描述

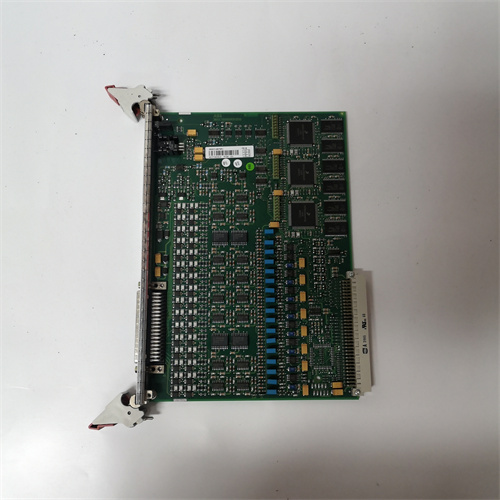

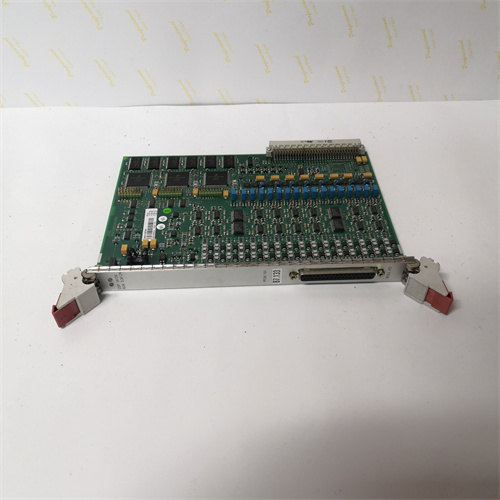

ABB R1091是一款功能强大的工业自动化模块,广泛应用于控制、数据采集与人机交互场景。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术特点

人机界面(HMI)集成

-配备TFT/LED高分辨率显示屏,支持多协议连接,适用于化工、电子等复杂环境下的实时监控与操作。

-提供PP886R、PP887H、PP887S等型号,内置模板和库,支持快速工程设计与图形化编程(如FBD、LD、ST等IEC1131-3标准语言)。

模块化与扩展性

-采用模块式结构,支持控制室安装,兼容DIN导轨(35mm)和金属底板固定,可通过通信模块扩展本地或远程访问功能。

-支持多品牌控制器连接,基于.NET框架的开放架构便于系统集成。

工业级可靠性

-压铸铝制外壳,防护等级IP65,适应-30℃~+70℃温度范围及95%湿度环境,适用于多尘、潮湿工况。

-支持程序与数据备份恢复,确保在线参数修改的安全性。

二、技术参数

处理能力:硬PLC架构,处理速度13Hz,程序容量2MB,数据容量1MB

电气特性:工作电压220V AC,输出频率35Hz

认证标准:UL认证

三、典型应用场景

化工与电子制造

-实时监控反应釜温度、压力参数,实现工艺流程自动化控制。

-电子设备生产线中的人机交互界面,支持远程故障诊断与维护。

能源与电力

-发电机保护系统中数据采集与报警显示,辅助运维决策。

-配电柜内模块化扩展,优化电力系统监控效率。

智能制造

-工业机器人操作界面集成,支持轨迹规划与参数调整。

-智能仓储系统中设备状态可视化监控。

ABB R1091 is a powerful industrial automation module,widely used in control,data acquisition and human-machine interaction scenarios.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical features

Human-machine interface(HMI)integration

-Equipped with TFT/LED high-resolution display,supports multi-protocol connection,suitable for real-time monitoring and operation in complex environments such as chemical and electronic industries.

-Provides models such as PP886R,PP887H,PP887S,built-in templates and libraries,support rapid engineering design and graphical programming(such as FBD,LD,ST and other IEC1131-3 standard languages).

Modularity and scalability

-Adopts a modular structure,supports control room installation,is compatible with DIN rails(35mm)and metal baseplate fixation,and can expand local or remote access functions through communication modules.

-Supports multi-brand controller connection,and the open architecture based on the.NET framework facilitates system integration.

Industrial-grade reliability

-Die-cast aluminum housing,protection level IP65,adapt to-30℃~+70℃temperature range and 95%humidity environment,suitable for dusty and humid working conditions.

-Support program and data backup and recovery to ensure the safety of online parameter modification.

2.Technical parameters

Processing capacity:hard PLC architecture,processing speed 13Hz,program capacity 2MB,data capacity 1MB

Electrical characteristics:working voltage 220V AC,output frequency 35Hz

Certification standard:UL certification

3.Typical application scenarios

Chemical and electronic manufacturing

-Real-time monitoring of reactor temperature and pressure parameters to achieve process automation control.

-Human-machine interaction interface in electronic equipment production line,supporting remote fault diagnosis and maintenance.

Energy and power

-Data collection and alarm display in generator protection system to assist operation and maintenance decision-making.

-Modular expansion in distribution cabinet to optimize power system monitoring efficiency.

Intelligent manufacturing

-Industrial robot operation interface integration,supporting trajectory planning and parameter adjustment.

-Visual monitoring of equipment status in intelligent warehousing systems.