描述

ABBR1.CAIR是一款高性能气体检测与控制模块,专为工业自动化和安全监测设计,适用于高精度气体分析、环境控制及危险场景防护。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术特点

气体检测与分析

支持多种气体类型(如CO₂、O₂、有毒气体等)的实时监测,检测范围广、精度高(±1%FS),响应时间≤2秒,适用于化工、制药、能源等行业的气体泄漏预警与过程控制。

数据采集与控制

-集成模拟量输出(4-20mA)、数字量I/O及通信接口,支持远程数据上传与本地控制逻辑编程。

-支持PID算法优化,可实现闭环控制(如通风系统联动、报警阈值动态调整)。

通信与协议兼容性

-接口类型:双以太网端口(支持Modbus TCP、Profinet)、RS485(Modbus RTU)。

-扩展能力:可接入ABB AC 800M控制系统,兼容OPC UA、MQTT等工业物联网协议。

二、环境适应性与防护设计

防护等级:IP65,防尘防水,抗电磁干扰(符合IEC 60068标准)。

宽温工作:-40°C至70°C,支持极端环境下的连续运行。

抗振动设计:通过振动测试(IEC 60068-2-6),适用于工业现场复杂工况。

三、安全与认证

安全标准:符合ATEX防爆认证(II 2G Ex d IIB T4),适用于爆炸性气体环境。

防护机制:内置自检功能,检测传感器故障或信号异常时自动触发报警。

合规性:通过CE、UL认证,满足国际工业安全规范。

四、典型应用场景

石油化工

-监测储罐区可燃气体浓度,联动紧急切断阀与通风系统,预防爆炸风险。

-控制反应釜内氧气/惰性气体比例,确保工艺安全。

环境监测

-城市污水处理厂氨气、硫化氢浓度实时监控,优化生物处理工艺。

-工业园区空气质量网格化部署,生成热力图辅助环保监管。

医疗与食品

-医疗设备气体(如氧气、笑气)浓度监测,保障患者安全。

-食品加工车间氮气保护环境控制,防止氧化变质。

ABBR1.CAIR is a high-performance gas detection and control module designed for industrial automation and safety monitoring,suitable for high-precision gas analysis,environmental control and protection of hazardous scenarios.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical features

Gas detection and analysis

Supports real-time monitoring of multiple gas types(such as CO₂,O₂,toxic gases,etc.),with a wide detection range,high accuracy(±1%FS),and a response time of≤2 seconds.It is suitable for gas leak warning and process control in chemical,pharmaceutical,energy and other industries.

Data acquisition and control

-Integrated analog output(4-20mA),digital I/O and communication interface,support remote data upload and local control logic programming.

-Support PID algorithm optimization,which can realize closed-loop control(such as ventilation system linkage,dynamic adjustment of alarm threshold).

Communication and protocol compatibility

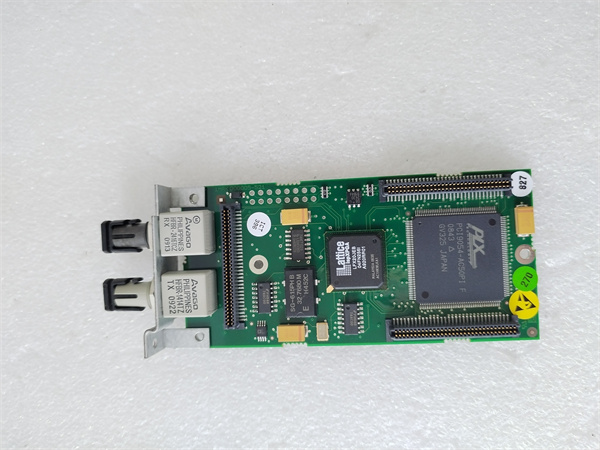

-Interface type:dual Ethernet port(support Modbus TCP,Profinet),RS485(Modbus RTU).

-Expansion capability:can be connected to ABB AC 800M control system,compatible with industrial IoT protocols such as OPC UA and MQTT.

2.Environmental adaptability and protection design

Protection level:IP65,dustproof and waterproof,anti-electromagnetic interference(in accordance with IEC 60068 standard).

Wide operating temperature:-40°C to 70°C,supporting continuous operation in extreme environments.

Anti-vibration design:passed the vibration test(IEC 60068-2-6),suitable for complex working conditions in industrial sites.

3.Safety and certification

Safety standards:in line with ATEX explosion-proof certification(II 2G Ex d IIB T4),suitable for explosive gas environments.

Protection mechanism:built-in self-test function,automatically triggering alarm when detecting sensor failure or signal abnormality.

Compliance:passed CE and UL certification,meeting international industrial safety regulations.

4.Typical application scenarios

Petrochemical

-Monitor the concentration of combustible gas in the tank area,link the emergency shut-off valve and ventilation system to prevent explosion risks.

-Control the oxygen/inert gas ratio in the reactor to ensure process safety.

Environmental Monitoring

-Real-time monitoring of ammonia and hydrogen sulfide concentrations in urban sewage treatment plants to optimize biological treatment processes.

-Grid deployment of air quality in industrial parks to generate heat maps to assist environmental protection supervision.

Medical and Food

-Monitoring of gas concentrations in medical equipment(such as oxygen and nitrous oxide)to ensure patient safety.

-Nitrogen protection environment control in food processing workshops to prevent oxidation and deterioration.