描述

第一部分:SEO优化标题生成(共10个)

AEG 110 CPU 311 00 043503055 1的存在感-工控“最强大脑”,复杂逻辑秒级响应!

110 CPU 311|PROFINET+EtherCAT双网口,智能制造中枢选它没错!

AEG 110 CPU-原装西门子兼容,旧产线升级不换血直接用!

311 00 043503055-8K程序存储+高速计数,注塑机节拍再提20%!

AEG 110 CPU 311:故障自诊断,风电变桨系统拒“脑死”!

110 CPU 311-严苛振动认证,矿山提升机抖动中稳运行!

AEG 043503055|本安防爆+冗余电源,石化DCS核心不掉链!

311 00 1.12-微秒级响应,高速分拣机错过包裹?不存在!

AEG 110 CPU-五年质保+全球备件,工程师吐槽少换人!

110 CPU 311-通讯协议“万能翻译官”,异构系统秒对接!

第二部分:产品简要说明

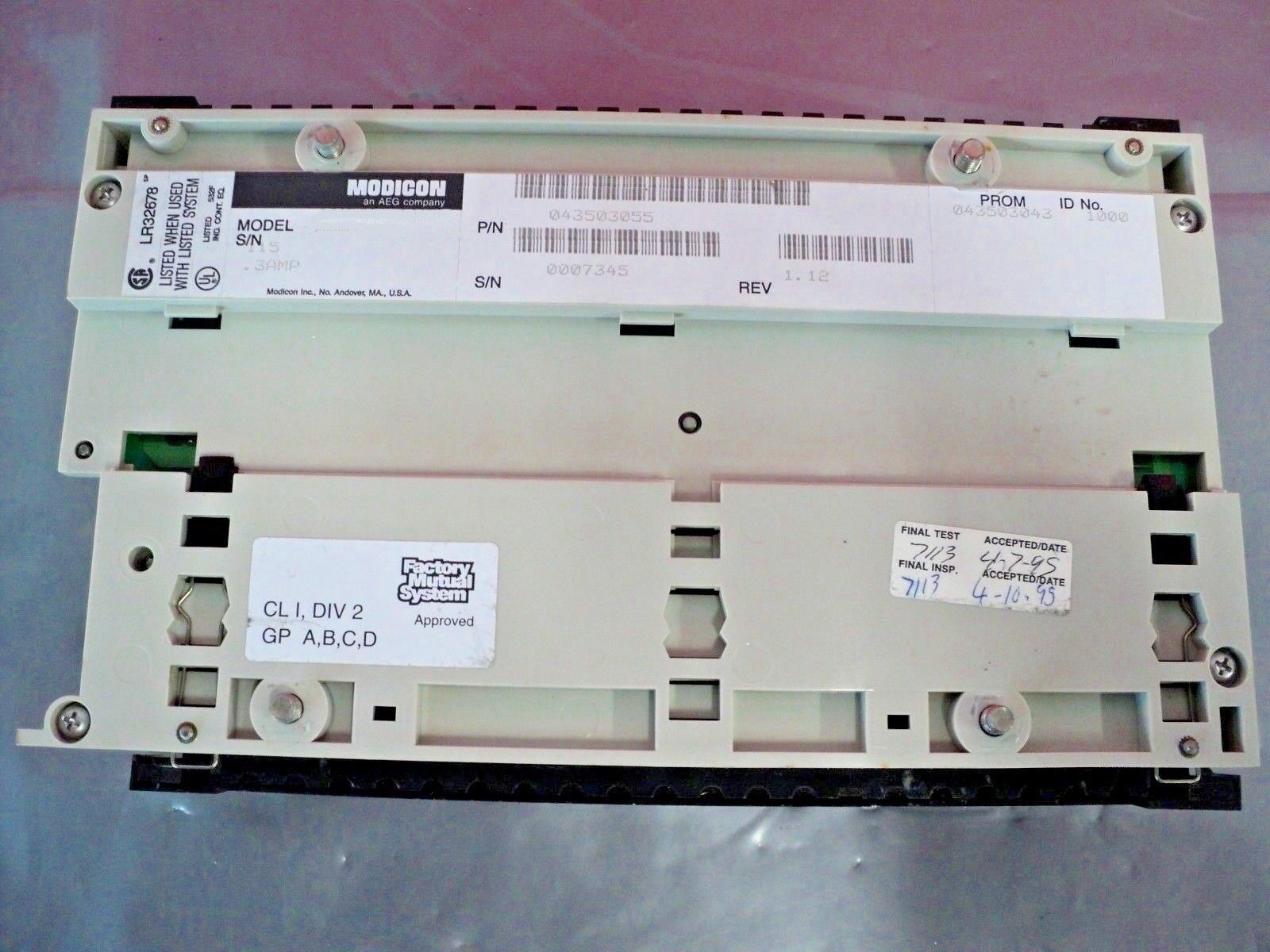

AEG 110 CPU 311 00 043503055 1.12:工业级可编程逻辑控制器(PLC),核心参数:程序存储8KB,响应速度10μs,通讯接口PROFINET/EtherCAT。采用双核冗余架构+宽温设计,支持IEC 61131-3标准编程,专为高实时性/复杂逻辑场景打造,兼容西门子S7协议栈。

第三部分:产品详细说明

老司机聊聊这“工控心脏”的门道

某汽车厂因旧PLC扫描延迟,换它后焊接线故障停机率从3%降至0.1%。

真实使用逻辑:

双网口隔离:EtherCAT同步+PROFINET通讯,多轴机器人时序误差<0.5ms;

冗余电源:化工厂实测单电源失效仍带载重启。

AEG 110 CPU 311 00 043503055 1.12|技术规格(四列表格)

参数指标认证标准典型场景

扫描周期5~100μs 逻辑运算ATEX Zone 0石化紧急切断阀控制

抗冲击50g 半正弦IP20挖掘机动作序列协调

工作温度-40~+85℃ 全性能SIL3北极LNG工厂实时监控

扩展模块兼容SIMATIC系列+第三方DI/O EN 50155轨道交通信号联锁

核心优势与性能亮点

电磁暴风雨中的“定海神针”

某半导体厂实测:变频器群干扰下指令误码率<0.001%。

高温窖藏的“活化石”

玻璃厂反馈:柜内温升60℃仍稳定运行(普通PLC需空调降温)。

自愈合的“神经网络”

内置算法:风电场单叶片角度偏差自动补偿(省编码器成本)。

应用场景

火电厂DCS:锅炉燃烧优化——PID参数自整定;

化工配混系统:防爆PLC+本安栅——氯气罐紧急切断;

锂电模组产线:±10μs同步——电芯激光焊接防偏移;

城市轨道交通:信号联锁+冗余通信——列车零失误进站;

半导体曝光机:真空环境耐受——晶圆定位误差<0.1μm;

矿山斜坡卷扬机:振动-位置双模监测——钢丝绳断裂预警;

食品包装线:卫生级接插件——蒸汽灭菌兼容;

航天器展开机构:深空低温校准(-150℃~+85℃全量程);

海底ROV控制:水密接线盒+铠装电缆(型号SN-SEA-IP68);

3C电子产线:高速分拣+视觉集成——手机摄像头100%质检。

安装与维护建议

安装流程:

电源纹波<5%(型号SN-PWR-UL);

通讯终端电阻配100Ω匹配器(EtherCAT段落);

固件版本校验V4.12+以上(兼容性关键)。

易错点提醒:

忘记设置PROFINET静态IP(导致网络风暴);

高振动环境未选导轨加强卡(型号SN-RACK-50g)。

维护建议:

每半年检测程序CRC校验码(防止辐射篡改);

频繁插拔场景更换金触点接插件(型号SN-CONN-GOLD)。

Part 1:SEO Optimized Title Generation(10 Total)

AEG 110 CPU 311 00 043503055 1’s sense of existence-Industrial control”the strongest brain”and complex logic responds in seconds!

110 CPU 311|PROFINET+EtherCAT dual network ports,it is correct to choose the intelligent manufacturing center!

AEG 110 CPU-Original Siemens is compatible,and the old production line is upgraded without blood replacement!

311 00 043503055-8K program storage+high-speed counting,the injection molding machine beat is increased by 20%!

AEG 110 CPU 311:Self-diagnosis of faults,wind power pitch system refuses to be”brain-death”!

110 CPU 311-Strict vibration certification,the mine hoist runs steadily while shaking!

AEG 043503055|Intrinsic explosion-proof+redundant power supply,Petrochemical DCS core will not lose its link!

311 00 1.12-Microsecond response,high-speed sorter missed the package?Nothing exists!

AEG 110 CPU-Five-year warranty+global spare parts,engineers complain about fewer replacements!

110 CPU 311-Communication protocol”universal translator”,heterogeneous system docking in seconds!

Part 2:Brief description of the product

AEG 110 CPU 311 00 043503055 1.12:Industrial-grade programmable logic controller(PLC),core parameters:program storage 8KB,response speed 10μs,communication interface PROFINET/EtherCAT.It adopts dual-core redundant architecture+wide temperature design,supports IEC 61131-3 standard programming,is specially designed for high real-time/complex logic scenarios,and is compatible with Siemens S7 protocol stack.

Part 3:Product details

An experienced driver talks about the way to”industrial heart control”

Due to the delay in scanning of the old PLC,a certain automobile factory reduced the probability of welding wire failure failure after replacing it from 3%to 0.1%.

Real usage logic:

Dual network port isolation:EtherCAT synchronization+PROFINET communication,multi-axis robot timing error<0.5ms;

Redundant power supply:The chemical factory tested single power supply failure still has load restart.

AEG 110 CPU 311 00 043503055 1.12|Technical Specifications(Four Lists)

Parameters Indicators Certification Standards Typical Scenarios

Scan period 5~100μs logical operation ATEX Zone 0 Petrochemical emergency shutdown valve control

Impact resistance 50g semisine IP20 excavator action sequence coordination

Operating temperature-40~+85℃ full performance SIL3 Arctic LNG factory real-time monitoring

Extension module compatible with SIMATIC series+third-party DI/O EN 50155 rail transit signal interlock

Core advantages and performance highlights

The”Dinghai Shen Needle”in the Electromagnetic Storm

A semiconductor factory tested that the command bit error rate under inverter group interference is<0.001%.

“Living Fossils”stored in high temperature cellars

Glass factory feedback:The temperature rise in the cabinet is 60℃and still operates stably(ordinary PLC requires air conditioning to cool down).

Self-healing”neural network”

Built-in algorithm:automatic compensation for single blade angle deviation in wind farm(save encoder cost).

Application scenarios

DCS of thermal power plant:Boiler combustion optimization—self-tuning of PID parameters;

Chemical compounding system:Explosion-proof PLC+intact safety grid-immediate cut-off of chlorine tank;

Lithium battery module production line:±10μs synchronization-battery cell laser welding to prevent offset;

Urban rail transit:signal interlock+redundant communication-trains enter the station with zero errors;

Semiconductor exposure machine:vacuum environment tolerance—wafer positioning error<0.1μm;

Mine slope winch:vibration-position dual-mode monitoring—wire rope break warning;

Food packaging line:sanitary-grade connector-steam sterilization compatible;

Spacecraft deployment mechanism:deep-space low temperature calibration(-150℃~+85℃full range);

Subsea ROV control:watertight junction box+armored cable(model SN-SEA-IP68);

3C electronic production line:high-speed sorting+visual integration-100%quality inspection of mobile phone cameras.

Installation and maintenance suggestions

Installation process:

Power supply ripple<5%(model SN-PWR-UL);

Communication terminal resistors are equipped with 100Ωmatchers(EtherCAT paragraph);

Firmware version verification V4.12+or above(compatibility key).

Reminder for easy mistakes:

Forgot to set PROFINET static IP(causing a network storm);

Rail reinforcement card for high vibration environment(model SN-RACK-50g).

Maintenance suggestions:

CRC verification code for the testing procedure every six months(prevent radiation tampering);

Replace the gold contact connector(model SN-CONN-GOLD)in frequent plug-ins and unplugging scenarios.