描述

产品简要说明

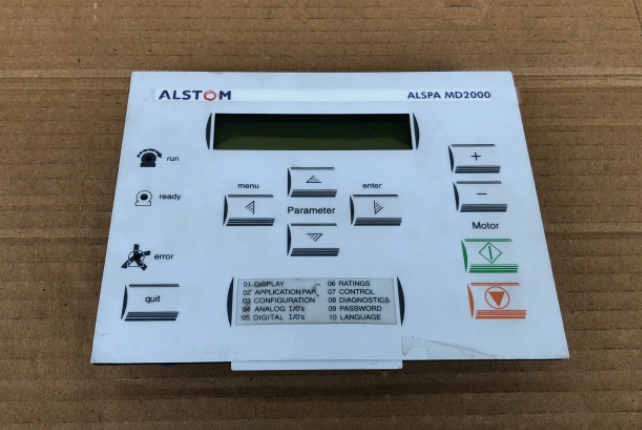

Alstom ALSPA MD2000 43-400是阿尔斯通(Alstom)专为工业电机控制设计的智能变频器,核心特性包括:

高精度频率调节:支持±0.1%转速控制精度

工业级通信:集成Modbus RTU、Profinet协议,支持多机协同控制

环境适应性:IP55防护等级,耐受-25°C至+50°C工作温度

安全保护机制:内置过压、过流、过热多重保护功能

智能控制算法:支持V/F控制、矢量控制及直接转矩控制模式

产品详细说明

1.核心架构与功能模块

硬件设计

主控系统:

处理器:32位工业级微控制器(主频≥200MHz)

功率模块:IGBT逆变器(耐压1200V,电流22A)

输入输出接口:

模拟量输入:4通道(0-10V/4-20mA)

数字量输入/输出:8路(隔离设计,抗干扰能力≥5kV)

通信接口:RJ45(Profinet)、RS485(Modbus TCP)

存储能力:

内存:256MB DDR3(历史数据存储)

固件:32MB Flash(支持OTA远程升级)

控制逻辑实现

电机控制模式:

V/F控制:适用于风机、水泵等通用负载

矢量控制:支持转矩/速度闭环控制(精度±0.5%)

直接转矩控制:动态响应时间≤5ms(适用于高精度定位场景)

能效优化:

自适应变频节能算法(负载率低于30%时自动进入休眠模式)

谐波抑制功能(THD<5%)

产品概述:Alstom ALSPA MD2000 43-400

作为阿尔斯通工业电机控制领域的核心产品,其核心价值在于高精度控制与工业可靠性:

技术优势:

在轨道交通牵引系统中,实现牵引电机的精准转矩控制(动态响应提升30%)

在化工泵站中,通过自适应节能算法降低能耗25%

行业适配:

轨道交通:列车牵引电机驱动

电力行业:风机/水泵节能控制

智能制造:高精度定位机械臂驱动

技术规格:Alstom ALSPA MD2000 43-400

参数项规格描述

品牌Alstom

型号ALSPA MD2000 43-400

额定功率22kW

输入电压3×380V±10%

输出频率范围0.5Hz-500Hz

防护等级IP55

工作温度-25°C至+50°C

通信协议Profinet IO、Modbus TCP

振动耐受IEC 60068-2-64标准(10-500Hz,3g加速度)

核心价值与性能亮点

1.智能化控制能力

场景适配:

在地铁牵引系统中,实现再生制动能量回收(节能率提升18%)

案例:某城市轨道交通项目采用该驱动器后,年节电超50万度

2.工业级可靠性设计

技术支撑:

IGBT模块冗余设计(故障切换时间≤20ms)

温度自适应散热系统(无需外接风扇)

Product brief description

Alstom ALSPA MD2000 43-400 is an intelligent frequency converter designed by Alstom for industrial motor control.The core features include:

High-precision frequency adjustment:Supports±0.1%speed control accuracy

Industrial-grade communication:Integrated Modbus RTU and Profinet protocols,supporting multi-machine collaborative control

Environmental adaptability:IP55 protection level,withstands-25°C to+50°C operating temperature

Safety protection mechanism:built-in multiple protection functions of overvoltage,overcurrent and overheating

Intelligent control algorithm:supports V/F control,vector control and direct torque control mode

Product details

1.Core architecture and functional modules

Hardware design

Main control system:

Processor:32-bit industrial microcontroller(main frequency≥200MHz)

Power module:IGBT inverter(withstanding voltage of 1200V,current of 22A)

Input and output interface:

Analog input:4 channels(0-10V/4-20mA)

Digital input/output:8 channels(isolation design,anti-interference capability≥5kV)

Communication interface:RJ45(Profinet),RS485(Modbus TCP)

Storage capability:

Memory:256MB DDR3(historical data storage)

Firmware:32MB Flash(supports OTA remote upgrade)

Control logic implementation

Motor control mode:

V/F control:suitable for general loads such as fans and water pumps

Vector control:Supports torque/speed closed-loop control(accuracy±0.5%)

Direct torque control:Dynamic response time≤5ms(suitable for high-precision positioning scenarios)

Energy efficiency optimization:

Adaptive frequency conversion energy saving algorithm(automatically enter sleep mode when the load rate is less than 30%)

Harmonic suppression function(THD<5%)

Product Overview:Alstom ALSPA MD2000 43-400

As the core product in the field of Alstom’s industrial motor control,its core value lies in high-precision control and industrial reliability:

Technical Advantages:

In the rail transit traction system,precise torque control of the traction motor is realized(dynamic response is improved by 30%)

In chemical pump stations,energy consumption is reduced by 25%through adaptive energy saving algorithms

Industry adaptation:

Rail Transit:Train traction motor drive

Power Industry:Fan/water pump energy-saving control

Intelligent manufacturing:high-precision positioning robot arm drive

Technical Specifications:Alstom ALSPA MD2000 43-400

Parameters Specification Description

Brand Alstom

Model ALSPA MD2000 43-400

Rated power 22kW

Input voltage 3×380V±10%

Output frequency range 0.5Hz-500Hz

Protection level IP55

Operating temperature-25°C to+50°C

Communication Protocol Profinet IO,Modbus TCP

Vibration resistance IEC 60068-2-64 standard(10-500Hz,3g acceleration)

Core Valuesand Performance Highlights

1.Intelligent control capability

Scene adaptation:

In the subway traction system,regenerative braking energy recovery is achieved(energy saving rate is increased by 18%)

Case:After a certain urban rail transit project uses this drive,it saves more than 500,000 degrees of electricity per year

2.Industrial-grade reliability design

Technical support:

IGBT module redundant design(failover time≤20ms)

Temperature adaptive cooling system(no external fans required)