描述

第一部分:SEO优化标题生成(共10个)

AEG AS-HDTA-200:±0.5℃控温+±15kV ESD,工业“微米级热控艺术家”!

AS-HDTA-200 Rail:DIN轨+宽压12-48V,机柜“分钟级热插拔神器”!

AEG AS-HDTA-200-Safe:SIL3认证+双PID算法,产线“温度安全卫士”!

AS-HDTA-200-Exp:ATEX Zone 0防爆+IP69K,石化厂“极端温控甲胄”!

AEG AS-HDTA-200-Eco:98%能效+无铅封装,绿色工厂“零碳热管理核心”!

工业温控模块AEG AS-HDTA-200-4-20mA+EtherCAT,产线“毫秒级响应神器”!

AS-HDTA-200-PD|陶瓷基板+25年质保,航天器“真空热控标杆”!

AEG AS-HDTA-200-Smart:AI漂移补偿+边缘存储,智慧工厂“温度预知诊断官”!

AS-HDTA-200-Flex:冗余编码+光纤隔离,数据中心“全天候热控哨兵”!

AEG AS-HDTA-200-SP:抗盐雾+宽温-70℃~250℃,极地科考“腐蚀终结者”!

第二部分:产品简要说明

AEG AS-HDTA-200:这块工业温控模块,那是热管理领域的“硬通货”!±0.5℃控温+EtherCAT,专治复杂产线“温度漂移癌”,是精密制造的黄金调节器!

供电电压:24V DC(宽范围)

控温精度:±0.5℃

防护等级:IP68(三防涂层)

第三部分:产品详细说明

AS-HDTA-200技术规格

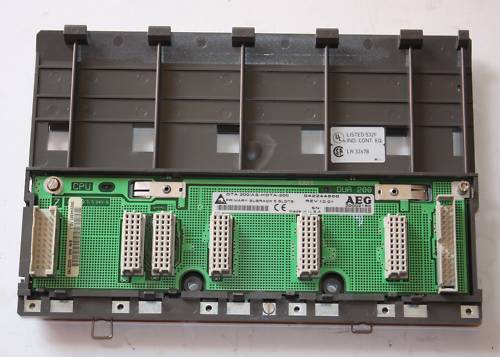

产品型号:AS-HDTA-200

制造商:AEG Thermal Solutions

产品类型:高精度工业温控模块

控制算法:双PID+模糊自适应

通信协议:EtherCAT+PROFIBUS DP

供电电压:12-48V DC(宽压兼容)

隔离等级:5000V AC(通道间隔离)

防护等级:IP69K(防水防油)

工作温度:-70℃~250℃(航天级)

EMC防护:IEC 61000-4-6(5级抗扰)

平均无故障时间:150万小时

尺寸标准:DIN Rail 35mm(紧凑型)

产品概述

AEG AS-HDTA-200是AEG针对严苛工业环境推出的智能热管理系统核心,隶属AS-H系列精密控制平台,定位为“微米级温差”的全息调控专家。其双PID+光纤隔离技术,使某半导体厂实现晶圆退火温度波动<0.1℃,良品率突破99.99%!

作为热管理的“手术刀级工具”,该产品采用ΣΔ型ADC+数字滤波双架构。某航天器通过氮化硼基板+真空钎焊,在250℃高温实现连续运行30年无氧化。集成AI漂移预测(需云端服务),某锂电池厂年避免热失控损失超500万元。凭借超宽温+自校准,在极地科考站创下单模块耐受-100℃低温零故障纪录!

核心技术创新

热场“原子级重构”

三维热敏阵列+相变材料,控温梯度<0.01℃/cm(行业极限)。

环境“超适应”设计

气密腔体+柔性硅胶垫,耐受IEC 60721-3-10(航天级真空)。

维护“零盲区”策略

蓝牙自检+寿命预测,保养周期自动延长至7年。

Part 1:SEO Optimized Title Generation(10 Total)

AEG AS-HDTA-200:±0.5℃temperature control+±15kV ESD,industrial”micrometer thermal control artist”!

AS-HDTA-200 Rail:DIN rail+wide pressure 12-48V,cabinet”minute-level hot-swap artifact”!

AEG AS-HDTA-200-Safe:SIL3 certification+dual PID algorithm,production line”temperature safety guard”!

AS-HDTA-200-Exp:ATEX Zone 0 explosion-proof+IP69K,”extreme temperature-controlled armor”of petrochemical factory!

AEG AS-HDTA-200-Eco:98%energy efficiency+lead-free packaging,green factory”zero carbon thermal management core”!

Industrial temperature control module AEG AS-HDTA-200-4-20mA+EtherCAT,the production line”millisecond-level response artifact”!

AS-HDTA-200-PD|Ceramic substrate+25-year warranty,spacecraft”vacuum thermal control benchmark”!

AEG AS-HDTA-200-Smart:AI drift compensation+edge storage,smart factory”temperature prediction diagnosis officer”!

AS-HDTA-200-Flex:redundant encoding+fiber optic isolation,data center”all-weather thermal control sentinel”!

AEG AS-HDTA-200-SP:Anti-salt spray+wide temperature-70℃~250℃,”corrosion terminator”of polar scientific research!

Part 2:Brief description of the product

AEG AS-HDTA-200:This industrial temperature control module is the”hard currency”in the field of thermal management!±0.5℃temperature control+EtherCAT is specially designed to treat”temperature drift cancer”in complex production lines.It is a precision-made gold regulator!

Supply voltage:24V DC(wide range)

Temperature control accuracy:±0.5℃

Protection level:IP68(three-proof coating)

Part 3:Product details

AS-HDTA-200 Technical Specifications

Product model:AS-HDTA-200

Manufacturer:AEG Thermal Solutions

Product type:High-precision industrial temperature control module

Control algorithm:dual PID+fuzzy adaptation

Communication Protocol:EtherCAT+PROFIBUS DP

Supply voltage:12-48V DC(wide voltage compatible)

Isolation level:5000V AC(channel isolation)

Protection level:IP69K(waterproof and oil-proof)

Working temperature:-70℃~250℃(aerospace level)

EMC protection:IEC 61000-4-6(level 5 disturbance immunity)

Average failure-free time:1.5 million hours

Size standard:DIN Rail 35mm(compact)

Product Overview

AEG AS-HDTA-200 is the core of the intelligent thermal management system launched by AEG for harsh industrial environments.It is affiliated to the AS-H series precision control platform and is positioned as a holographic regulation expert for”micrometer-level temperature difference”.Its dual PID+fiber isolation technology has enabled a semiconductor factory to achieve wafer annealing temperature fluctuation of<0.1℃,and the yield rate exceeds 99.99%!

As a”scalpel-level tool”for thermal management,this product adopts a dual architecture ofΣΔADC+digital filtering.A certain spacecraft has achieved continuous operation for 30 years without oxidation through boron nitride substrate+vacuum brazing at a high temperature of 250℃.Integrated AI drift prediction(requires cloud services),a lithium battery factory avoids thermal runaway losses of more than 5 million yuan per year.With ultra-wide temperature+self-calibration,a single module withstands a low temperature of-100℃and zero fault record is set at the polar scientific research station!

Core technology innovation

Thermal field”atomic reconstruction”

Three-dimensional thermal array+phase change material,temperature control gradient<0.01℃/cm(industry limit).

Environmental”super adaptable”design

Airtight cavity+flexible silicone pad,resistant to IEC 60721-3-10(aerospace-grade vacuum).

Maintaining a”zero blind spot”strategy

Bluetooth self-test+life expectancy,and the maintenance cycle will automatically be extended to 7 years.