描述

ALPHA SP060S-MF2-20-1C1-2S是一款高性能伺服减速机模块,专为工业自动化领域设计,具备高精度、高稳定性及多功能特性。以下是其核心功能与技术特点的综合概述:

一、产品概述

型号:SP060S-MF2-20-1C1-2S

品牌:ALPHA

系列:阿尔法齿轮系列

定位:高端伺服传动系统核心组件,适用于高精度运动控制场景。

二、核心功能与技术参数

传动性能

-加速扭矩范围:36-5400纳米,支持大扭矩、低转速传动需求。

-减速比灵活性:提供多种配置选项,满足不同传动场景需求。

-高动态响应:标准MF版本适用于高定位精度和动态循环操作,高速MC版本适合连续高速运行。

机械特性

-齿轮设计:采用螺旋齿轮传动,运行噪音低且平稳,减少扭转反弹。

-承载能力:可承受高轴向力和径向力,适用于严苛工况。

-防护等级:IP65,支持任意安装位置,适应复杂工业环境。

可靠性与维护

-润滑系统:终身润滑设计,减少维护频率。

-材料与工艺:高品质材料及精密加工工艺,确保长寿命和高精度。

-兼容性:可与主流伺服电机及控制系统无缝集成,支持标准化接口维护。

三、应用场景

工业机器人:精准定位与高动态运动控制。

数控机床(CNC):提供稳定动力输出,保障加工精度。

自动化生产线:高效传动系统集成,提升生产效率。

精密机械:如伺服转子驱动单元、高精度旋转设备等。

四、设计优势

模块化与集成性

-紧凑型设计,便于快速安装与维护。

-支持三运动设计器(如伺服电机、减速机、驱动器)的优化集成。

扩展灵活性

-多种配置选项可选,满足定制化需求。

-兼容主流工业总线协议,适配复杂系统架构。

五、技术优势

高功率密度:在紧凑体积内实现高效能量传递。

低能耗:最高效率设计,降低系统运行成本。

长寿命:精密制造与润滑技术结合,减少故障率。

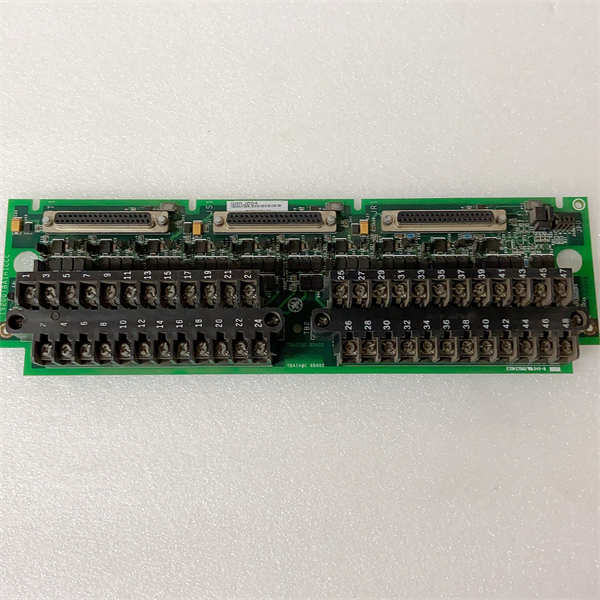

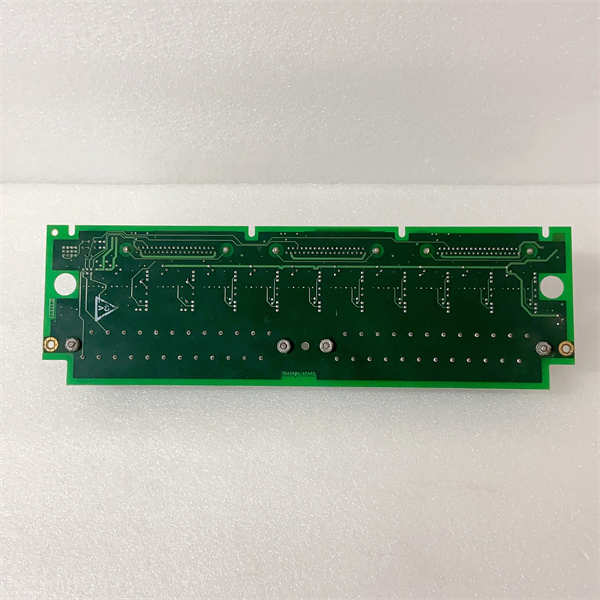

531X121PCRALG1

531X121PCRALG1

ALPHA SP060S-MF2-20-1C1-2S is a high-performance servo reducer module designed for industrial automation with high precision,high stability and multifunctional features.The following is a comprehensive overview of its core functions and technical features:

I.Product Overview

Model:SP060S-MF2-20-1C1-2S

Brand:ALPHA

Series:Alpha Gear Series

Positioning:Core component of high-end servo transmission system,suitable for high-precision motion control scenarios.

II.Core Functions and Technical Parameters

Transmission Performance

-Acceleration torque range:36-5400 nanometers,supporting high torque and low speed transmission requirements.

-Reduction ratio flexibility:Provides a variety of configuration options to meet the needs of different transmission scenarios.

-High dynamic response:The standard MF version is suitable for high positioning accuracy and dynamic cycle operation,and the high-speed MC version is suitable for continuous high-speed operation.

Mechanical characteristics

-Gear design:Adopts helical gear transmission,low and smooth operation noise,and reduces torsional rebound.

-Load capacity:Can withstand high axial and radial forces,suitable for harsh working conditions.

-Protection level:IP65,supports any installation position,adapts to complex industrial environments.

Reliability and maintenance

-Lubrication system:Lifetime lubrication design,reduces maintenance frequency.

-Materials and processes:High-quality materials and precision processing technology to ensure long life and high precision.

-Compatibility:Can be seamlessly integrated with mainstream servo motors and control systems,supports standardized interface maintenance.

III.Application scenarios

Industrial robots:precise positioning and high-dynamic motion control.

CNC machine tools(CNC):Provide stable power output and ensure processing accuracy.

Automated production lines:Efficient transmission system integration to improve production efficiency.

Precision machinery:such as servo rotor drive units,high-precision rotating equipment,etc.

IV.Design advantages

Modularity and integration

-Compact design for quick installation and maintenance.

-Supports optimized integration of three-motion designers(such as servo motors,reducers,and drivers).

Expansion flexibility

-A variety of configuration options are available to meet customized needs.

-Compatible with mainstream industrial bus protocols and adaptable to complex system architectures.

5.Technical advantages

High power density:high efficiency energy transfer in a compact volume.

Low energy consumption:highest efficiency design,reducing system operating costs.

Long life:precision manufacturing combined with lubrication technology to reduce failure rate.