描述

一、产品定位与核心价值

中端励磁控制板定位:

UNS0868B-P是UNITROL 6000系列的经济型(ECO)版本,适用于额定功率1MW-50MW的同步发电机,满足中小型发电站对励磁控制精度、系统可靠性和成本效益的综合需求。

与上一代UNITROL 5000系列相比,UNS0868B-P的硬件集成度提升50%(单板集成CPU、测量、控制、通信模块),体积缩小30%(2U机架式vs 3U机架式),但核心功能(励磁控制、电压调节、保护逻辑)完全保留,且功耗降低20%(<40W vs<50W)。

与同系列UNS0871A-P(标准版)相比,UNS0868B-P取消了冗余CPU模块和部分高级通信接口(如Modbus TCP/IP),但关键测量通道(电压、电流)仍采用双冗余设计,确保高可靠性,同时成本降低约15%,适合预算有限的项目。

核心价值:

精准励磁控制:通过高精度测量和自适应控制算法,实现励磁电流的快速、稳定调节,确保发电机端电压稳定在额定值(±0.5%UN),减少电压波动对电网和用电设备的影响。

增强系统可靠性:采用双通道冗余设计(测量、控制、通信),支持无扰切换(<10ms),避免单点故障导致的励磁失控;内置自诊断功能,可实时监测硬件状态、传感器信号、通信链路,提前预警潜在故障。

降低运维成本:支持远程参数配置和故障记录下载,减少现场调试时间;模块化设计允许在线更换故障部件(如电源模块、I/O板),缩短停机时间。

二、核心功能与特性

1.励磁控制能力

励磁方式支持:

自并励(SE):通过可控硅整流桥将发电机端电压转换为直流励磁电流,适用于水轮发电机、柴油发电机等低转速机组。

他励(AE):通过外部直流电源(如电池组、整流变压器)提供励磁电流,适用于汽轮发电机等高转速机组或需要独立励磁的场景。

励磁电流调节:

测量精度:采用16位A/D转换器,采样频率10kHz,可精确测量励磁电压(0-500V)和励磁电流(0-2000A),测量误差<±0.2%FS。

控制算法:内置自适应PID算法,可根据发电机负载变化自动调整比例(P)、积分(I)、微分(D)参数,确保励磁电流稳定(动态响应时间<30ms,超调量<1.5%)。

最小励磁限制:支持设定最小励磁电流(如10%IN),防止发电机失磁,保护转子绕组。

2.电压调节与保护功能

电压调节:

测量通道:支持双冗余电压测量(主/备通道独立采样),测量范围0-150%UN,测量精度<±0.1%FS。

调节模式:支持恒电压调节(AVR)、恒功率因数调节(PFR)和恒无功功率调节(QFR),可根据电网需求灵活切换。

动态响应:在负载突变(如50%额定负载跳变)时,电压恢复时间<100ms,超调量<2%。

保护功能:

过励磁保护:当励磁电流超过设定值(如120%IN)持续10s时,自动降低励磁电流并触发报警;若持续30s,则跳闸停机。

欠励磁保护:当励磁电流低于设定值(如8%IN)时,自动增加励磁电流并触发报警;若持续5s,则跳闸停机。

PT断线保护:当电压互感器(PT)断线时,自动切换至备用PT或闭锁电压调节功能,防止误调节。

3.通信与接口

标准接口:

模拟量输入:4路0-10V/4-20mA输入,用于外部信号接入(如功率因数设定值、无功功率设定值)。

模拟量输出:2路0-10V/4-20mA输出,用于励磁电流/电压监测或连接外部仪表。

数字量输入:8路干接点输入,用于启动/停止信号、保护复位、模式切换等。

数字量输出:4路继电器输出,用于报警信号、跳闸信号等。

通信协议:

Modbus RTU:通过RS485接口实现与上位机(如DCS、SCADA)的通信,支持参数读取、控制指令下发、故障记录上传。

IEC 61850(可选):支持GOOSE、MMS协议,适用于智能变电站或需要高速通信的场景。

1.Product Positioning and Core Value

Mid-end excitation control board positioning:

UNS0868B-P is the economical(ECO)version of the UNITROL 6000 series,suitable for synchronous generators with a rated power of 1MW-50MW,meeting the comprehensive needs of excitation control accuracy,system reliability and cost-effectiveness for small and medium-sized power plants.

Compared with the previous generation UNITROL 5000 series,the hardware integration of the UNS0868B-P is 50%higher(single-board integrated CPU,measurement,control,and communication modules),and the volume is reduced by 30%(2U rack vs 3U rack),but the core functions(excitation control,voltage regulation,protection logic)are completely retained and power consumption is reduced by 20%(<40W vs<50W).

Compared with the same series UNS0871A-P(standard version),UNS0868B-P eliminates redundant CPU modules and some advanced communication interfaces(such as Modbus TCP/IP),but the critical measurement channels(voltage,current)still adopt a dual redundant design to ensure high reliability while reducing costs by about 15%,making it suitable for projects with limited budgets.

Core Values:

Precise excitation control:Through high-precision measurement and adaptive control algorithms,the excitation current is achieved quickly and stably adjusted,ensuring that the generator terminal voltage is stable at the rated value(±0.5%UN),and reducing the impact of voltage fluctuations on the power grid and power consumption equipment.

Enhanced system reliability:adopts a dual-channel redundant design(measurement,control,communication),supports interference-free switching(<10ms),avoiding excitation loss caused by single point of failure;built-in self-diagnosis function,which can monitor hardware status,sensor signals,and communication links in real time,and warning of potential faults in advance.

Reduce operation and maintenance costs:Support remote parameter configuration and fault record download,reducing on-site debugging time;modular design allows online replacement of faulty components(such as power modules,I/O boards)to shorten downtime.

2.Core functions and characteristics

1.Excitation control capability

Excitation mode supports:

Self-convex excitation(SE):converts the generator terminal voltage into DC excitation current through a thyristor rectifier bridge,suitable for low-speed units such as water turbine generators and diesel generators.

Excitation(AE):Provides excitation current through an external DC power supply(such as battery packs,rectifier transformers),suitable for high-speed units such as steam turbine generators or scenarios where independent excitation is required.

Excitation current regulation:

Measurement accuracy:Using a 16-bit A/D converter,sampling frequency of 10kHz,can accurately measure excitation voltage(0-500V)and excitation current(0-2000A),and the measurement error is<±0.2%FS.

Control algorithm:Built-in adaptive PID algorithm,which can automatically adjust the proportion(P),integral(I),and differential(D)parameters according to the generator load change to ensure the stability of the excitation current(dynamic response time<30ms,overshoot<1.5%).

Minimum excitation limit:Support Setting the minimum excitation current(such as 10%IN)to prevent generator demagnetization and protect rotor windings.

2.Voltage regulation and protection functions

Voltage regulation:

Measurement channel:Supports dual redundant voltage measurement(main/solder channel independent sampling),measuring range 0-150%UN,measurement accuracy<±0.1%FS.

Adjustment mode:Supports constant voltage regulation(AVR),constant power factor regulation(PFR)and constant reactive power regulation(QFR),which can be flexibly switched according to grid requirements.

Dynamic response:When load suddenly changes(such as 50%rated load jump),the voltage recovery time is<100ms and the overshoot is<2%.

Protection function:

Overexcitation protection:When the excitation current exceeds the set value(such as 120%IN)for 10 seconds,the excitation current will be automatically reduced and the alarm will be triggered;if it lasts for 30 seconds,the trip will be stopped.

Underexcitation protection:When the excitation current is lower than the set value(such as 8%IN),the excitation current is automatically increased and the alarm is triggered;if it lasts for 5 seconds,the trip will be stopped.

PT disconnection protection:When the voltage transformer(PT)is disconnected,it automatically switches to the backup PT or lock-off voltage regulation function to prevent incorrect adjustment.

3.Communication and Interface

Standard interface:

Analog input:4 0-10V/4-20mA inputs,used for external signal access(such as power factor setting value,reactive power setting value).

Analog output:2 channels 0-10V/4-20mA outputs,used for excitation current/voltage monitoring or connecting to external instruments.

Digital input:8-channel dry contact input,used for start/stop signal,protection reset,mode switching,etc.

Digital output:4-channel relay output,used for alarm signals,tripping signals,etc.

Communication protocol:

Modbus RTU:Communication with the host computer(such as DCS,SCADA)is realized through the RS485 interface,and supports parameter reading,control command issuance,and fault record upload.

IEC 61850(optional):supports GOOSE and MMS protocols,suitable for smart substations or scenarios where high-speed communication is required.

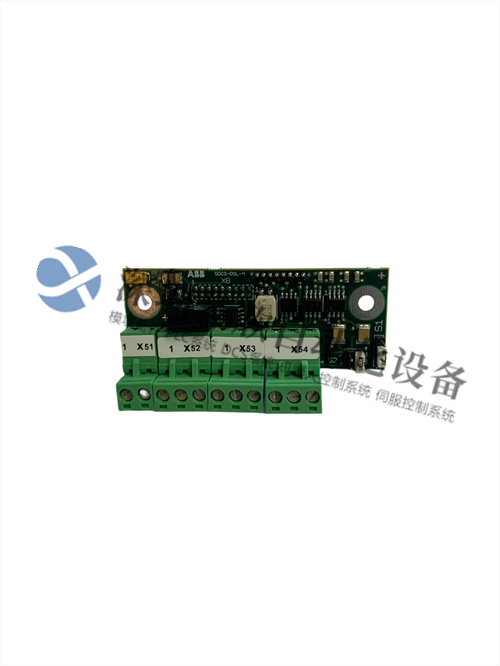

ABB 型号:GBU72 3BHE055094R0002 型号:3BHE055094R0002 GBU72 型号:GBU72 型号:3BHE055094R0002 型号:3BHE031197R0001 型号:3BHB030310R0001 型号:73BHE055094R0002 GBU72 型号:73BHE055094R0002 型号:GBU72 型号:ABB PCS6000 PRODUCT FAMLIY