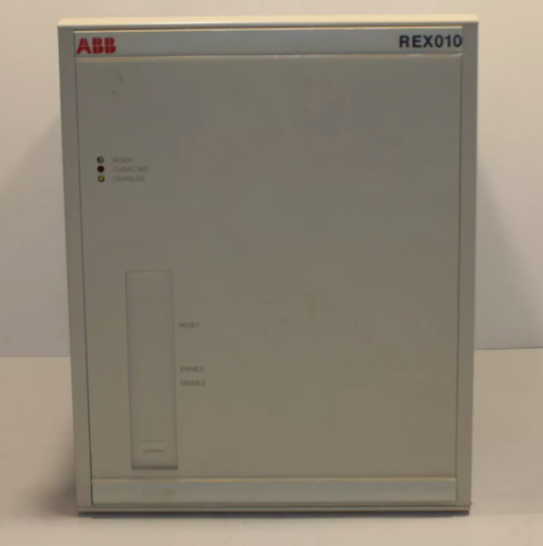

描述

ABB REX010是一款功能全面、技术先进的工业自动化模块,广泛应用于电力系统保护、数据采集与控制、安全联锁等领域。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术特点

接地故障保护装置

-高效保护能力:专为发电机侧接地故障设计,支持分段配置保护,覆盖定子和转子100%接地故障,适用于发电机静止、启动及运行状态。

-安全可靠性:通过高精度检测与快速响应,有效避免设备损坏及生产中断,符合国际安全标准(如CE认证)。

输入输出模块(I/O)

-模块化架构:采用积木式或笼式插板结构,支持灵活扩展数字/模拟输入输出通道,满足不同规模系统需求。

-高精度与低噪声:模拟输入模块(如HESG324426R0001)具备高精度数据转换(±0.1%~±0.5%)和低噪声特性,适用于压力、温度等工艺参数监测。

-通信接口:支持PXI总线、EtherCAT、Modbus等协议,兼容LabVIEW、NI-DAQmx等开发工具,便于系统集成。

智能控制与数据处理

-硬PLC处理器:集成LD指令处理器,程序容量16MB,数据容量500MB,支持高速扫描(0.9ms)与复杂逻辑运算。

-扩展功能:可通过通信模块实现与上位机、下位机数据交换,或通过D/A模块直接控制伺服系统,支持远程终端连接器扩展输入输出点。

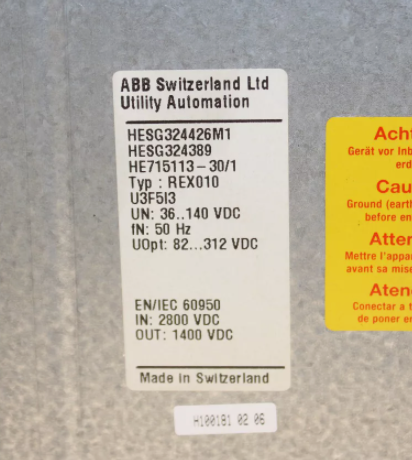

二、技术参数

工作电压:24V DC(I/O模块)、220V AC(保护装置)

环境适应性:

-温度:-40℃~+70℃(I/O模块)、0℃~+70℃(保护装置)

-湿度:5%~95%非凝结(I/O模块)

认证标准:CE、EU等国际认证

三、典型应用场景

电力与能源:

-发电机励磁系统保护、风电场电网电压波动抑制、变电站数据采集。

工业自动化:

-机器人I/O通信接口集成、CNC机床控制、安全联锁监控(如非接触式安全开关he系列)。

过程控制:

-化工装置压力/流量监测、制药设备安全防护、食品加工生产线控制。

预测性维护:

-通过数据采集与分析实现设备故障预警,优化维护周期。

ABB REX010 is a comprehensive and technologically advanced industrial automation module,which is widely used in power system protection,data acquisition and control,safety interlocking and other fields.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical features

Ground fault protection device

-Efficient protection capability:Designed for ground faults on the generator side,it supports segmented configuration protection,covers 100%ground faults on the stator and rotor,and is suitable for generator static,startup and running states.

-Safety and reliability:Through high-precision detection and rapid response,it effectively avoids equipment damage and production interruptions,and complies with international safety standards(such as CE certification).

Input and output module(I/O)

-Modular architecture:Adopting building block or cage plug-in structure,it supports flexible expansion of digital/analog input and output channels to meet the needs of systems of different scales.

-High precision and low noise:Analog input modules(such as HESG324426R0001)have high-precision data conversion(±0.1%~±0.5%)and low noise characteristics,which are suitable for monitoring process parameters such as pressure and temperature.

-Communication interface:supports PXI bus,EtherCAT,Modbus and other protocols,compatible with LabVIEW,NI-DAQmx and other development tools,easy to integrate the system.

Intelligent control and data processing

-Hard PLC processor:integrated LD instruction processor,program capacity 16MB,data capacity 500MB,support high-speed scanning(0.9ms)and complex logic operations.

-Extended function:data exchange with the host computer and the slave computer can be realized through the communication module,or the servo system can be directly controlled through the D/A module,and the remote terminal connector can be used to expand the input and output points.

2.Technical parameters

Working voltage:24V DC(I/O module),220V AC(protection device)

Environmental adaptability:

-Temperature:-40℃~+70℃(I/O module),0℃~+70℃(protection device)

-Humidity:5%~95%non-condensing(I/O module)

Certification standards:CE,EU and other international certifications

3.Typical application scenarios

Power and energy:

-Generator excitation system protection,wind farm grid voltage fluctuation suppression,substation data acquisition.

Industrial automation:

-Robot I/O communication interface integration,CNC machine tool control,safety interlock monitoring(such as non-contact safety switch he series).

Process control:

-Chemical plant pressure/flow monitoring,pharmaceutical equipment safety protection,food processing production line control.

Predictive maintenance:

-Equipment failure warning and maintenance cycle optimization through data collection and analysis.