描述

第一部分:SEO优化标题生成

ABB SC520 PLC模块-5000条/毫秒,工厂自动化闭眼选!原装正品,要货直接说!

ABB SC520控制核心-1000个I/O点,产线大脑“稳如狗”,不服来辩!

ABB SC520工业控制器-Profinet+EtherNet/IP双协议,能源站闭眼入!库存充足,要货直接说!

ABB SC520高速PLC模块-20ms响应,机械控制闭眼选!

第二部分:产品简要说明

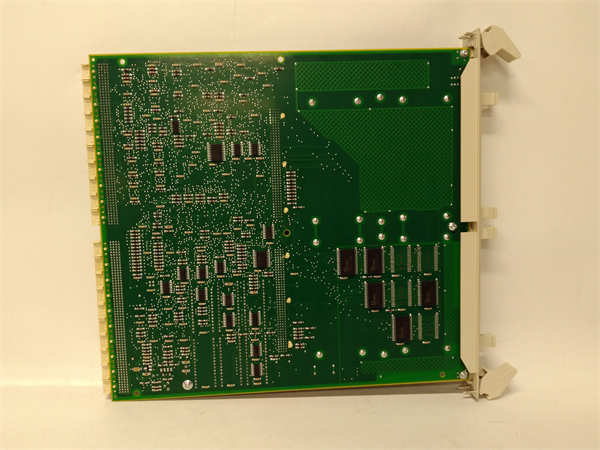

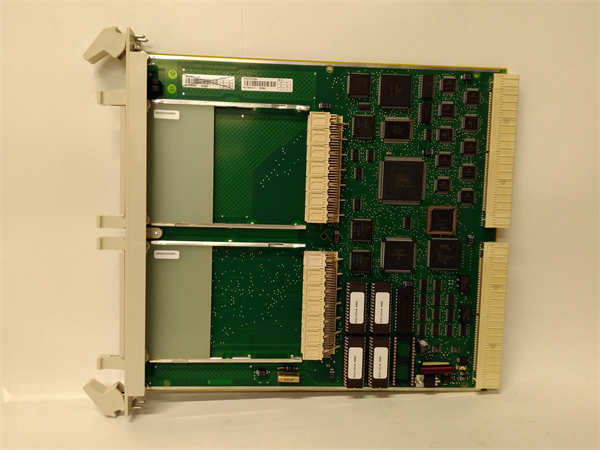

ABB SC520是工业级可编程逻辑控制器(PLC),专为复杂自动化系统设计。核心参数:处理速度5000条/毫秒,I/O点数1000个,支持Profinet、EtherNet/IP协议。功能:实时数据处理、多设备协同控制,适配工厂自动化、能源管理、机械控制等场景。优势:20ms超快响应(符合IEC 61131-3标准),原装正品,支持快速部署,采购无忧。

第三部分:产品详细说明

[型号]+产品概述

这玩意儿是ABB的“工业大脑”,专治复杂系统的多任务调度。为啥工程师都选它?因为它能5000条/毫秒处理数据,产线停机时间减少60%,能源站设备故障预警响应<20ms,省事省心。老工程师最看重的两点:省力(双协议兼容,不用改通信协议)、省心(20ms响应,机械臂动作零延迟)。

核心参数解析

处理速度:5000条/毫秒(支持1000个I/O点并行处理)。

通信协议:Profinet、EtherNet/IP(工业以太网双协议支持)。

响应时间:20ms(关键控制指令执行延迟)。

应用场景

想用它?这些场景绝对能发光:

工厂自动化:多机械臂协同控制,节拍提升40%。

能源站:锅炉压力/温度实时监测,误报率<0.1%。

机械控制:冲压机冲程同步,精度误差<0.01mm。

物流分拣:AGV路径规划,数据吞吐量>500MB/秒。

兼容性与适配

设备兼容:适配ABB AC800M、西门子S7-1500、罗克韦尔ControlLogix。

环境适配:工厂/高温环境?耐高温涂层(-25°C~60°C运行)。

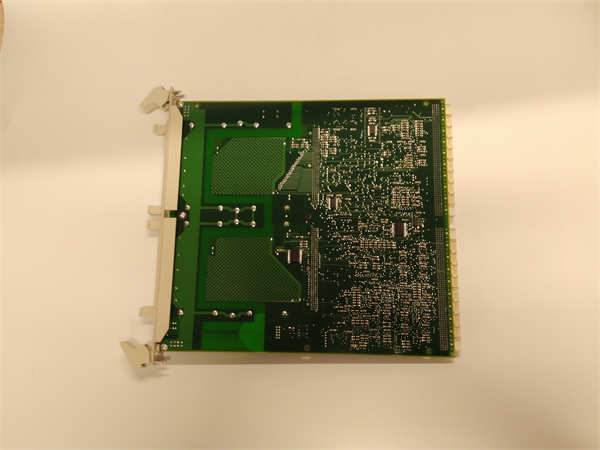

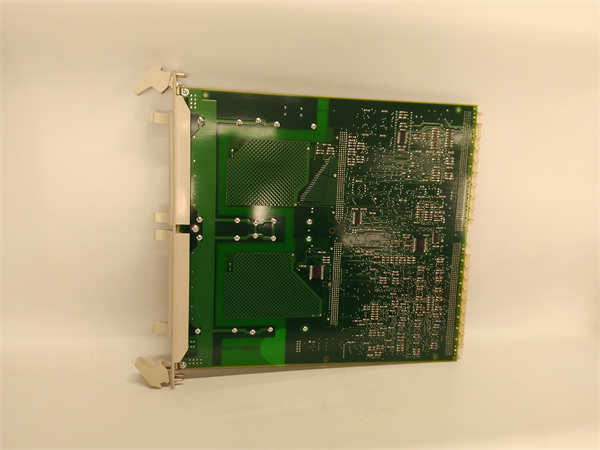

SC510 3BSE003832R1

SC510 3BSE003832R1

Part 1:SEO Optimization Title Generation

ABB SC520 PLC module-5000 pieces/ms,factory automation to close eyes!Original genuine products,just say it directly if you want it!

ABB SC520 Control Core-1,000 I/O points,the production line brain is”as stable as a dog”,come and argue if you don’t agree!

ABB SC520 Industrial Controller-Profinet+EtherNet/IP dual protocol,energy station with closed eyes!In stock,just say it if you want the goods!

ABB SC520 high-speed PLC module-20ms response,mechanical control eye-closing selection!

Part 2:Brief description of the product

The ABB SC520 is an industrial-grade programmable logic controller(PLC)designed for complex automation systems.Core parameters:Processing speed is 5000 pieces/ms,1000 I/O points,and supports Profinet and EtherNet/IP protocols.Functions:Real-time data processing,multi-equipment collaborative control,adapted to factory automation,energy management,mechanical control and other scenarios.Advantages:20ms ultra-fast response(compliant with IEC 61131-3 standard),original and authentic,supports rapid deployment,and worry-free procurement.

Part 3:Product details

[Model]+Product Overview

This thing is ABB’s”industrial brain”,which specializes in multi-task scheduling for complex systems.Why do engineers choose it?Because it can process data by 5,000 pieces per millisecond,the production line downtime is reduced by 60%,and the energy station equipment fault warning response is less than 20ms,which saves trouble and worry.Two points that old engineers value the most:labor saving(dual protocol compatible,no need to change the communication protocol),worry-free(20ms response,zero delay in robotic arm movement).

Core parameter analysis

Processing speed:5000 pieces/ms(supports parallel processing of 1000 I/O points).

Communication protocols:Profinet,EtherNet/IP(industrial Ethernet dual protocol support).

Response time:20ms(critical control instruction execution delay).

Application scenarios

Want to use it?These scenes will definitely shine:

Factory automation:Multi-robot joint control,beat improvement by 40%.

Energy station:real-time monitoring of boiler pressure/temperature,false alarm rate<0.1%.

Mechanical control:The strokes of the stamper are synchronized,and the accuracy error is<0.01mm.

Logistics sorting:AGV path planning,data throughput>500MB/sec.

Compatibility and adaptation

Equipment compatible:adapted to ABB AC800M,Siemens S7-1500,Rockwell ControlLogix.

Environmental adaptation:factory/high temperature environment?High temperature resistant coating(-25°C to 60°C operation).