描述

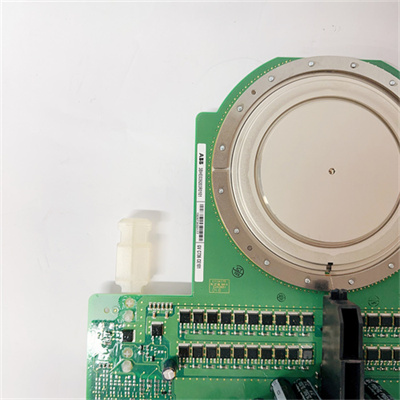

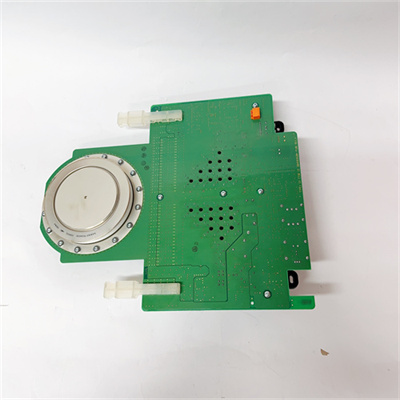

ABB 5SHY4045L0004是一款高性能半导体模块,基于集成门极换流晶闸管(IGCT)技术设计,广泛应用于中高压电力转换和工业控制领域。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术特点

IGCT技术优势

-高开关性能:结合晶闸管的高阻断电压和晶体管的快速可控开关特性,实现微秒级(μs)高速切换,无需复杂缓冲电路,降低系统复杂度。

-低导通损耗:优化的半导体结构显著降低导通压降,提升效率并减少热损耗,适用于高功率密度场景。

高功率与可靠性

-电压与电流能力:支持中压应用(最高6.5 kV),额定电流可达数千安培,适用于工业驱动、牵引系统等重载场景。

-温度适应性:1700 V SPT++芯片组可耐受175°C高温,提升模块设计灵活性和功率密度。

保护与控制集成

-内置保护功能:集成过流、短路保护及温度监测,支持快速故障恢复,保障系统安全运行。

-LinPak并联技术:通过简单扩展即可提升逆变器额定电流,简化供应链与设备设计。

模块化与兼容性

-标准化接口:支持Profibus DP、EtherCAT等工业总线协议,可无缝集成至自动化系统。

-扩展性:适用于电压源逆变器(VSI)、电流源逆变器(CSI)及主动前端(AFE)等拓扑结构。

二、典型应用场景

工业驱动与牵引系统

-高速铁路牵引变流器、矿山机械驱动、港口起重机等重载设备。

-支持再生制动与能量回收,提升能源效率。

可再生能源

-风力涡轮机变流器、光伏逆变器及储能系统,满足可再生能源并网需求。

-优化电网稳定性,降低谐波干扰。

电力系统

-柔性交流输电(FACTS)、静止无功补偿(SVG)及直流输电(HVDC)系统。

-增强电网动态响应能力。

自动化控制

-替代传统继电器电路,实现逻辑控制、顺序控制及多机群控,适用于化工、冶金等流程工业。

ABB 5SHY4045L0004 is a high-performance semiconductor module designed based on integrated gate-commutated thyristor(IGCT)technology and widely used in medium and high voltage power conversion and industrial control.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical features

IGCT technology advantages

-High switching performance:Combining the high blocking voltage of thyristors and the fast controllable switching characteristics of transistors,high-speed switching in microseconds(μs)is achieved,without complex buffer circuits,reducing system complexity.

-Low conduction loss:The optimized semiconductor structure significantly reduces the conduction voltage drop,improves efficiency and reduces heat loss,and is suitable for high power density scenarios.

High power and reliability

-Voltage and current capabilities:Supports medium voltage applications(up to 6.5 kV)and rated currents of up to thousands of amperes,suitable for heavy-duty scenarios such as industrial drives and traction systems.

-Temperature adaptability:The 1700 V SPT++chipset can withstand high temperatures of 175°C,improving module design flexibility and power density.

Protection and control integration

-Built-in protection function:integrated overcurrent,short-circuit protection and temperature monitoring,support fast fault recovery,and ensure safe operation of the system.

-LinPak parallel technology:the rated current of the inverter can be increased through simple expansion,simplifying the supply chain and equipment design.

Modularity and compatibility

-Standardized interface:supports industrial bus protocols such as Profibus DP and EtherCAT,and can be seamlessly integrated into the automation system.

-Scalability:suitable for topologies such as voltage source inverter(VSI),current source inverter(CSI)and active front end(AFE).

2.Typical application scenarios

Industrial drive and traction system

-High-speed railway traction converter,mining machinery drive,port crane and other heavy-duty equipment.

-Support regenerative braking and energy recovery to improve energy efficiency.

Renewable energy

-Wind turbine converter,photovoltaic inverter and energy storage system to meet the needs of renewable energy grid connection.

-Optimize grid stability and reduce harmonic interference.

Power system

-Flexible AC transmission(FACTS),static VAR compensation(SVG)and high voltage direct current(HVDC)systems.

-Enhance the dynamic response capability of the power grid.

Automation control

-Replace traditional relay circuits to achieve logic control,sequence control and multi-machine group control,suitable for process industries such as chemical industry and metallurgy.