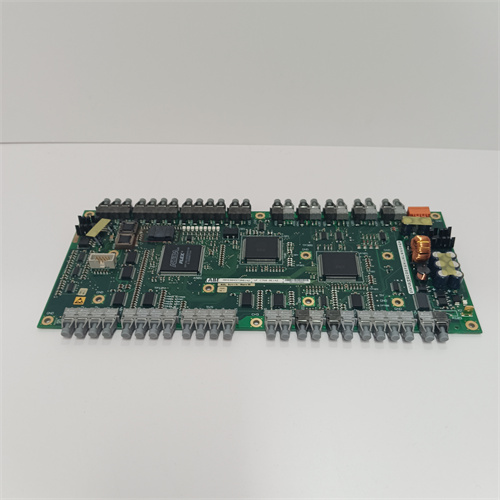

ABB UFC760BE142 3BHE004573R0142产品详情

一、基本信息

品牌与型号:ABB UFC760BE142 3BHE004573R0142

产品类型:控制器模块(电力通讯模块)

应用领域:广泛应用于工业自动化、能源管理、电力系统监控与控制等领域,尤其适用于需要高精度、高可靠性电力监控与控制的工业场景。

二、技术规格

核心功能

电力监控与控制:实时采集电力系统的电压、电流、功率等参数,执行保护性控制操作,确保系统稳定运行。

通信协议支持:兼容以太网、Modbus、Profibus DP等多种工业通信协议,支持逻辑独立双Profibus DP总线,可适配全部标准通信速率。

电气与物理参数

供电电压:支持115-220V宽幅电源输入,适应不同工业电源环境。

防护等级:外壳防护等级IP20,接线板防护等级IP2X,符合EN 50022-35导轨安装标准。

环境适应性:工作温度范围0-55℃,存储温度-20至+85℃,可在复杂工业环境中稳定运行。

接口与扩展性

数字输入输出:配备8路数字输入和4路测试输出,安全等级达SIL 3/PL e/Cat.4。

信号指示:通过LED实时显示工作状态与故障诊断信息,支持热插拔功能。

模块化设计:采用导轨紧固安装方式,支持与其他ABB设备无缝集成,形成完整控制系统。

三、功能特点

高精度控制

处理能力:基于高性能处理器架构,实现复杂控制算法的毫秒级响应。

采样稳定性:采用滤波技术消除共模电压干扰,确保模拟量采样精度优于0.1%。

通信可靠性

协议兼容性:支持IEC 61850等电力行业标准协议,实现与SCADA系统的双向数据交互。

总线冗余:双Profibus DP总线设计支持热备份,通信中断时间<10ms。

安全防护体系

电气安全:内置过压/过流保护电路,24V DC电源端子支持±20%电压波动。

故障诊断:通过服务端口(RS-232)可读取详细故障代码,支持远程维护。

四、应用场景

工业自动化产线

设备控制:协调机器人系统、数控机床等设备的同步运行,定位精度达±0.01mm。

数据采集:同步处理128通道模拟信号,数据刷新周期<10ms。

能源管理系统

电网监控:实时监测10kV配电系统的三相不平衡度,电压波动检测精度0.5%。

能效优化:通过功率因数补偿算法,使系统效率提升8-12%。

ABB UFC760BE142 3BHE004573R0142 Product Details

I.Basic Information

Brand and Model:ABB UFC760BE142 3BHE004573R0142

Product Type:Controller Module(Power Communication Module)

Application Fields:Widely used in industrial automation,energy management,power system monitoring and control,etc.,especially suitable for industrial scenarios that require high-precision and high-reliability power monitoring and control.

II.Technical Specifications

Core Functions

Power Monitoring and Control:Real-time collection of voltage,current,power and other parameters of the power system,execution of protective control operations,and ensuring stable operation of the system.

Communication Protocol Support:Compatible with multiple industrial communication protocols such as Ethernet,Modbus,Profibus DP,etc.,supports logically independent dual Profibus DP buses,and can adapt to all standard communication rates.

Electrical and Physical Parameters

Power Supply Voltage:Supports 115-220V wide power input to adapt to different industrial power supply environments.

Protection level:IP20 for the housing and IP2X for the terminal block,in compliance with the EN 50022-35 rail installation standard.

Environmental adaptability:Operating temperature range 0-55°C,storage temperature-20 to+85°C,can operate stably in complex industrial environments.

Interface and scalability

Digital input and output:Equipped with 8 digital inputs and 4 test outputs,with a safety level of SIL 3/PL e/Cat.4.

Signal indication:Real-time display of working status and fault diagnosis information through LED,supporting hot-swap function.

Modular design:Adopts rail fastening installation method,supports seamless integration with other ABB equipment to form a complete control system.

III.Functional features

High-precision control

Processing capability:Based on high-performance processor architecture,it realizes millisecond response of complex control algorithms.

Sampling stability:Filtering technology is used to eliminate common-mode voltage interference to ensure that the analog sampling accuracy is better than 0.1%.

Communication reliability

Protocol compatibility:Supports IEC 61850 and other power industry standard protocols to achieve two-way data interaction with SCADA systems.

Bus redundancy:Dual Profibus DP bus design supports hot backup,communication interruption time<10ms.

Safety protection system

Electrical safety:Built-in overvoltage/overcurrent protection circuit,24V DC power terminal supports±20%voltage fluctuation.

Fault diagnosis:Detailed fault codes can be read through the service port(RS-232),supporting remote maintenance.

IV.Application scenarios

Industrial automation production line

Equipment control:Coordinate the synchronous operation of robot systems,CNC machine tools and other equipment,with a positioning accuracy of±0.01mm.

Data acquisition:Synchronous processing of 128-channel analog signals,data refresh cycle<10ms.

Energy management system

Grid monitoring:Real-time monitoring of the three-phase imbalance of the 10kV distribution system,with a voltage fluctuation detection accuracy of 0.5%.

Energy efficiency optimization:Through the power factor compensation algorithm,the system efficiency is improved by 8-12%.