描述

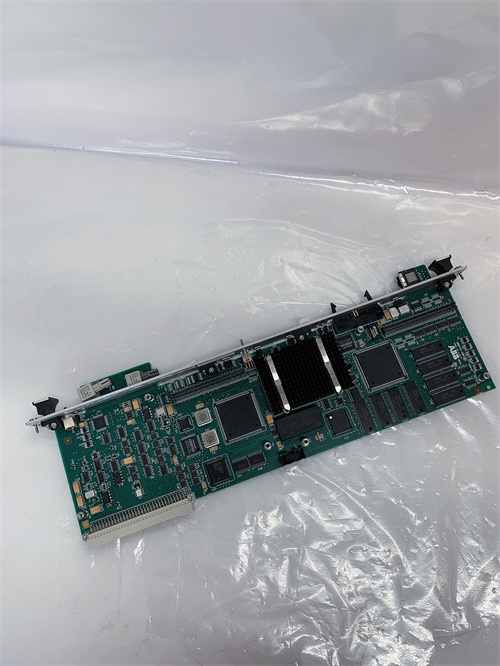

ABB MPRC086444-005是一款多功能工业自动化模块,集数字量输入、模拟量测量与通信功能于一体,广泛应用于工业控制、过程监控及自动化系统中。以下是其核心产品特性与技术参数的综合概述:

一、核心功能与技术特性

数字量输入与信号处理

-支持多个数字量输入通道(最高可达16通道),可连接开关、传感器等设备,实时采集状态信号。

-具备状态变化检测功能,可触发控制操作(如高电平到低电平切换)。

-部分型号支持高速采样(适用于高速机器控制)。

模拟量测量与调理

-支持电压、电流、温度等信号类型,具备滤波、放大及转换功能,确保数据精度。

-支持多种测量协议,适用于工业现场的复杂信号环境。

通信与集成能力

-支持Modbus TCP、ProfiNet、EtherCAT、EtherNet/IP、CC-Link等工业协议,可无缝对接PLC、DCS等控制系统。

-配备以太网、RS-232/RS-485等接口,实现数据透明传输。

模块化与扩展性

-支持1个通讯板和4个IO插槽扩展,用户可根据需求自由组合模拟/数字通道。

-模块化设计便于维护与升级,适用于复杂系统架构。

工业级可靠性与环境适应性

-防护等级IP65,采用ABS阻燃塑料外壳,耐高温(-20℃至40℃)、高湿及腐蚀性环境。

-内置过载保护与短路保护,确保系统稳定性。

二、典型应用领域

工业自动化

-生产线设备监测、机器人控制及数据采集。

过程控制

-化工、冶金行业中的液位、温度、压力参数监控。

电力系统

-开关状态检测、电流/电压实时采集。

环境监测

-气体浓度、湿度等参数的长期稳定监测。

交通与安全

-交通信号灯控制、设备健康诊断及安全冗余系统。

三、技术参数与规格

电源:220 V AC,50 Hz,500 W

通道数:单模块最大支持16通道(模拟+数字混合)

通信协议:Modbus TCP、ProfiNet、EtherCAT等

防护等级:IP65

工作温度:-20℃至40℃

显示与维护:LCD屏可实时查看通道状态、通信参数及模块版本信息。

四、设计优势

人性化交互

-LCD显示界面支持参数调试与状态监控,简化维护流程。

安全性

-支持输入信号冗余验证,防止误操作导致系统故障。

经济性

-模块化设计降低扩展成本,适配不同规模系统需求。

ABB MPRC086444-005 is a multifunctional industrial automation module that integrates digital input,analog measurement and communication functions.It is widely used in industrial control,process monitoring and automation systems.The following is a comprehensive overview of its core product features and technical parameters:

I.Core functions and technical features

Digital input and signal processing

-Supports multiple digital input channels(up to 16 channels),can connect switches,sensors and other devices,and collect status signals in real time.

-Has state change detection function,which can trigger control operations(such as high-level to low-level switching).

-Some models support high-speed sampling(suitable for high-speed machine control).

Analog measurement and conditioning

-Supports signal types such as voltage,current,temperature,etc.,and has filtering,amplification and conversion functions to ensure data accuracy.

-Supports multiple measurement protocols,suitable for complex signal environments in industrial sites.

Communication and integration capabilities

-Supports industrial protocols such as Modbus TCP,ProfiNet,EtherCAT,EtherNet/IP,CC-Link,etc.,and can seamlessly connect to control systems such as PLC and DCS.

-Equipped with Ethernet,RS-232/RS-485 and other interfaces to achieve transparent data transmission.

Modularity and scalability

-Supports 1 communication board and 4 IO slot expansions,and users can freely combine analog/digital channels according to their needs.

-Modular design facilitates maintenance and upgrades,and is suitable for complex system architectures.

Industrial-grade reliability and environmental adaptability

-Protection level IP65,using ABS flame-retardant plastic shell,resistant to high temperature(-20℃to 40℃),high humidity and corrosive environment.

-Built-in overload protection and short-circuit protection to ensure system stability.

2.Typical application areas

Industrial automation

-Production line equipment monitoring,robot control and data acquisition.

Process control

-Liquid level,temperature and pressure parameter monitoring in the chemical and metallurgical industries.

Power system

-Switch state detection,real-time current/voltage acquisition.

Environmental monitoring

-Long-term stable monitoring of parameters such as gas concentration and humidity.

Traffic and safety

-Traffic light control,equipment health diagnosis and safety redundancy system.

III.Technical parameters and specifications

Power supply:220 V AC,50 Hz,500 W

Number of channels:Single module supports up to 16 channels(analog+digital hybrid)

Communication protocol:Modbus TCP,ProfiNet,EtherCAT,etc.

Protection level:IP65

Operating temperature:-20℃to 40℃

Display and maintenance:LCD screen can view channel status,communication parameters and module version information in real time.

IV.Design advantages

Humanized interaction

-LCD display interface supports parameter debugging and status monitoring,simplifying the maintenance process.

Safety

-Supports input signal redundancy verification to prevent system failure caused by misoperation.

Economical

-Modular design reduces expansion costs and adapts to system requirements of different scales.