描述

ABB TPPB-02是一款专为工业机器人系统设计的核心控制模块,具备高精度运动控制、多轴协同及实时响应能力,适用于自动化生产、医疗、航空航天等场景。以下是其核心功能与技术特点的综合概述:

一、核心功能与技术特点

运动控制与多轴协同

-支持多关节机器人复杂运动控制,可独立调节多个轴的运动参数,实现精准定位与轨迹跟踪,适用于机械臂装配、焊接等高精度任务。

编程灵活性

-提供图形化编程工具及自定义语言接口,兼容主流工业协议(如Modbus、EtherCAT),支持用户根据需求快速开发控制逻辑。

安全性与实时性

-集成安全防护功能(如过载保护、碰撞检测),确保机器人运行安全;实时响应速度达毫秒级,满足高速生产节拍需求。

通信与扩展能力

-支持以太网、RS-485等通信协议,可无缝连接PLC、传感器及上位机系统,同时兼容模块化扩展接口(如I/O扩展模块)。

二、典型应用场景

工业制造

-汽车装配线、电子元件焊接等场景的机器人控制,提升生产效率与精度。

物流与仓储

-自动分拣机器人、AGV导航系统的核心控制单元,优化物料搬运流程。

医疗健康

-外科手术机器人、康复设备的运动控制模块,保障操作安全性与精准度。

航空航天

-无人飞行器姿态控制、太空机械臂操作等高可靠性场景。

三、设计优势

高防护等级:符合工业环境标准,抗电磁干扰能力强。

模块化架构:支持热插拔维护,便于系统升级与扩展。

能源效率:优化功耗设计,降低长期运行成本。

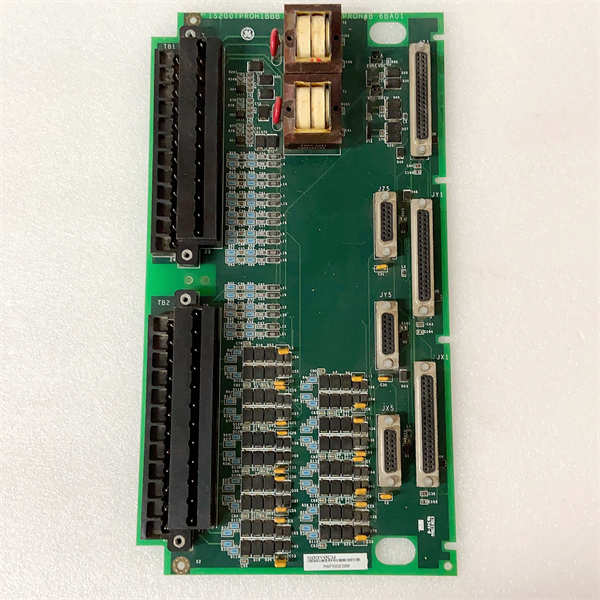

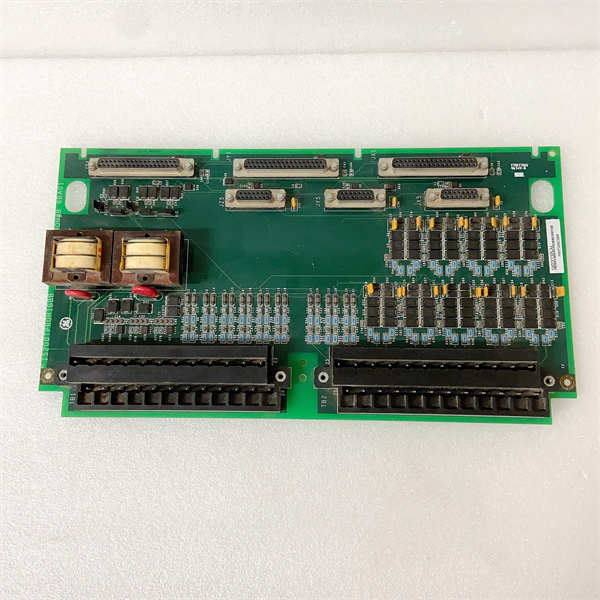

IS420ESWBH3AX

VME-PMC-CADD

ABB TPPB-02 is a core control module designed for industrial robot systems.It has high-precision motion control,multi-axis coordination and real-time response capabilities,and is suitable for automated production,medical,aerospace and other scenarios.The following is a comprehensive overview of its core functions and technical features:

I.Core functions and technical features

Motion control and multi-axis coordination

-Supports complex motion control of multi-joint robots,can independently adjust the motion parameters of multiple axes,achieve precise positioning and trajectory tracking,and is suitable for high-precision tasks such as robotic arm assembly and welding.

Programming flexibility

-Provides graphical programming tools and custom language interfaces,compatible with mainstream industrial protocols(such as Modbus,EtherCAT),and supports users to quickly develop control logic according to needs.

Safety and real-time

-Integrated safety protection functions(such as overload protection and collision detection)to ensure the safety of robot operation;real-time response speed reaches milliseconds to meet the needs of high-speed production rhythm.

Communication and expansion capabilities

-Supports communication protocols such as Ethernet and RS-485,can seamlessly connect PLC,sensors and host computer systems,and is compatible with modular expansion interfaces(such as I/O expansion modules).

2.Typical application scenarios

Industrial manufacturing

-Robot control in scenarios such as automobile assembly lines and electronic component welding to improve production efficiency and accuracy.

Logistics and warehousing

-The core control unit of automatic sorting robots and AGV navigation systems to optimize material handling processes.

Healthcare

-Motion control modules for surgical robots and rehabilitation equipment to ensure operational safety and accuracy.

Aerospace

-High reliability scenarios such as unmanned aerial vehicle attitude control and space robotic arm operation.

3.Design advantages

High protection level:meets industrial environment standards and has strong anti-electromagnetic interference capabilities.

Modular architecture:supports hot-swap maintenance,facilitating system upgrades and expansions.

Energy efficiency:optimizes power consumption design to reduce long-term operating costs.