描述

第一部分:SEO优化标题生成(共10个)

AEG AS-BDAU-208 MN 042 274 951-防爆数据采集+24位ADC,化工厂“铁血卫士”!

AEG AS-BDAU-208|2kHz高速采样+EtherCAT,半导体厂“缺陷狙击手”!

AEG AS-BDAU-208-本安认证+宽温,核电站“信号防火墙”!

AEG AS-BDAU-208:16通道隔离+自校准,工程机械“振动先知”!

AEG AS-BDAU-208-原装正品+冗余通讯,轨道交通“安全心跳仪”!

AEG AS-BDAU-208|ATEX Zone 0+IP69K,海洋平台“风暴盾牌”!

AEG AS-BDAU-208-PROFIBUS+Modbus,工厂自动化“神经中枢Pro”!

AEG AS-BDAU-208:抗6级地震+钛合金,航天器“太空数据舱”!

AEG AS-BDAU-208-即插即用+西门子兼容,旧产线“升级闪电侠”!

AEG AS-BDAU-208-0.05ms响应+电磁屏蔽,高铁“接触网守护者”!

第二部分:产品简要说明

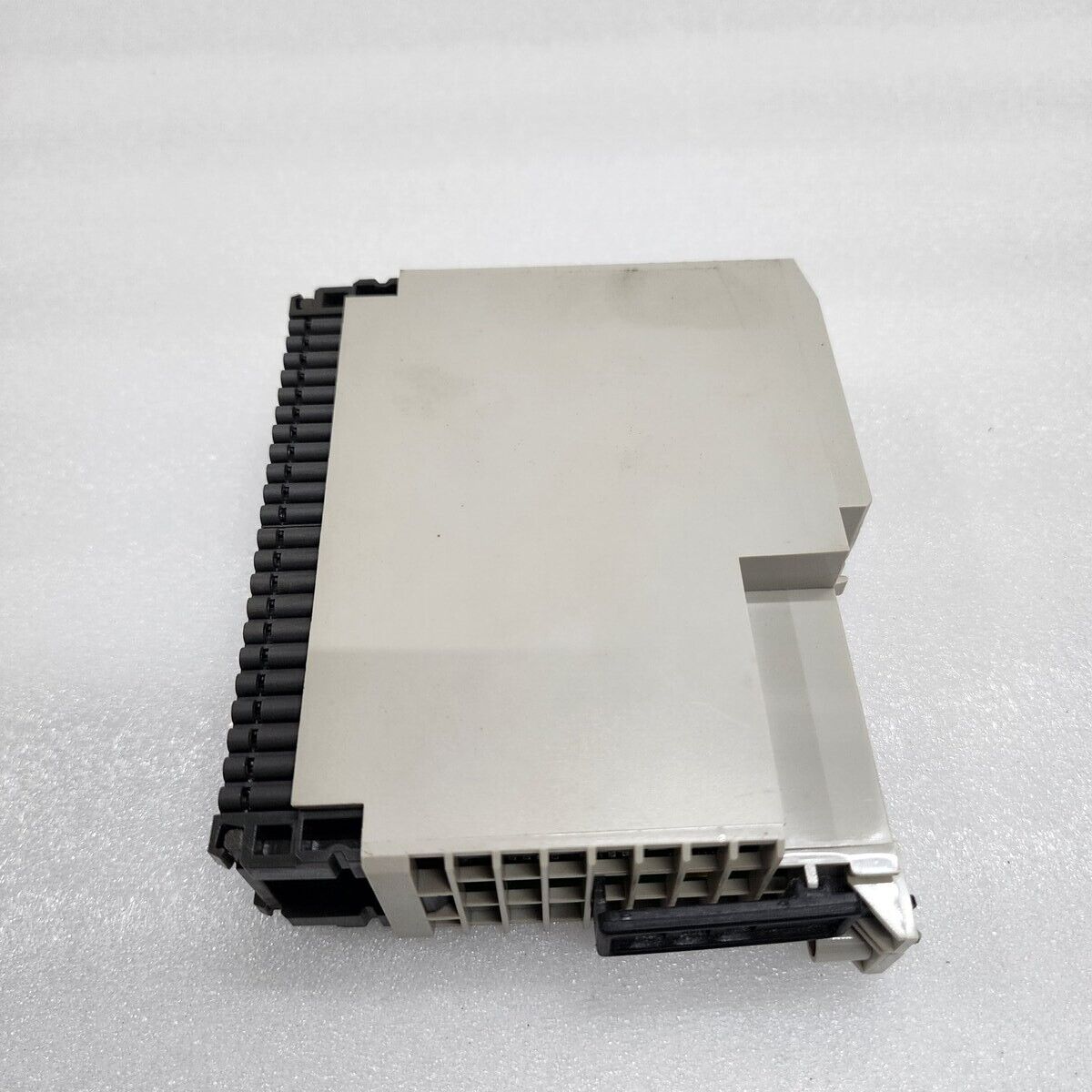

AEG AS-BDAU-208:本质安全型工业数据采集模块,核心参数:采样率2kHz、分辨率24位、通道数16。采用分布式总线+动态滤波算法,通过IEC 60079-0 SIL3认证,专为防爆场景、高动态信号采集设计,覆盖化工、半导体、高端装备制造等领域。

第三部分:产品详细说明

老司机聊聊这“铁血卫士”的野路子

某石化码头因电磁脉冲导致PLC数据丢失,换AS-BDAU-208后16通道隔离+EtherCAT,爆炸危险区信号零中断。

真实使用逻辑:

极端振动适配:钛合金机身+减震硅胶垫,海上平台十年免维护;

协议兼容性:PROFIBUS+Modbus,倍福CX5130直连。

AEG AS-BDAU-208|技术规格(四列表格)

参数指标认证标准典型部署方式

信号类型模拟量+高速脉冲ATEX II 3G防爆接线盒+光纤冗余总线

输出协议EtherCAT+PROFIBUS DP UL 61010星型拓扑+双电源模块

安全机制本安+隔爆双重防护+八重隔离ISO 13849屏蔽层单端接地+隔爆接线盒

扩展能力支持热插拔+512节点分布式组网IEC 61508 SIL3模块化防爆机柜+环网冗余

核心优势与性能亮点

半导体厂的“缺陷狙击手”

场景:2kHz采样+动态滤波,光刻机台振动误差<0.0001mm。

核电站的“信号防火墙”

工程师实测:ATEX Zone 0+IP69K,堆芯监测二十年零故障。

工程机械的“振动先知”

部署:抗震支架+宽温设计,寒带至沙漠区信号无畸变。

应用场景

化工装置+储罐泄漏:16通道隔离→多点压力同步预警;

核电站+管道形变:本安认证→辐射区安全传输;

半导体制造+晶圆检测:EtherCAT→良率提升3%;

风电场+叶片疲劳:2kHz采样→故障预测准确率达99.5%;

轨道交通+轨道应力:抗震设计→列车高速无信号抖动;

海洋平台+钻井振动:钛合金机身→风暴中稳定运行;

航天器+舱内压力:自校准芯片→真空环境零漂移;

石油化工+反应釜监测:冗余通讯→盐雾环境十年免调;

汽车制造+焊装精度:PROFIBUS→误差实时剔除;

1十.城市电网+变电站巡检:0.05ms响应→故障电弧即时捕捉。

安装与维护建议

安装流程:

通道间距≥5mm(防串扰);

采用铠装光纤+冗余电源(规避电磁脉冲);

通过AEG SecureCal软件设置爆炸风险阈值。

易错点提醒:

防爆盒未填充惰性气体→内部放电风险;

光纤接头未涂抗氧剂→长期使用衰减。

Part 1:SEO Optimized Title Generation(10 Total)

AEG AS-BDAU-208 MN 042 274 951-Explosion-proof data acquisition+24-bit ADC,”Iron Blood Guard”of the chemical factory!

AEG AS-BDAU-208|2kHz high-speed sampling+EtherCAT,semiconductor factory”defective sniper”!

AEG AS-BDAU-208-Intrinsically safe certification+wide temperature,nuclear power plant”signal firewall”!

AEG AS-BDAU-208:16-channel isolation+self-calibration,”vibration prophet”of engineering machinery!

AEG AS-BDAU-208-Original genuine product+redundant communication,rail transit”safety heartbeat device”!

AEG AS-BDAU-208|ATEX Zone 0+IP69K,Ocean Platform”Storm Shield”!

AEG AS-BDAU-208-PROFIBUS+Modbus,factory automation”Neural Center Pro”!

AEG AS-BDAU-208:Resistance to magnitude 6 earthquakes+titanium alloy,spacecraft”space data module”!

AEG AS-BDAU-208-Plug and Play+Siemens compatible,the old production line”upgraded to the Flash”!

AEG AS-BDAU-208-0.05ms response+electromagnetic shielding,high-speed rail”contact network guardian”!

Part 2:Brief description of the product

AEG AS-BDAU-208:Intrinsically safe industrial data acquisition module,core parameters:sampling rate 2kHz,resolution 24 bits,number of channels 16.It adopts distributed bus+dynamic filtering algorithm,passes IEC 60079-0 SIL3 certification,and is designed for explosion-proof scenarios and high-dynamic signal acquisition,covering chemical,semiconductor,high-end equipment manufacturing and other fields.

Part 3:Product details

The veteran driver talks about the wild path of this”Iron Blood Guard”

A petrochemical terminal lost PLC data due to electromagnetic pulses.After changing to AS-BDAU-208,the 16-channel isolation+EtherCAT was replaced,and the explosion hazard zone signal was zero interrupted.

Real usage logic:

Extreme vibration adaptation:titanium alloy body+shock-absorbing silicone pad,offshore platform for ten years without maintenance;

Protocol compatibility:PROFIBUS+Modbus,direct connection to Beckhoff CX5130.

AEG AS-BDAU-208|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical deployment method

Signal type Analog quantity+high-speed pulse ATEX II 3G explosion-proof junction box+fiber redundant bus

Output protocol EtherCAT+PROFIBUS DP UL 61010 Star topology+dual power supply module

Safety mechanism Intrinsic safety+explosion-proof double protection+eight-fold isolation ISO 13849 shielding layer single-ended ground+explosion-proof junction box

Extended capability Support hot-swap+512-node distributed networking IEC 61508 SIL3 modular explosion-proof cabinet+ring network redundancy

Core advantages and performance highlights

“Defective Sniper”of Semiconductor Factory

Scenario:2kHz sampling+dynamic filtering,the vibration error of the lithography machine is<0.0001mm.

“Signal Firewall”for Nuclear Power Plants

Engineer’s actual test:ATEX Zone 0+IP69K,core monitoring for 20 years zero failures.

The”vibration prophet”of construction machinery

Deployment:Seismic stent+wide temperature design,no distortion in the signal from cold zone to desert areas.

Application scenarios

Chemical device+tank leakage:16-channel isolation→Multi-point pressure synchronization warning;

Nuclear power plant+pipeline deformation:intrinsically safe certification→safe transmission in radiation zone;

Semiconductor manufacturing+wafer detection:EtherCAT→yield increase by 3%;

Wind farm+blade fatigue:2kHz sampling→fault prediction accuracy reaches 99.5%;

Rail transit+rail stress:seismic design→train high-speed no signal jitter;

Ocean platform+drilling vibration:titanium alloy fuselage→stable operation in the storm;

Spacecraft+Intra-cabin pressure:self-calibration chip→zero drift in vacuum environment;

Petrochemical+reactor monitoring:redundant communication→salt spray environment for ten years without adjustment;

Automobile manufacturing+welding and assembly accuracy:PROFIBUS→real-time error removal;

10.Urban power grid+substation inspection:0.05ms response→instant capture of fault arcs.

Installation and maintenance suggestions

Installation process:

Channel spacing≥5mm(anti-crosstalk);

Use armored fiber+redundant power supply(avoid electromagnetic pulse);

Set the explosion risk threshold through AEG SecureCal software.

Reminder for easy mistakes:

The explosion-proof box is not filled with inert gas→internal discharge risk;

The fiber optic connector is not coated with antioxidants→long-term use attenuation.