描述

一、产品定位与核心功能

1.目标应用场景

中小型水力发电:

适用于单机容量1MW-50MW的水轮发电机组,在水位波动、负荷突变等工况下,快速调整励磁电流,维持机端电压恒定,避免电压崩溃或设备过载。

火力与燃气发电:

用于燃煤、燃气蒸汽轮机发电机组,优化无功功率分配,减少厂用电损耗,提升机组并网运行的稳定性。

分布式能源与微电网:

在光伏+储能、风力发电+柴油发电机等混合系统中,协调多台发电机的无功输出,实现微电网的电压平衡。

工业备用电源:

为钢铁、化工、数据中心等行业的柴油发电机组提供快速励磁响应,确保市电中断时无缝切换,保障关键负载供电连续性。

2.核心功能

自动电压调节(AVR):

通过PID控制算法,实时监测发电机机端电压,调整励磁电流,使电压波动范围控制在±0.5%以内(远优于国标±1%要求)。

功率因数控制(PFC):

根据电网需求设定目标功率因数(如0.9滞后),自动调节无功功率输出,减少线路损耗,提升电网传输效率。

无功功率分配(Q Sharing):

在多台发电机并联运行时,按容量比例分配无功负荷,避免某台机组过载或欠载,延长设备使用寿命。

低频振荡抑制(PSS):

内置电力系统稳定器(PSS),通过附加励磁控制信号,抑制电网低频振荡(频率0.1-2.5Hz),提升系统动态稳定性。

故障保护与记录:

监测过励磁、欠励磁、失步、通信中断等故障,触发报警或跳闸,并记录故障时间、类型及参数,便于事后分析。

二、技术规格与性能参数

1.电气参数

输入信号:

电压信号:3相AC 100V(机端电压),精度±0.1%。

电流信号:3相AC 5A(定子电流),用于功率因数计算。

同步信号:1路AC/DC(用于相位同步,确保并网时相位一致)。

输出参数:

励磁电流:0-20A(连续可调),适配大多数中小型发电机励磁绕组。

励磁电压:0-300V(直流),响应时间<10ms,满足快速励磁需求。

控制精度:

电压调节精度:±0.2%FS(静态),±0.5%FS(动态)。

无功功率分配误差:±3%(多台机组并联时)。

2.硬件配置

处理器:

采用32位ARM Cortex-M7处理器,主频200MHz,处理速度比传统单片机快10倍,支持复杂控制算法实时运行。

存储容量:

Flash存储器:4MB(用于程序存储)。

RAM存储器:1MB(用于数据缓存)。

EEPROM存储器:256KB(用于故障记录、参数备份)。

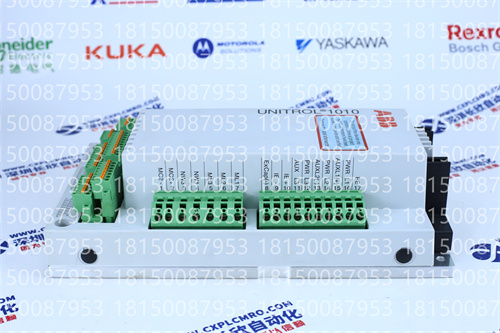

通信接口:

以太网接口:1路RJ45(10/100Mbps),支持Modbus TCP、IEC 61850协议,可与SCADA系统、DCS系统集成。

串行接口:2路RS485(Modbus RTU)、1路RS232(调试接口),兼容老旧设备升级。

硬接线接口:8路DI(可编程为启动、停止、复位等),4路DO(用于报警、跳闸、状态指示)。

3.环境适应性

工作温度:

-20℃至+60℃(存储温度:-40℃至+85℃),适应高寒地区(如东北水电站)或高温车间(如火电厂汽机房)。

湿度:

5%-95%RH(无凝露),耐受潮湿环境(如沿海风电场)。

抗振动:

通过IEC 60068-2-6标准振动测试(频率10-55Hz,振幅1.5mm),确保在发电机振动环境下稳定运行。

防护等级:

IP42(标准版),适用于控制柜内安装;可选IP54防护罩(需单独订购),用于户外或粉尘环境。

I.Product Positioning and Core Functions

1.Target Application Scenarios

Small and Medium-Sized Hydropower Generation:

Applicable to hydropower generators with a single unit capacity of 1MW-50MW.It rapidly adjusts the excitation current to maintain constant terminal voltage under conditions such as water level fluctuations and sudden load changes,preventing voltage collapse or equipment overload.

Fuel and Gas Power Generation:

Applicable to coal-fired and gas-fired steam turbine generators,optimizing reactive power distribution,reducing auxiliary power losses,and improving grid-connected operation stability.

Distributed Energy and Microgrids:

In hybrid systems such as photovoltaic+energy storage and wind power+diesel generators,it coordinates the reactive power output of multiple generators to achieve voltage balance in the microgrid.

Industrial Backup Power:

Provides fast excitation response for diesel generators in industries such as steel,chemical,and data centers,ensuring seamless switchover during utility power outages and ensuring continuous power supply to critical loads.2.Core Functions

Automatic Voltage Regulation(AVR):

Using a PID control algorithm,it monitors generator terminal voltage in real time and adjusts the excitation current to keep voltage fluctuations within±0.5%(far exceeding the national standard requirement of±1%).

Power Factor Control(PFC):

It sets a target power factor(e.g.,0.9 with hysteresis)based on grid demand and automatically adjusts reactive power output,reducing line losses and improving grid transmission efficiency.

Reactive Power Sharing(Q Sharing):

When multiple generators operate in parallel,it distributes reactive load based on capacity ratio,preventing overload or underload of any unit and extending equipment life.

Slow-Frequency Oscillation Suppression(PSS):

The built-in Power System Stabilizer(PSS)suppresses low-frequency grid oscillations(0.1-2.5Hz)by providing additional excitation control signals,improving system dynamic stability.Fault Protection and Recording:

Monitors faults such as overexcitation,underexcitation,loss of step,and communication interruption,triggering alarms or tripping,and recording fault time,type,and parameters for subsequent analysis.

II.Technical Specifications and Performance Parameters

1.Electrical Parameters

Input Signal:

Voltage:3-phase AC 100V(generator voltage),accuracy±0.1%.

Current:3-phase AC 5A(stator current),used for power factor calculation.

Synchronization Signal:1 AC/DC(for phase synchronization,ensuring phase alignment during grid connection).

Output Parameters:

Excitation Current:0-20A(continuously adjustable),suitable for most small and medium-sized generator excitation windings.

Excitation Voltage:0-300V(DC),response time<10ms,meeting fast excitation requirements.

Control Accuracy:

Voltage Regulation Accuracy:±0.2%FS(static),±0.5%FS(dynamic).Reactive power distribution error:±3%(when multiple units are connected in parallel).

2.Hardware Configuration

Processor:

32-bit ARM Cortex-M7 processor,200MHz clock speed,10 times faster than traditional microcontrollers,supporting real-time execution of complex control algorithms.

Memory Capacity:

Flash Memory:4MB(for program storage).

RAM Memory:1MB(for data cache).

EEPROM Memory:256KB(for fault logging and parameter backup).

Communication Interfaces:

Ethernet Interface:1 RJ45(10/100Mbps),supporting Modbus TCP and IEC 61850 protocols,enabling integration with SCADA and DCS systems.

Serial Interface:2 RS485(Modbus RTU),1 RS232(debugging interface),compatible with legacy equipment upgrades.

Hardwire Interfaces:8 DI(programmable for start,stop,reset,etc.),4 DO(for alarm,trip,and status indication).3.Environmental Adaptability

Operating Temperature:

-20°C to+60°C(Storage Temperature:-40°C to+85°C),suitable for use in cold regions(such as hydropower stations in Northeast China)or high-temperature workshops(such as turbine rooms in thermal power plants).

Humidity:

5%-95%RH(non-condensing),suitable for use in humid environments(such as coastal wind farms).

Vibration Resistance:

Passes IEC 60068-2-6 vibration testing(frequency 10-55Hz,amplitude 1.5mm),ensuring stable operation in generator vibration environments.

Protection Rating:

IP42(standard version),suitable for installation in a control cabinet;optional IP54 protective cover(ordered separately)for use outdoors or in dusty environments.

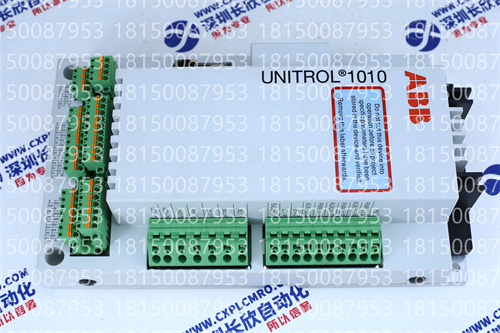

ABB Model: GBU72 3BHE055094R0002 Model: 3BHE055094R0002 GBU72 Model: GBU72 Model: 3BHE055094R0002 Model: 3BHE031197R0001 Model: 3BHB030310R0001 Model: 73BHE055094R0002 GBU72 Model: 73BHE055094R0002 Model: GBU72 Model: ABB PCS6000 PRODUCT FAMLIY ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101