描述

ABB AOFC-02是一款高性能电源模块,专为工业自动化系统设计,具备强大的运算与控制能力,广泛应用于环保、地矿、建材、电子及电气等领域。以下是其核心功能与技术参数的综合概述:

一、产品概述

类型:电源模块

应用领域:化工、矿业、建材、电子设备及电气系统

核心功能:为可编程逻辑控制器(PLC)提供稳定电源支持,支持逻辑运算、计时计数及复杂控制功能

二、运算功能

基础运算

-逻辑运算(如与、或、非等)

-计时和计数功能

扩展运算

-数据移位、比较等普通PLC功能

-代数运算、数据传送等较复杂功能

-模拟量PID运算、数值转换等高级功能(适用于大型PLC)

通信功能

-支持与下位机、上位机或工厂网络的数据通信

-兼容开放系统协议,提升系统集成性

三、控制功能

常规控制

-顺序逻辑控制(适用于大多数工业场景)

-单回路或多回路PID控制

高级控制

-前馈补偿控制

-比值控制

-高速计数器与模拟量补偿功能(如带速度补偿的模拟单元)

四、处理性能

扫描速度

-小型PLC:≤0.5ms/K

-大中型PLC:≤0.2ms/K

-处理速度受用户程序长度及CPU性能影响

响应时间

-每条二进制指令执行时间:0.2~0.4μs

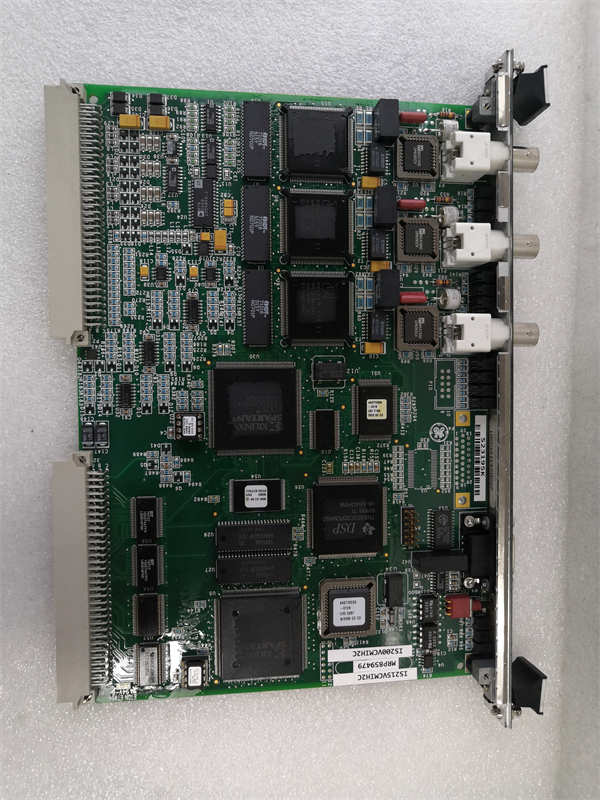

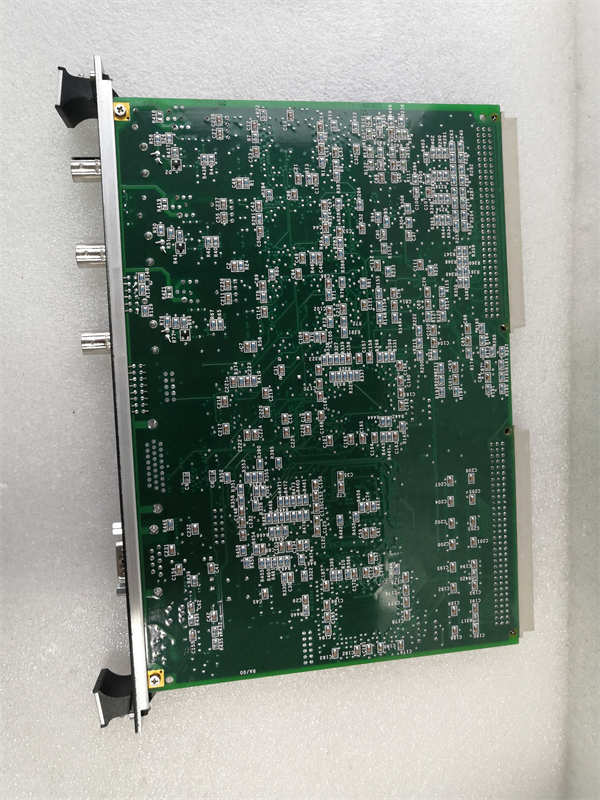

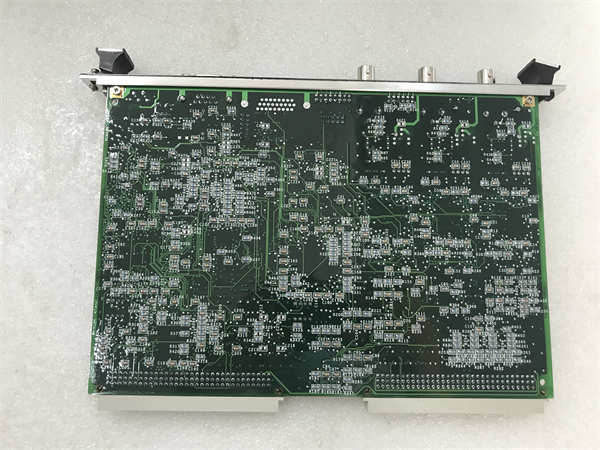

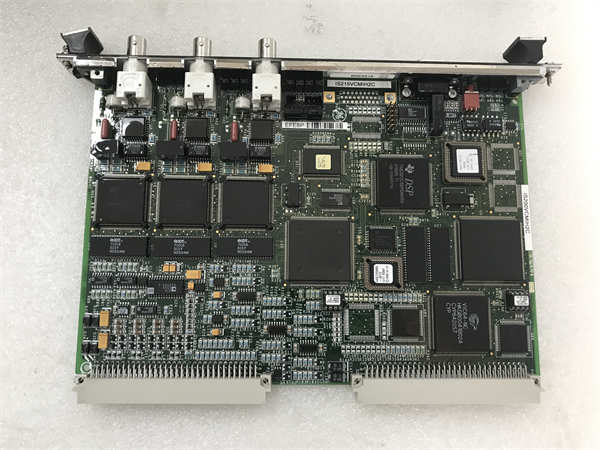

IS230STAOH2A

IS230STAOH2A

-能满足高实时性控制需求.ABB AOFC-02 is a high-performance power module designed for industrial automation systems.It has powerful computing and control capabilities and is widely used in environmental protection,mining,building materials,electronics and electrical fields.The following is a comprehensive overview of its core functions and technical parameters:

I.Product Overview

Type:Power Module

Application Areas:Chemical,Mining,Building Materials,Electronic Equipment and Electrical Systems

Core Function:Provide stable power supply support for programmable logic controllers(PLCs),support logical operations,timing counting and complex control functions

II.Operation Function

Basic Operation

-Logical Operation(such as AND,OR,NOT,etc.)

-Timing and Counting Function

Extended Operation

-Common PLC functions such as data shifting and comparison

-More complex functions such as algebraic operations and data transmission

-Advanced functions such as analog PID operations and numerical conversion(applicable to large PLCs)

Communication Function

-Support data communication with the lower computer,upper computer or factory network

-Compatible with open system protocols to improve system integration

III.Control Function

Conventional Control

-Sequential Logic Control(applicable to most industrial scenarios)

-Single-loop or multi-loop PID control

Advanced Control

-Feedforward Compensation Control

-Ratio Control

-High-speed Counter and Analog Compensation Function(such as analog unit with speed compensation)

IV.Processing Performance

Scanning Speed

-Small PLC:≤0.5ms/K

-Medium and large PLC:≤0.2ms/K

-Processing speed is affected by user program length and CPU performance

Response time

-Execution time of each binary instruction:0.2~0.4μs

-Can meet high real-time control requirements