描述

ABB SNAT634PAC是一款高性能工业自动化核心模块,兼具脉冲放大与运动控制功能,广泛应用于工业控制系统中。以下是其核心功能与技术特点的综合概述:

一、产品定位与核心功能

脉冲信号放大器

-专为放大微弱脉冲信号设计,将低幅度信号提升至足够强度,满足后续信号处理或执行机构需求,适用于高精度工业场景。

运动控制器

-集成先进控制算法与数字信号处理技术,可精确控制电机转速、转向及运动状态,支持不同负载特性与工作环境。

工业控制器模块

-支持多种通讯协议(如PROFINET、EtherNet/IP、Modbus TCP/IP、CANopen),具备安全PLC和安全IO功能,适用于复杂工业环境的高可靠性控制。

二、技术参数与性能

信号处理能力

-放大精度:高放大倍数,支持宽频率范围,低噪声设计,快速响应时间。

-接口配置:

-16个数字输入端口,8个数字输出端口;

-2个模拟输入端口,1个模拟输出端口;

-内置计时器、计数器及PID控制器。

环境适应性

-工作温度范围:-40°C至85°C;

-防护等级:未明确标注,但符合工业级可靠性要求。

三、功能特点

紧凑型设计

-体积小巧,便于集成到自动化设备中,适合空间受限场景。

智能化控制

-内置PID控制器,适用于温度、流量、压力等闭环控制;

-支持安全功能,如安全PLC与安全IO,保障工业生产安全性。

灵活性与兼容性

-支持多种通信协议,可无缝对接不同品牌设备;

-模块化结构,便于扩展与维护。

四、典型应用场景

工业机器人

-精确控制机器人关节运动,提升操作精度与效率。

数控机床与加工设备

-实现电机转速与定位控制,优化加工流程。

能源与电力系统

-控制交流发电机励磁系统,稳定电力输出。

包装与输送设备

-精确控制输送带速度及分拣逻辑,提高生产率。

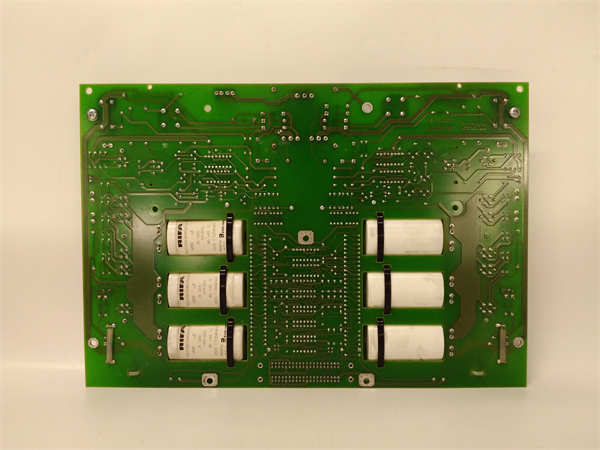

SNAT634PAC 61049452D

SNAT634PAC 61049452D

ABB SNAT634PAC is a high-performance industrial automation core module with both pulse amplification and motion control functions,and is widely used in industrial control systems.The following is a comprehensive overview of its core functions and technical features:

I.Product positioning and core functions

Pulse signal amplifier

-Designed to amplify weak pulse signals,it increases low-amplitude signals to sufficient strength to meet the needs of subsequent signal processing or actuators,and is suitable for high-precision industrial scenarios.

Motion controller

-Integrates advanced control algorithms and digital signal processing technology to accurately control motor speed,steering and motion state,and supports different load characteristics and working environments.

Industrial controller module

-Supports multiple communication protocols(such as PROFINET,EtherNet/IP,Modbus TCP/IP,CANopen),has safe PLC and safe IO functions,and is suitable for high-reliability control in complex industrial environments.

II.Technical parameters and performance

Signal processing capabilities

-Amplification accuracy:high amplification factor,support for wide frequency range,low noise design,and fast response time.

-Interface configuration:

-16 digital input ports,8 digital output ports;

-2 analog input ports,1 analog output port;

-Built-in timer,counter and PID controller.

Environmental adaptability

-Operating temperature range:-40°C to 85°C;

-Protection level:not clearly marked,but meets industrial reliability requirements.

III.Functional features

Compact design

-Small size,easy to integrate into automation equipment,suitable for space-constrained scenarios.

Intelligent control

-Built-in PID controller,suitable for closed-loop control of temperature,flow,pressure,etc.;

-Support safety functions such as safety PLC and safety IO to ensure industrial production safety.

Flexibility and compatibility

-Support multiple communication protocols,seamless connection with different brands of equipment;

-Modular structure,easy to expand and maintain.

IV.Typical application scenarios

Industrial robots

-Accurately control the movement of robot joints to improve operation accuracy and efficiency.

CNC machine tools and processing equipment

-Realize motor speed and positioning control to optimize processing processes.

Energy and power systems

-Control the AC generator excitation system to stabilize power output.

Packaging and conveying equipment

-Accurately control conveyor belt speed and sorting logic to improve productivity.