描述

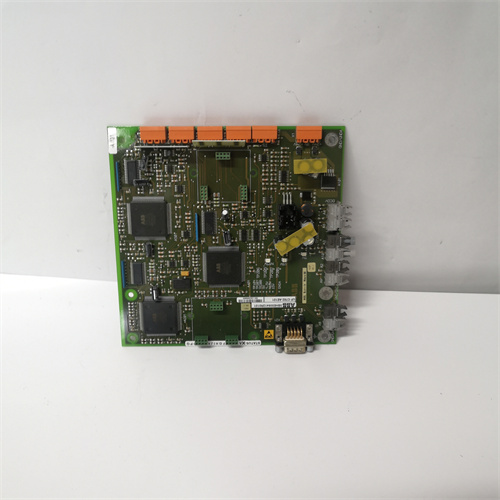

ABB XO16N1-B20和XO16N1-C3.0是两款功能互补的工业自动化控制模块,广泛应用于电气控制系统、过程控制及智能制造领域。以下是两款产品的核心功能与技术特点概述:

一、ABB XO16N1-B20

模块化控制核心

采用模块化设计,支持控制室安装,适用于构建分布式控制系统。内置TFT/LED触摸屏面板,支持多协议通信(如EtherCAT、Profinet),并兼容主流工业总线协议,便于与其他设备无缝集成。

技术参数

-工作电压:220VAC

-处理速度:15Hz

-程序容量:3MB

-数据容量:2MB

-防护等级:IP20(适用于洁净工业环境)

应用场景

用于机器人焊接工作站、自动化生产线监控、电力系统保护等场景,可实现参数管理、轨迹控制及数据通信功能。

二、ABB XO16N1-C3.0

过程控制与数据管理

集成数据采集、温度控制及独立计时功能,常用于精密涂胶、烘箱温度管理等工艺流程。例如,在电梯轿门涂胶生产线中,该模块可独立控制16个工位的温度与加热时间,确保胶水固化质量。

技术参数

-工作电压:24VDC

-接口类型:RS485、以太网

-环境适应性:-10℃~60℃,湿度85%

-认证标准:UL认证

应用场景

适用于化工、食品包装、汽车制造等领域的过程控制,可优化工艺参数并减少人为干预。

三、共同特点

高可靠性

两款模块均采用冗余设计,支持故障自诊断与热插拔维护,MTBF(平均无故障时间)超过50,000小时。

开放兼容性

支持多种编程语言(如LD、FBD),可与西门子、施耐德等品牌设备协同工作,降低系统集成成本。

智能化扩展

可通过添加触摸屏、传感器或变位机模块,实现复杂控制逻辑(如电弧跟踪、伺服压力控制)。

四、适用行业

工业自动化:机器人焊接、装配线控制

能源电力:变电站保护、配电系统监测

过程制造:化工反应釜温度控制、食品包装线管理

智能制造:数字孪生系统数据采集、预测性维护

ABB XO16N1-B20 and XO16N1-C3.0 are two complementary industrial automation control modules,widely used in electrical control systems,process control and intelligent manufacturing.The following is an overview of the core functions and technical features of the two products:

1.ABB XO16N1-B20

Modular control core

Adopts modular design,supports control room installation,and is suitable for building distributed control systems.Built-in TFT/LED touch screen panel,supports multi-protocol communication(such as EtherCAT,Profinet),and is compatible with mainstream industrial bus protocols,facilitating seamless integration with other devices.

Technical parameters

-Operating voltage:220VAC

-Processing speed:15Hz

-Program capacity:3MB

-Data capacity:2MB

-Protection level:IP20(suitable for clean industrial environments)

Application scenarios

Used in scenarios such as robot welding workstations,automated production line monitoring,power system protection,etc.,it can realize parameter management,trajectory control and data communication functions.

2.ABB XO16N1-C3.0

Process control and data management

Integrated data acquisition,temperature control and independent timing functions,commonly used in process flows such as precision gluing and oven temperature management.For example,in the elevator door gluing production line,the module can independently control the temperature and heating time of 16 stations to ensure the quality of glue curing.

Technical parameters

-Working voltage:24VDC

-Interface type:RS485,Ethernet

-Environmental adaptability:-10℃~60℃,humidity 85%

-Certification standard:UL certification

Application scenarios

Suitable for process control in the fields of chemical,food packaging,automobile manufacturing,etc.,which can optimize process parameters and reduce human intervention.

3.Common features

High reliability

Both modules adopt redundant design,support fault self-diagnosis and hot-swap maintenance,and MTBF(mean time between failures)exceeds 50,000 hours.

Open compatibility

Supports multiple programming languages(such as LD,FBD),can work with brand equipment such as Siemens and Schneider,and reduce system integration costs.

Intelligent expansion

Complex control logic(such as arc tracking,servo pressure control)can be realized by adding touch screens,sensors or positioner modules.

IV.Applicable industries

Industrial automation:robot welding,assembly line control

Energy and power:substation protection,distribution system monitoring

Process manufacturing:chemical reactor temperature control,food packaging line management

Intelligent manufacturing:digital twin system data acquisition,predictive maintenance