描述

第一部分:SEO优化标题生成(共10个)

AEG C921 AS-C921-101高密度I/O模块-32通道+EtherNet/IP,产线升级“血管扩张剂”!

AEG C921 AS-C921-101|16AI+16AO+隔离保护,化工DCS“信号绝缘盾”!

AEG C921 AS-C921-101-IP65防护+宽压输入,户外光伏“数据避雷针”!

AEG C921 AS-C921-101:热插拔+自适应采样,数控机床“零停机魔术师”!

AEG C921 AS-C921-100-原装兼容+军工级芯片,进口PLC“停产续命卡”!

AEG C921 AS-C921-101|PROFIBUS DP+RS485,老厂改造“通信万能钥匙”!

AEG C921 AS-C921-101-ATEX Zone 2+本质安全,油气平台“火花灭火器”!

AEG C921 AS-C921-101:耐10g振动+抗射频干扰,轨道交通“信号定海神针”!

AEG C921 AS-C921-101-即插即用+西门子兼容,旧系统“缝合手术刀”!

AEG C921 AS-C921-101-4~20mA回路供电,冶金仪表“省线缆专家”!

第二部分:产品简要说明

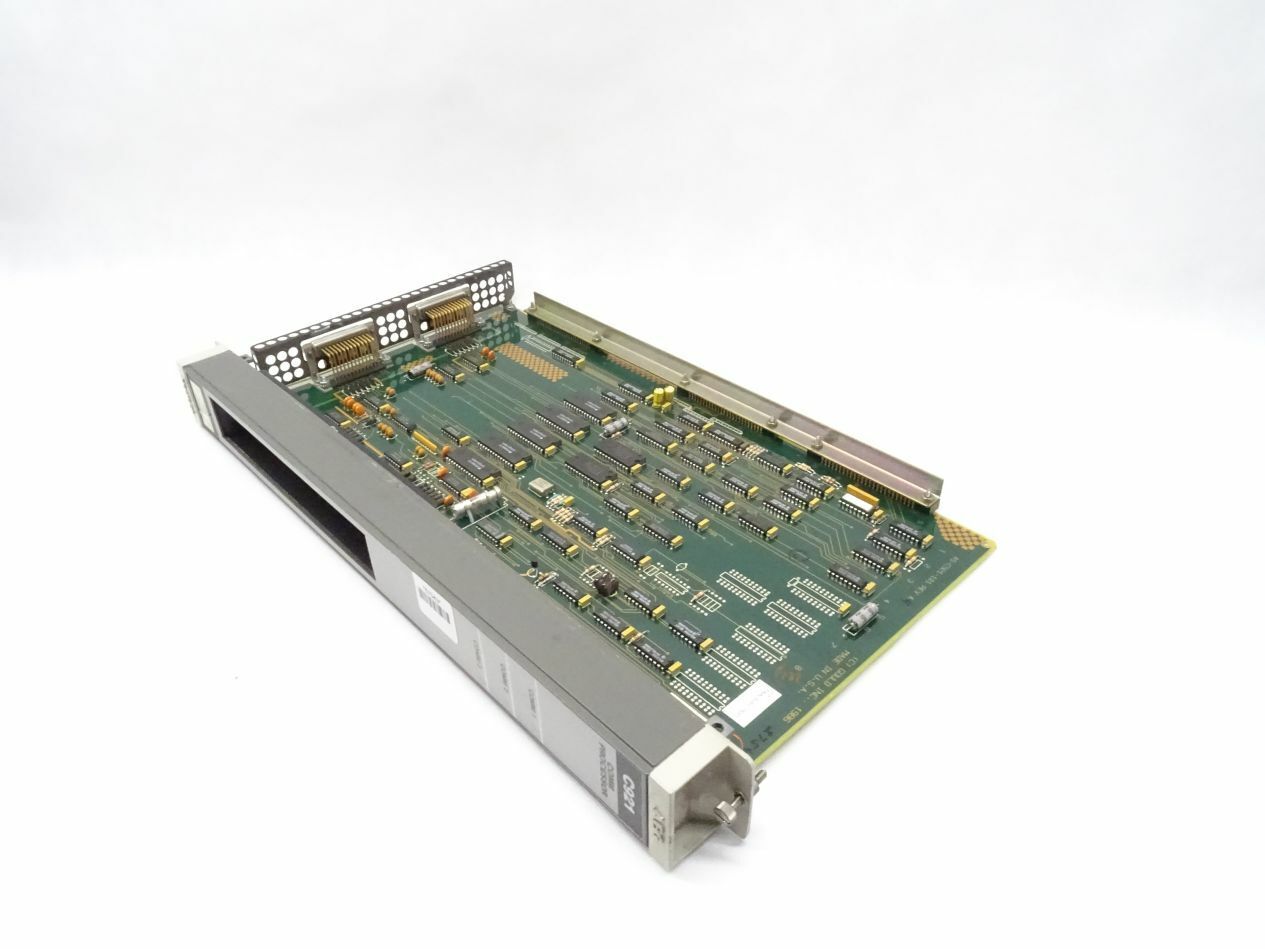

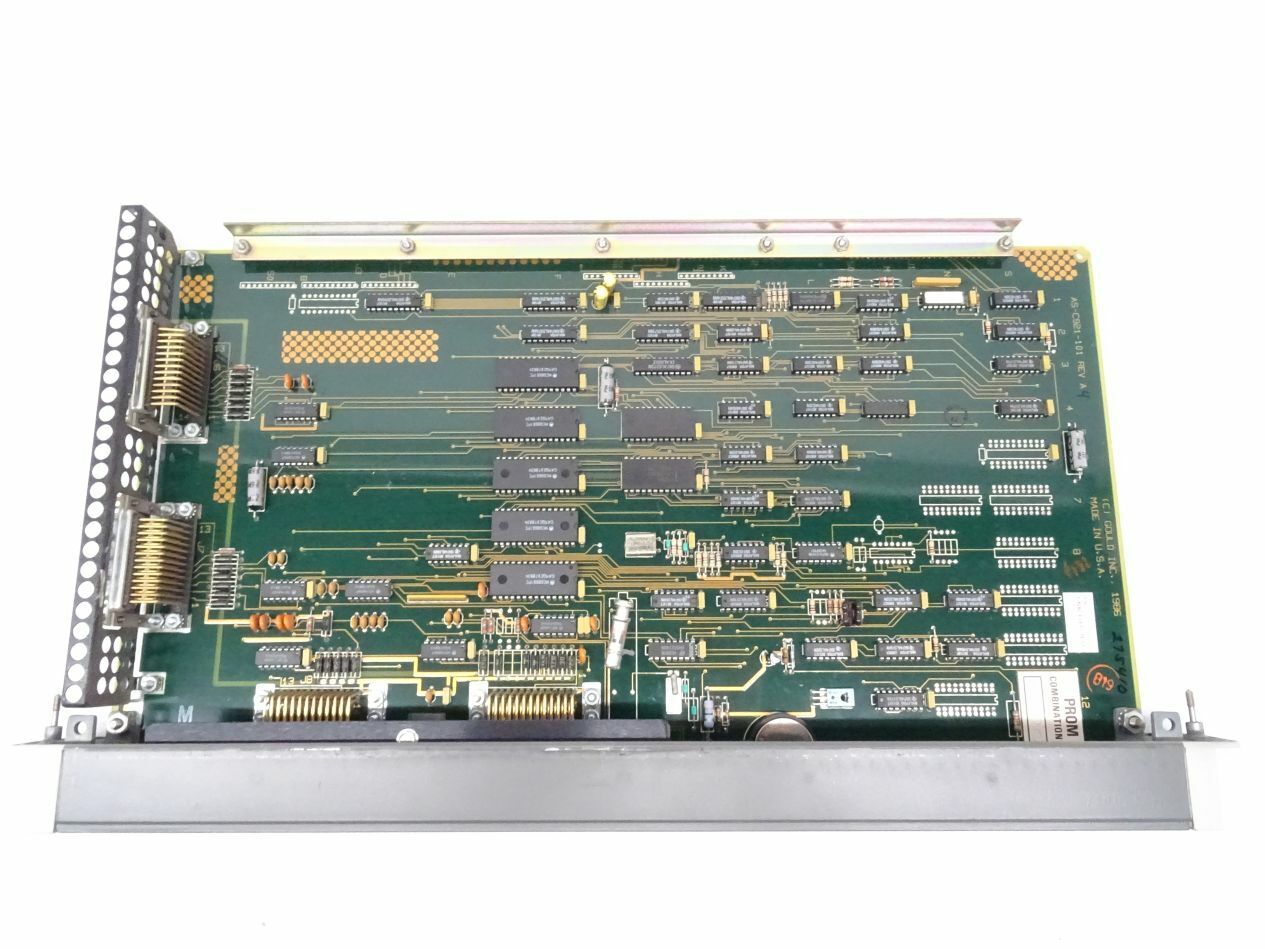

AEG C921 AS-C921-101:工业级高密度I/O模块,核心参数:32通道混合I/O、通信协议EtherNet/IP、隔离电压1500Vrms。采用FPGA动态采样+磁隔离技术,通过CE/ATEX认证,专为高密度信号采集、恶劣环境设计,覆盖智能制造、能源、轨道交通等领域。

第三部分:产品详细说明

老司机聊聊这“信号绝缘盾”的野路子

某化工厂因原装AO模块绝缘失效导致联锁误动,换C921 AS-C921-101后1500Vrms隔离+自诊断,五年未报信号串扰。

真实使用逻辑:

动态采样:AI通道0.5ms响应,反应釜温度波动实时捕捉;

环境耐受:IP65+宽压,户外光伏逆变器雨天无惧结露。

AEG C921 AS-C921-101|技术规格(四列表格)

参数指标认证标准典型部署方式

信号类型混合I/O(16AI+16AO)ATEX II 2G壁挂安装+防水密封圈

抗干扰能力3级群脉冲+10MHz射频屏蔽UL 61010信号线双层屏蔽+等电位连接

扩展兼容性支持热插拔+最多4扩展单元IEC 61131-2模块化机架+防插错导向槽

能耗控制低功耗模式(<5W待机)ISO 13849 PoE++供电+冗余电源模块

核心优势与性能亮点

化工DCS的“信号绝缘盾”

场景:1500Vrms隔离+自诊断,有毒气体泄漏探测零误报。

轨道交通的“信号定海神针”

工程师实测:抗10g振动,地铁屏蔽门响应延迟<2ms。

冶金炉窑的“省线缆专家”

部署:4~20mA回路供电,热电偶信号传输距离延长至1.2km。

应用场景

火电厂+锅炉联锁:隔离电压→电弧干扰免疫;

半导体+蚀刻机监控:AI高速采样→工艺参数实时调优;

城市轨道交通+屏蔽门控制:IP65→隧道潮湿无惧;

石化平台+紧急停车:ATEX Zone 2→爆炸风险归零;

船舶电力+负载均衡:宽压输入→发电机波动兼容;

食品包装+HACCP监测:热插拔→产线不停机维护;

风电变流器+电流采样:抗射频干扰→并网谐波<3%;

医疗器械+呼吸机控制:低功耗→移动设备续航翻倍;

智能仓储+PLC扩展:EtherNet/IP→AGV队列同步;

1十.核电站+仪控系统:冗余电源→安全壳内零宕机。

安装与维护建议

安装流程:

模块接地端子与设备底座直接连接(规避电位差击穿);

AO通道负载电阻匹配(防止饱和失真);

通过AEG Diagnostics Tool校准AI零点漂移。

易错点提醒:

屏蔽层未双端接地→高频信号衰减;

扩展单元未按顺序上电→通信握手失败。

Part 1:SEO Optimized Title Generation(10 Total)

AEG C921 AS-C921-101 High-density I/O module-32 channels+EtherNet/IP,production line upgrade”vasodilator”!

AEG C921 AS-C921-101|16AI+16AO+isolation protection,chemical DCS”signal insulation shield”!

AEG C921 AS-C921-101-IP65 protection+wide voltage input,outdoor photovoltaic”data lightning rod”!

AEG C921 AS-C921-101:Hot-swap+adaptive sampling,CNC machine tool”zero shutdown magician”!

AEG C921 AS-C921-100-Original compatible+military-grade chip,imported PLC”stop production and life-extending card”!

AEG C921 AS-C921-101|PROFIBUS DP+RS485,the old factory’s transformation of the“communication master key”!

AEG C921 AS-C921-101-ATEX Zone 2+is inherently safe,oil and gas platform”spark fire extinguisher”!

AEG C921 AS-C921-101:Resisting from 10g vibration+anti-RF interference,rail transit”signal stabilizing needle”!

AEG C921 AS-C921-101-Plug and Play+Siemens compatible,the old system”support scalpel”!

AEG C921 AS-C921-101-4~20mA loop power supply,metallurgical instrument”capable cable expert”!

Part 2:Brief description of the product

AEG C921 AS-C921-101:Industrial high-density I/O module,core parameters:32-channel hybrid I/O,communication protocol EtherNet/IP,isolation voltage 1500Vrms.It adopts FPGA dynamic sampling+magnetic isolation technology,passed CE/ATEX certification,and is designed for high-density signal acquisition and harsh environments,covering intelligent manufacturing,energy,rail transit and other fields.

Part 3:Product details

An experienced driver talks about the wild ways of this”signal insulating shield”

A chemical factory has erroneous interlocking due to the failure of the insulation of the original AO module.After replacing the C921 AS-C921-101,it is 1500Vrms isolation+self-diagnosis,and no signal crosstalk has been reported for five years.

Real usage logic:

Dynamic sampling:0.5ms response of AI channel,real-time capture of reactor temperature fluctuations;

Environmental tolerance:IP65+wide pressure,outdoor photovoltaic inverter is not afraid of condensation in rainy days.

AEG C921 AS-C921-101|Technical Specifications(Four Lists)

Parameters Indicators Certification Standard Typical deployment method

Signal type Hybrid I/O(16AI+16AO)ATEX II 2G Wall-mounted installation+waterproof seal

Anti-interference capability:Level 3 group pulse+10MHz radio frequency shielding UL 61010 signal line double-layer shielding+equipotential connection

Extended compatibility Support hot-swap+up to 4 expansion units IEC 61131-2 Modular rack+anti-insert guide slot

Energy consumption control Low power mode(<5W standby)ISO 13849 PoE++power supply+redundant power module

Core advantages and performance highlights

“Signal Insulation Shield”of Chemical DCS

Scenario:1500Vrms isolation+self-diagnosis,zero false alarm detection for toxic gas leakage.

The”signal stabilization needle”of rail transit

Engineer’s actual test:10g vibration resistance,subway shield door response delay is less than 2ms.

“Provincial Cable Expert”of Metallurgical Kiln

Deployment:4~20mA loop power supply,and the thermocouple signal transmission distance is extended to 1.2km.

Application scenarios

Thermal power plant+boiler interlock:isolation voltage→arc interference immunity;

Semiconductor+etching machine monitoring:AI high-speed sampling→real-time tuning of process parameters;

Urban rail transit+shield door control:IP65→Tunnel is wet and fearless;

Petrochemical platform+emergency parking:ATEX Zone 2→Explosion risk is reset to zero;

Ship power+load balancing:wide voltage input→generator fluctuation compatible;

Food packaging+HACCP monitoring:hot-swap→production line does not stop maintenance;

Wind power converter+current sampling:anti-RF interference→grid-connected harmonic<3%;

Medical devices+ventilator control:low power consumption→double the battery life of mobile devices;

Intelligent warehousing+PLC extension:EtherNet/IP→AGV queue synchronization;

10.Nuclear power plant+instrumentation control system:redundant power supply→zero downtime in the containment shell.

Installation and maintenance suggestions

Installation process:

The module grounding terminal is directly connected to the equipment base(avoiding potential difference breakdown);

AO channel load resistance matching(prevent saturation distortion);

Calibrate AI zero-point drift with AEG Diagnostics Tool.

Reminder for easy mistakes:

The shielding layer is not double-end grounded→high-frequency signal attenuation;

The expansion unit does not power on in sequence→Communication handshake failed.