描述

ABB RMIO-12C是一款专为工业自动化及机器人系统设计的高性能控制板,其核心功能与技术特点如下:

一、产品概述

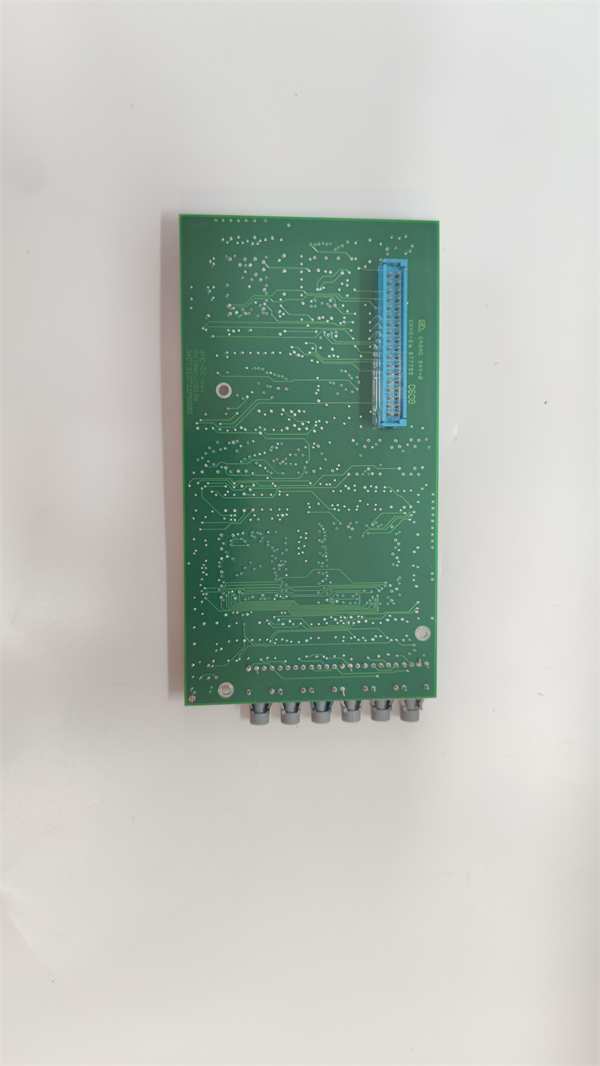

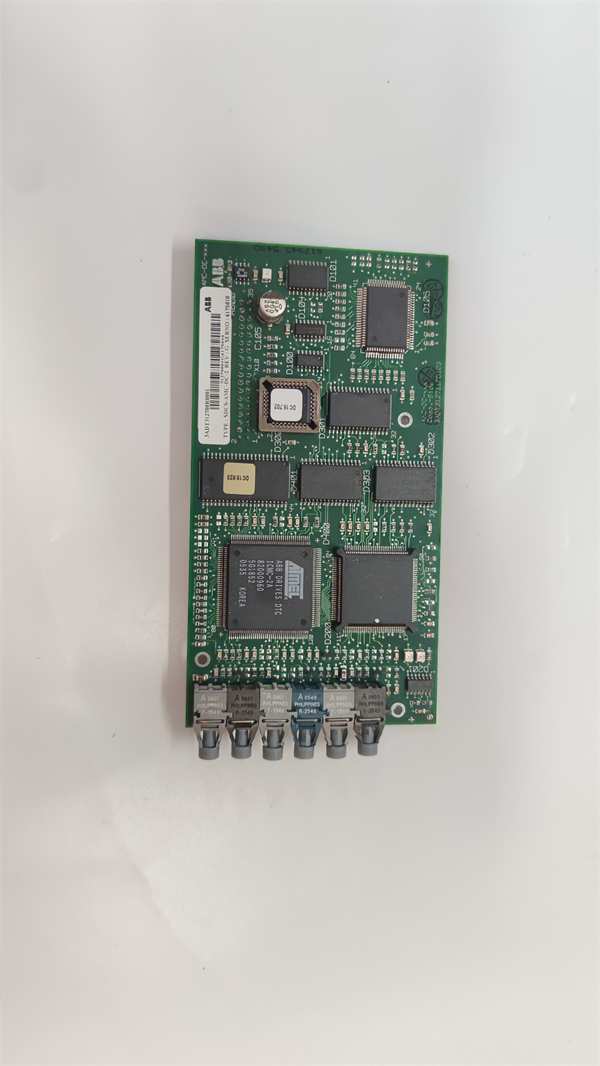

RMIO-12C控制板是ABB公司开发的电气控制设备,主要用于机器人系统的控制与监测,支持电机、发电机等设备的高效运行。其设计基于先进微处理器技术,具备高可靠性、稳定性及灵活扩展性。

二、技术参数

物理尺寸

-净重:0.18公斤

-尺寸:240毫米(宽)×100毫米(高)×10毫米(深)

环境适应性

-工作温度范围:-40℃~+70℃

-防护等级:IP65(部分型号)

三、核心功能

高效控制能力

-内置多种控制算法,支持定制化编程,可实现对机器人、电机等设备的精准控制。

-支持远程控制与监控,适用于工业自动化生产线及复杂控制系统。

通信与扩展性

-支持多种工业通信协议(如Modbus、CAN总线),方便与其他设备集成。

-可通过级联模块扩展功能,满足不同规模系统需求。

安全保护

-集成过压、欠压保护及温度监控功能,支持远程故障诊断与维护。

-防静电设计,符合工业环境防静电标准。

四、应用场景

机器人系统

-为工业机器人提供运动控制与轨迹规划,适用于焊接、装配等自动化任务。

电力与能源

-控制发电机、变压器等设备的运行状态,优化电力系统效率。

智能制造

-集成于智能工厂生产线,实现设备协同与数据采集分析。

RMU610 2VAA008425R1

RMU610 2VAA008425R1

ABB RMIO-12C is a high-performance control board designed for industrial automation and robotic systems.Its core functions and technical features are as follows:

I.Product Overview

RMIO-12C control board is an electrical control device developed by ABB,mainly used for the control and monitoring of robotic systems,supporting the efficient operation of motors,generators and other equipment.Its design is based on advanced microprocessor technology,with high reliability,stability and flexible scalability.

II.Technical Parameters

Physical Dimensions

-Net weight:0.18 kg

-Dimensions:240 mm(width)×100 mm(height)×10 mm(depth)

Environmental adaptability

-Operating temperature range:-40℃~+70℃

-Protection level:IP65(some models)

III.Core Functions

Efficient control capability

-Built-in multiple control algorithms,support customized programming,and can achieve precise control of robots,motors and other equipment.

-Support remote control and monitoring,suitable for industrial automation production lines and complex control systems.

Communication and scalability

-Supports multiple industrial communication protocols(such as Modbus,CAN bus),which is convenient for integration with other devices.

-Functions can be expanded through cascading modules to meet the needs of systems of different scales.

Safety protection

-Integrated overvoltage,undervoltage protection and temperature monitoring functions,supporting remote fault diagnosis and maintenance.

-Anti-static design,in line with the anti-static standards of industrial environments.

IV.Application scenarios

Robot system

-Provides motion control and trajectory planning for industrial robots,suitable for automation tasks such as welding and assembly.

Power and energy

-Control the operating status of equipment such as generators and transformers to optimize the efficiency of power systems.

Smart manufacturing

-Integrate into smart factory production lines to achieve equipment collaboration and data collection and analysis.