描述

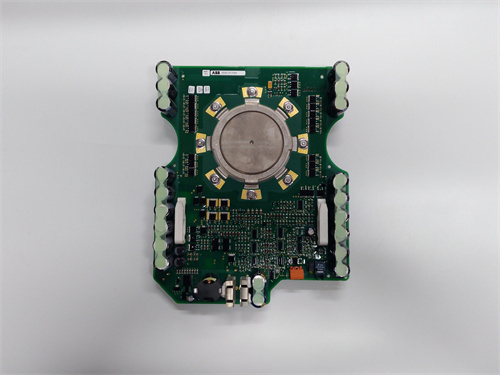

ABB ARCOL 0346是一款高性能可编程逻辑控制器(PLC)模块,专为工业自动化和复杂控制系统设计,具备灵活的内存管理、高处理能力及多协议兼容性。以下是其核心功能与技术特点的综合概述:

一、技术特点

内存管理机制

-采用描述字地址修改技术,主存地址仅通过描述字修改,数组元素通过地址偏移量访问,支持向量描述字的硬件自动换算,简化了内存操作流程。

-支持连续存储的数组结构,适用于批量数据处理场景。

处理性能

-工作电压:220V AC;

-处理速度:15Hz(逻辑处理能力);

-存储容量:程序存储2MB,数据存储1MB,满足复杂控制逻辑需求。

兼容性与扩展性

-支持多协议通信(如Modbus、PROFINET),可与ABB Panel 800系列HMI面板无缝对接;

-兼容其他品牌控制器(如施耐德、通用电气等),适配开放架构的工业系统。

二、核心功能

逻辑控制与编程

-支持LD指令处理器,通过硬PLC实现快速逻辑运算;

-集成模板和库文件,缩短工程设计周期。

人机交互

-支持TFT/LED高分辨率显示,提供基于图标的导航界面;

-Panel Builder工具支持Microsoft Windows环境,实现多语言工程设计。

工业级可靠性

-防护等级IP20,工作温度范围-30℃~+70℃,湿度95%;

-通过UL认证,适用于潮湿、多尘等严苛环境。

三、应用场景

工业自动化

-机械臂运动控制、流水线逻辑分拣、机器人协作系统。

过程控制

-化工反应流程监控、环保设备数据采集、电力系统故障诊断。

设备监测

-电梯运行状态分析、风机启停逻辑控制、水处理系统流量监测。

四、优势总结

灵活性:模块化设计支持热插拔,方便系统扩展与维护;

高效性:处理速度达15Hz,满足实时控制需求;

兼容性:基于.NET框架的开放架构,支持多品牌系统集成。

ABB ARCOL 0346 is a high-performance programmable logic controller(PLC)module designed for industrial automation and complex control systems.It has flexible memory management,high processing power and multi-protocol compatibility.The following is a comprehensive overview of its core functions and technical features:

I.Technical Features

Memory Management Mechanism

-Using the description word address modification technology,the main memory address is only modified by the description word,and the array elements are accessed by the address offset.It supports the hardware automatic conversion of vector description words,which simplifies the memory operation process.

-Supports continuous storage array structure,suitable for batch data processing scenarios.

Processing Performance

-Working voltage:220V AC;

-Processing speed:15Hz(logical processing capability);

-Storage capacity:2MB for program storage and 1MB for data storage,meeting the needs of complex control logic.

Compatibility and Scalability

-Supports multi-protocol communication(such as Modbus,PROFINET),and can be seamlessly connected with ABB Panel 800 series HMI panels;

-Compatible with other brands of controllers(such as Schneider,General Electric,etc.),and adapts to open architecture industrial systems.

2.Core functions

Logic control and programming

-Support LD instruction processor,realize fast logic operation through hard PLC;

-Integrate templates and library files to shorten the engineering design cycle.

Human-computer interaction

-Support TFT/LED high-resolution display,provide icon-based navigation interface;

-Panel Builder tool supports Microsoft Windows environment,realize multi-language engineering design.

Industrial reliability

-Protection level IP20,operating temperature range-30℃~+70℃,humidity 95%;

-UL certified,suitable for harsh environments such as humid and dusty.

3.Application scenarios

Industrial automation

-Robot arm motion control,assembly line logic sorting,robot collaboration system.

Process control

-Chemical reaction process monitoring,environmental protection equipment data collection,power system fault diagnosis.

Equipment monitoring

-Elevator operation status analysis,fan start and stop logic control,water treatment system flow monitoring.

IV.Advantages Summary

Flexibility:The modular design supports hot-swap,facilitating system expansion and maintenance;

Efficiency:The processing speed reaches 15Hz,meeting the real-time control requirements;

Compatibility:The open architecture based on the.NET framework supports multi-brand system integration.