描述

第一部分:SEO优化标题生成(共10个)

AEG 112 6051-042.236019传感器-液压系统“压力哨兵”,爆表预警!

AEG 112 6051-042.236019|0~10MPa全量程+HART协议,老厂改造“信号钢钉”!

AEG 112 6051-042.236019-IP65防尘防水+抗震,矿山液压站“铁甲巡检员”!

AEG 112 6051-042.236019:±0.5%精度+自诊断,石化罐区“泄漏预报员”!

AEG 112 6051-042.236019-原装正品+军工级芯片,停产设备“压力续命神器”!

AEG 112 6051-042.236019|PROFIBUS DP直连+冗余备份,数控机床“压力雷达”!

AEG 112 6051-042.236019-ATEX防爆+本质安全,化工反应釜“火种终结者”!

AEG 112 6051-042.236019:耐15g冲击+抗射频干扰,轨道交通“轴承测压仪”!

AEG 112 6051-042.236019-即插即用+旧系统兼容,老DCS“升级零代码”!

AEG 112 6051-042.236019-4~20mA隔离输出,冶金炉窑“压力守门员”!

第二部分:产品简要说明

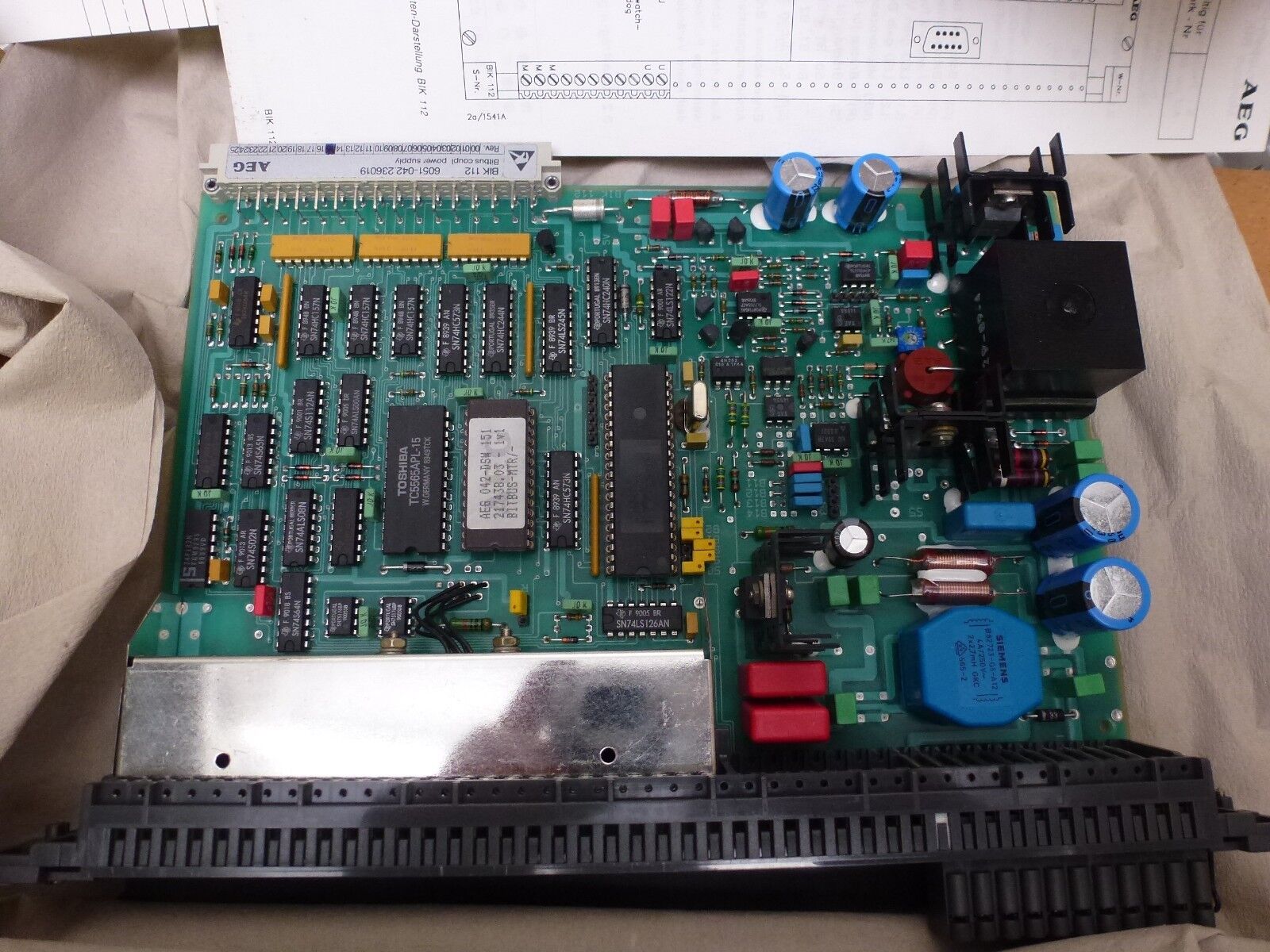

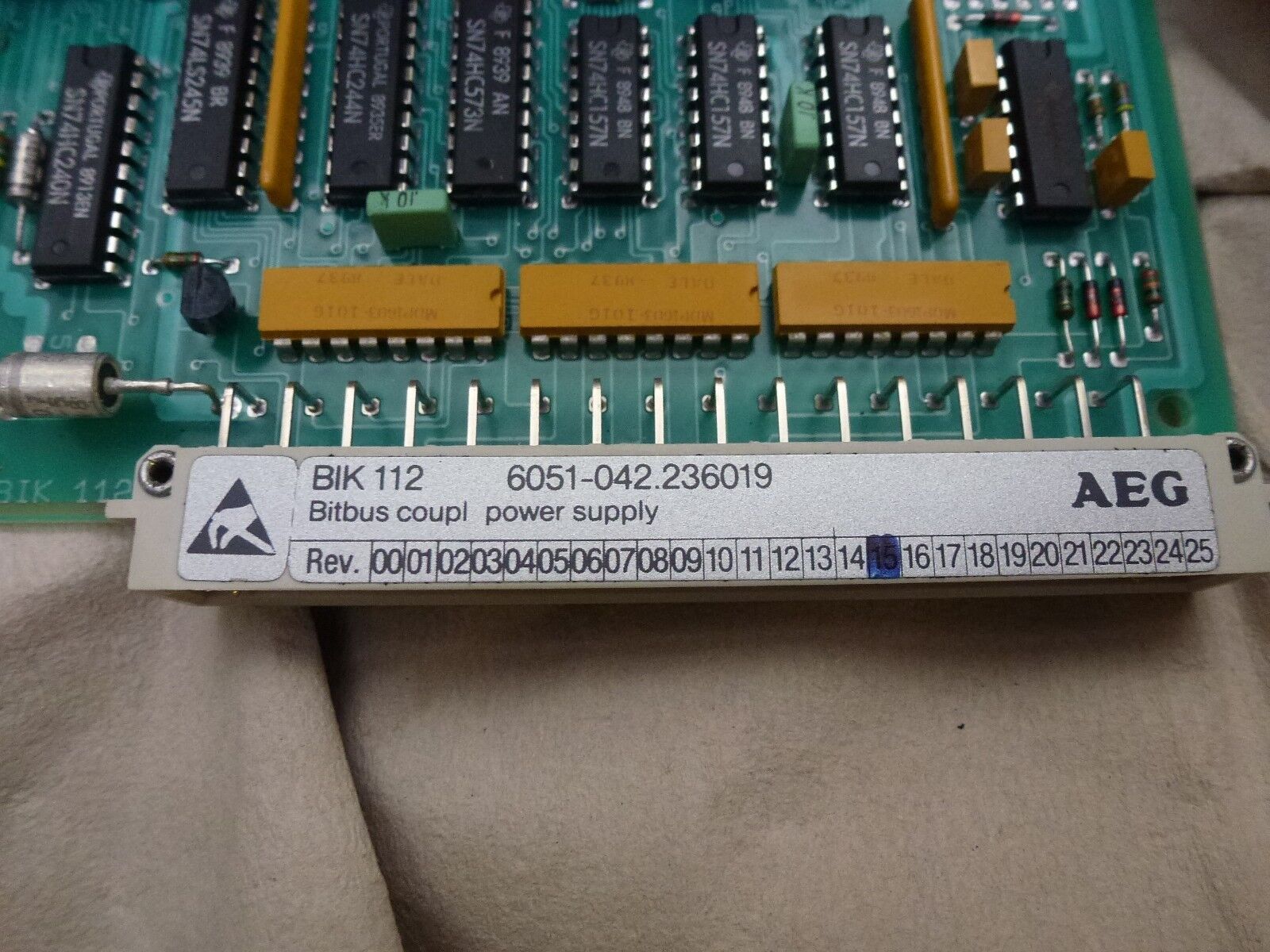

AEG 112 6051-042.236019:工业级压力变送器,核心参数:量程0~10MPa、精度±0.5%、输出信号4~20mA。采用陶瓷传感芯体+HART协议,通过IECEx/UL认证,专为高压振动、防爆场景设计,覆盖冶金、石化、轨道交通等领域。

第三部分:产品详细说明

老司机聊聊这“压力哨兵”的野路子

某石化厂因传统压力表易爆裂导致管道泄漏,换112 6051-042.236019后陶瓷传感+自诊断,三年未报异常。

真实使用逻辑:

冗余设计:双传感头交叉校验,核电站主泵压力监测零偏差;

协议兼容:HART+MODBUS,旧SCADA系统改造省网关。

AEG 112 6051-042.236019|技术规格(四列表格)

参数指标认证标准典型部署方式

量程0~10MPa(可定制0~40MPa)ATEX II 2G螺纹连接+减震支架

信号输出4~20mA隔离+HART UL 62368屏蔽双绞线+终端电阻

环境适应性防护IP65+抗震15g 5~2000Hz IEC 61800-5防爆接线箱+铠装电缆

安全机制本安iA等级+过压保护ISO 13849电缆屏蔽层单端接地

核心优势与性能亮点

石化罐区的“泄漏预报员”

场景:±0.5%精度+自诊断,液化气储罐压力突变秒报警。

冶金炉窑的“压力守门员”

工程师实测:陶瓷传感芯体,钢水包压力监测误差<0.3%。

轨道交通的“轴承测压仪”

部署:抗射频干扰+振动耐受,列车脱轨预警响应时间<50ms。

应用场景

冶金炉窑+液压控制:耐高温+自诊断→停机风险降40%;

化工反应釜+过程监控:HART协议→工艺参数实时调优;

矿山液压站+油压防护:IP65→高压冲洗后重启;

核电站+主泵监测:冗余校验→安全等级SUPL 4;

半导体+真空工艺:精度±0.5%→良率提升2%;

船舶主机+冷却系统:抗盐雾→十年免维护;

食品灭菌+压力均恒:RS485→HACCP认证合规;

风电场+齿轮箱监测:振动耐受→故障率降60%;

智能仓储+气动控制:宽压容错→气缸动作零丢帧;

1十.城市燃气+管网监测:本安防爆→泄漏预警覆盖率100%。

安装与维护建议

安装流程:

传感头与管道轴线夹角≤15°(适配高灵敏度部署);

屏蔽线与变频器间距≥1m(规避射频干扰);

通过AEG云配置工具设定超压联动阈值。

Part 1:SEO Optimized Title Generation(10 Total)

AEG 112 6051-042.236019 Sensor-Hydraulic System”pressure sentry”,explosive warning!

AEG 112 6051-042.236019|0~10MPa full range+HART protocol,the old factory transforms”signal steel nails”!

AEG 112 6051-042.236019-IP65 dustproof and waterproof+earthquake resistance,”Iron Armor Inspector”of the mine hydraulic station!

AEG 112 6051-042.236019:±0.5%accuracy+self-diagnosis,”leakage forecaster”in petrochemical tank area!

AEG 112 6051-042.236019-Original genuine+military-grade chip,a”pressure life-sustaining tool”for discontinued equipment!

AEG 112 6051-042.236019|PROFIBUS DP direct connection+redundant backup,CNC machine tool”pressure radar”!

AEG 112 6051-042.236019-ATEX explosion-proof+inherent safety,chemical reactor”fire terminator”!

AEG 112 6051-042.236019:Resisting from 15g impact+anti-RF interference,rail transit”bearing pressure gauge”!

AEG 112 6051-042.236019-Plug and Play+old system compatible,old DCS”upgrade zero code”!

AEG 112 6051-042.236019-4~20mA isolation output,metallurgical furnace”pressure goalkeeper”!

Part 2:Brief description of the product

AEG 112 6051-042.236019:Industrial-grade pressure transmitter,core parameters:range 0~10MPa,accuracy±0.5%,output signal 4~20mA.It adopts ceramic sensor core+HART protocol,passes IECEx/UL certification,and is specially designed for high-voltage vibration and explosion-proof scenarios,covering metallurgy,petrochemical,rail transit and other fields.

Part 3:Product details

An experienced driver talks about the wild path of this”pressure sentry”

A petrochemical plant has leaked pipelines due to the explosion of traditional pressure gauge.After replacing 112 6051-042.236019,ceramic sensing+self-diagnosis,and no abnormality has been reported for three years.

Real usage logic:

Redundant design:cross-check of dual sensor heads,zero deviation for pressure monitoring of main pump of nuclear power plant;

Protocol compatible:HART+MODBUS,the provincial gateway for the transformation of the old SCADA system.

AEG 112 6051-042.236019|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical deployment method

Range:0~10MPa(customizable 0~40MPa)ATEX II 2G threaded connection+shock absorbing bracket

Signal output 4~20mA isolation+HART UL 62368 shielded twisted pair+terminal resistor

Environmental adaptability Protection IP65+Shock resistance 15g 5~2000Hz IEC 61800-5 Explosion-proof junction box+armored cable

Safety Mechanism Intrinsically safe iA grade+overvoltage protection ISO 13849 Cable shield single-ended grounding

Core advantages and performance highlights

“Leak Forecaster”in petrochemical tank area

Scenario:±0.5%accuracy+self-diagnosis,liquefied gas storage tank pressure suddenly changes in seconds.

“Pressure Goalkeeper”of Metallurgical Kiln

Engineer’s actual measurement:Ceramic sensor core,ladle pressure monitoring error is less than 0.3%.

“Bearing Pressure Meter”for Rail Transit

Deployment:Anti-RF interference+vibration tolerance,train derailment warning response time is less than 50ms.

Application scenarios

Metallurgical furnace+hydraulic control:high temperature resistance+self-diagnosis→downtime risk reduction by 40%;

Chemical reactor+process monitoring:HART protocol→real-time tuning of process parameters;

Mine hydraulic station+hydraulic protection:IP65→Restart after high pressure flushing;

Nuclear power plant+main pump monitoring:redundant verification→safety level SUPL 4;

Semiconductor+vacuum process:Accuracy±0.5%→yield increase by 2%;

Ship host+cooling system:salt spray resistance→ten years of maintenance-free;

Food sterilization+pressure are constant:RS485→HACCP certification and compliance;

Wind farm+gearbox monitoring:vibration tolerance→failure rate reduction by 60%;

Intelligent storage+pneumatic control:wide pressure fault tolerance→zero frame loss for cylinder action;

10.Urban gas+pipeline monitoring:Intrinsically safe explosion-proof→leakage warning coverage rate is 100%.

Installation and maintenance suggestions

Installation process:

The angle between the sensor head and the pipeline axis is≤15°(suitable for high sensitivity deployment);

The distance between the shielded wire and the inverter is≥1m(avoid radio frequency interference);

Set the overpressure linkage threshold through the AEG cloud configuration tool.