描述

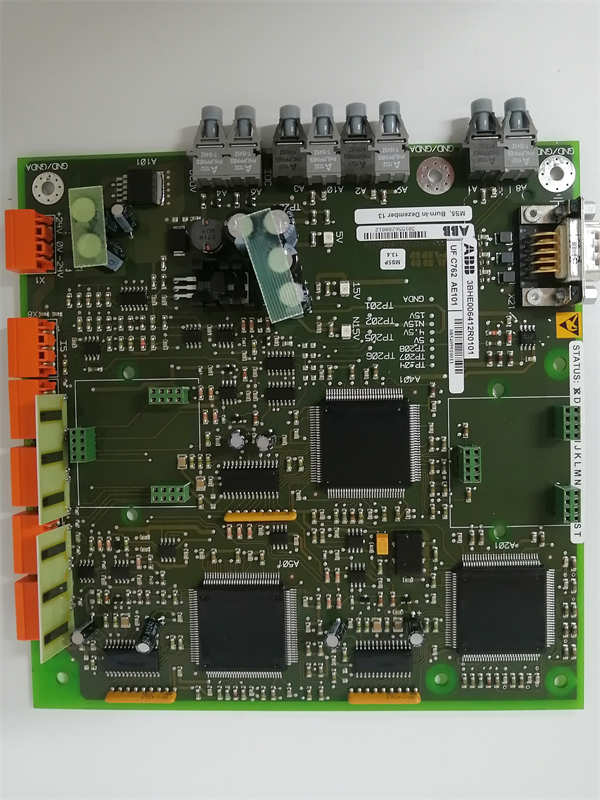

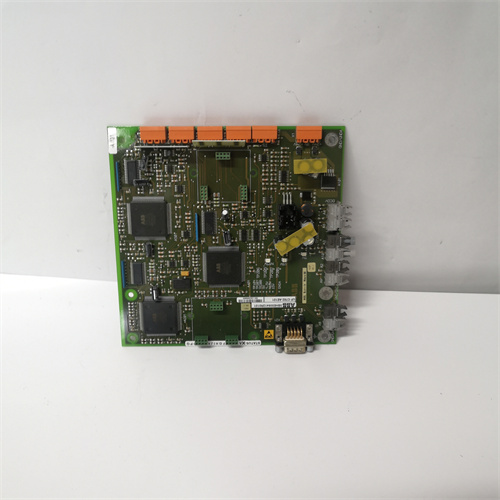

ABB UFC762AE101 3BHE006412R0101是一款高性能的伺服驱动模块,专为工业自动化和控制系统中伺服电机的精确控制而设计,以下为其产品详情:

核心功能

伺服控制:支持速度控制、位置控制和扭矩控制三种模式,可实现精确的运动控制,满足工业自动化中对高精度定位和动态响应的需求。

多轴协同:模块支持多轴控制功能,可同时驱动多个伺服电机,适用于需要复杂运动轨迹或同步控制的场景,如数控机床、机器人等。

闭环反馈:内置编码器接口,可连接伺服电机编码器实现位置反馈,形成闭环控制系统,提升运动控制的稳定性和精度。

技术特性

高性能处理:采用高性能处理器和反馈系统,具备快速动态响应能力,可实时调整控制参数以适应负载变化,确保运动过程的平稳性。

通信兼容性:支持以太网、Modbus、CAN总线等多种通信接口,可与PLC、DCS等控制系统无缝集成,兼容主流工业网络协议。

防护设计:模块具备特定防护等级,可抵御灰尘、湿气等环境干扰,适应工业现场恶劣环境,延长设备使用寿命。

自诊断功能:内置故障检测机制,可实时监测系统状态并生成报警信息,支持远程诊断,便于快速定位和解决故障。

应用领域

工业机器人:为机器人关节提供精确运动控制,支持多轴协同作业,提升生产效率和产品质量。

自动化装配线:实现装配过程中零部件的精准定位和快速搬运,优化生产流程,降低人工干预需求。

数控机床:控制主轴和进给轴的运动,确保加工精度和表面质量,适用于复杂零件的高精度加工。

风力涡轮机:调节叶片角度和转速,优化风能捕获效率,提升发电系统的稳定性和可靠性。

医疗设备:驱动精密运动部件,如手术机器人、影像扫描设备等,保障医疗操作的准确性和安全性。

印刷设备:控制纸张传输和印刷头运动,实现高精度套印和色彩管理,提升印刷质量和生产效率。

产品优势

高可靠性:模块化设计结合工业级元器件,确保长时间稳定运行,降低维护成本。

易用性:提供直观的配置界面和编程工具,支持参数快速设置和模式切换,降低使用门槛。

可扩展性:支持多轴扩展和通信协议定制,可灵活集成到现有系统中,适应未来升级需求。

ABB UFC762AE101 3BHE006412R0101 is a high-performance servo drive module designed for precise control of servo motors in industrial automation and control systems.The following are its product details:

Core functions

Servo control:supports three modes of speed control,position control and torque control,which can achieve precise motion control and meet the needs of high-precision positioning and dynamic response in industrial automation.

Multi-axis collaboration:The module supports multi-axis control functions and can drive multiple servo motors at the same time.It is suitable for scenarios that require complex motion trajectories or synchronous control,such as CNC machine tools,robots,etc.

Closed-loop feedback:Built-in encoder interface,which can be connected to the servo motor encoder to achieve position feedback,form a closed-loop control system,and improve the stability and accuracy of motion control.

Technical features

High-performance processing:Adopting high-performance processors and feedback systems,it has fast dynamic response capabilities,can adjust control parameters in real time to adapt to load changes,and ensure the smoothness of the motion process.

Communication compatibility:Supports multiple communication interfaces such as Ethernet,Modbus,CAN bus,etc.,can be seamlessly integrated with control systems such as PLC and DCS,and is compatible with mainstream industrial network protocols.

Protection design:The module has a specific protection level,which can resist environmental interference such as dust and moisture,adapt to the harsh environment of industrial sites,and extend the service life of the equipment.

Self-diagnosis function:The built-in fault detection mechanism can monitor the system status in real time and generate alarm information,support remote diagnosis,and facilitate rapid positioning and troubleshooting.

Application areas

Industrial robots:Provide precise motion control for robot joints,support multi-axis collaborative operations,and improve production efficiency and product quality.

Automated assembly lines:Realize accurate positioning and rapid handling of parts during assembly,optimize production processes,and reduce the need for manual intervention.

CNC machine tools:Control the movement of the spindle and feed axis to ensure processing accuracy and surface quality,and are suitable for high-precision processing of complex parts.

Wind turbines:Adjust the blade angle and speed,optimize the efficiency of wind energy capture,and improve the stability and reliability of the power generation system.

Medical equipment:Drive precision moving parts,such as surgical robots,image scanning equipment,etc.,to ensure the accuracy and safety of medical operations.

Printing equipment:Control paper transmission and print head movement to achieve high-precision overprinting and color management,and improve printing quality and production efficiency.

Product advantages

High reliability:modular design combined with industrial-grade components ensures long-term stable operation and reduces maintenance costs.

Ease of use:provides an intuitive configuration interface and programming tools,supports quick parameter setting and mode switching,and reduces the threshold for use.

Scalability:supports multi-axis expansion and communication protocol customization,and can be flexibly integrated into existing systems to adapt to future upgrade needs.