描述

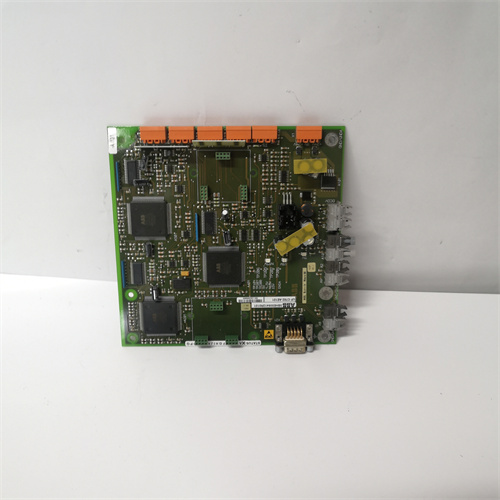

ABB UFC762AE101 3BHE006412R0101产品详情

一、基本信息

品牌与型号:ABB UFC762AE101 3BHE006412R0101

产品类型:伺服驱动模块

应用领域:该模块广泛应用于工业自动化和控制系统中,用于控制和驱动伺服电机,满足高精度运动控制需求。

二、技术规格

伺服控制功能

控制模式:支持速度控制、位置控制和扭矩控制三种模式,通过先进的控制算法实现精确的运动控制。

动态响应:高性能处理能力结合反馈系统,可实现高动态响应,确保伺服电机在复杂工况下的稳定运行。

多轴控制能力

轴数扩展:部分型号支持多轴同步控制,可同时驱动多个伺服电机,适用于多轴联动的高精度应用场景。

协同精度:多轴系统通过实时数据交互,保证各轴运动的同步误差低于±0.01mm。

接口与通信

通信协议:集成以太网、Modbus、CAN总线等工业通信接口,支持与主流PLC/DCS系统的无缝对接。

编码器接口:配备高分辨率编码器接口,可连接增量式或绝对式编码器,实现亚微米级位置反馈。

环境适应性

防护等级:模块外壳符合IP20标准,接线端子防护等级达IP2X,适应工业现场粉尘环境。

工作温度:可在0℃至55℃范围内稳定运行,短期耐受极限温度达70℃。

三、功能特点

高精度控制

采样精度:模拟量采样精度优于0.1%,位置控制分辨率达16位。

滤波技术:采用数字滤波算法,有效抑制共模电压干扰,保障信号稳定性。

集成与维护

模块化设计:支持导轨安装,兼容35mm标准导轨系统,便于快速部署与扩展。

诊断工具:内置自诊断程序,可通过LED指示灯或通信接口实时显示故障代码。

远程管理:支持远程监控和维护功能,用户可通过专用软件进行参数配置和状态监测。

安全与防护

电气安全:具备过压/过流保护功能,24V DC电源端子耐受±20%电压波动。

冗余设计:关键电路采用冗余架构,MTBF(平均无故障时间)超过10万小时。

四、应用场景

工业机器人

协作控制:实现六轴机器人关节的精确同步运动,重复定位精度±0.02mm。

轨迹规划:支持S型加减速曲线,保障机械臂运行的平稳性与效率。

自动化生产线

同步控制:在印刷、包装等设备中,实现多伺服轴的相位同步,误差<±0.1°。

张力控制:通过扭矩闭环控制,保持卷材张力波动范围<±1%。

高端装备制造

数控机床:配合直线电机实现微米级进给精度,表面粗糙度Ra≤0.4μm。

半导体设备:在晶圆传输系统中,定位精度达±0.5μm,满足洁净室Class 100要求。

ABB UFC762AE101 3BHE006412R0101 Product Details

I.Basic Information

Brand and Model:ABB UFC762AE101 3BHE006412R0101

Product Type:Servo Drive Module

Application Area:This module is widely used in industrial automation and control systems to control and drive servo motors to meet the needs of high-precision motion control.

II.Technical Specifications

Servo Control Function

Control Mode:Supports three modes:speed control,position control and torque control,and achieves precise motion control through advanced control algorithms.

Dynamic Response:High-performance processing capabilities combined with feedback systems can achieve high dynamic response and ensure stable operation of servo motors under complex working conditions.

Multi-axis Control Capability

Axis Expansion:Some models support multi-axis synchronous control and can drive multiple servo motors at the same time,which is suitable for high-precision application scenarios of multi-axis linkage.

Cooperative Accuracy:The multi-axis system interacts with real-time data to ensure that the synchronization error of each axis movement is less than±0.01mm.

Interface and communication

Communication protocol:Integrates industrial communication interfaces such as Ethernet,Modbus,and CAN bus,and supports seamless connection with mainstream PLC/DCS systems.

Encoder interface:Equipped with a high-resolution encoder interface,it can connect incremental or absolute encoders to achieve sub-micron position feedback.

Environmental adaptability

Protection level:The module housing meets the IP20 standard,and the terminal protection level reaches IP2X,which is suitable for industrial dust environments.

Working temperature:It can operate stably in the range of 0℃to 55℃,and the short-term tolerance limit temperature reaches 70℃.

III.Functional features

High-precision control

Sampling accuracy:The analog sampling accuracy is better than 0.1%,and the position control resolution is 16 bits.

Filtering technology:Digital filtering algorithm is used to effectively suppress common-mode voltage interference and ensure signal stability.

Integration and maintenance

Modular design:Supports rail installation,compatible with 35mm standard rail system,and is easy to deploy and expand quickly.

Diagnostic tool:Built-in self-diagnostic program,which can display fault codes in real time through LED indicators or communication interfaces.

Remote management:supports remote monitoring and maintenance functions.Users can configure parameters and monitor status through dedicated software.

Safety and protection

Electrical safety:With overvoltage/overcurrent protection function,the 24V DC power terminal can withstand±20%voltage fluctuations.

Redundant design:The key circuit adopts a redundant architecture,and the MTBF(mean time between failures)exceeds 100,000 hours.

IV.Application scenarios

Industrial robots

Collaborative control:Realize precise synchronous movement of six-axis robot joints,with a repeat positioning accuracy of±0.02mm.

Trajectory planning:Support S-shaped acceleration and deceleration curves to ensure the stability and efficiency of the robot arm operation.

Automated production line

Synchronous control:In printing,packaging and other equipment,realize phase synchronization of multiple servo axes with an error of<±0.1°.

Tension control:Through torque closed-loop control,keep the coil tension fluctuation range<±1%.

High-end equipment manufacturing

CNC machine tools:Cooperate with linear motors to achieve micron-level feed accuracy,with a surface roughness Ra≤0.4μm.

Semiconductor equipment:In the wafer transfer system,the positioning accuracy reaches±0.5μm,meeting the clean room Class 100 requirements.