描述

产品简要说明

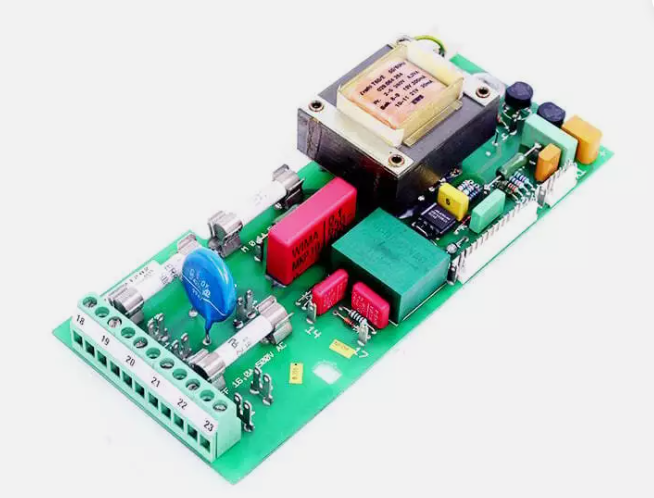

Alstom DFI-150-0003是阿尔斯通(Alstom)专为工业环境设计的火焰检测电路板,核心特性包括:

火焰状态识别:通过实时分析火焰信号,精准判断火焰存在及状态(如燃烧稳定性)

高抗干扰能力:适应-40°C至+85°C极端温度及电磁干扰环境

模块化架构:支持快速安装与维护,兼容PLC、DCS等控制系统

工业级防护:IP66防护等级,防尘防水设计

多场景适配:覆盖焊接、锅炉、燃气轮机等关键工业场景

产品详细说明

1.核心架构与功能模块

硬件设计

传感器接口:

支持多类型火焰传感器(如紫外线、红外传感器)接入

输入信号范围:0-10V(模拟量)

信号处理单元:

采用数字信号处理器(DSP)进行波形分析

噪声抑制算法:消除环境光、电磁干扰对检测精度的影响

通信接口:

模拟量输出:4-20mA电流环(兼容工业仪表)

数字量输出:继电器触点(支持故障报警)

检测逻辑实现

火焰特征分析:

通过傅里叶变换提取火焰频率特性

动态阈值调整:根据环境温度自动校准检测灵敏度

故障诊断:

传感器断线检测:通过电阻测量实现

信号异常报警:支持分级报警(如轻度异常、严重故障)

2.工业级可靠性设计

环境适应性:

温度范围:-40°C至+85°C(符合IEC 61000-6-2标准)

湿度耐受:95%RH(非冷凝)

抗干扰能力:

电磁兼容性(EMC):通过Class IV认证

电源抗扰:支持24V DC宽电压输入(18-36V)

产品概述:Alstom DFI-150-0003

作为阿尔斯通工业安全控制领域的核心组件,其核心价值在于高精度火焰监测与快速响应:

技术优势:

在燃气轮机点火控制中,误报率≤0.1%(典型工况)

在焊接设备中,火焰熄灭响应时间≤50ms

行业适配:

能源电力:锅炉燃烧监控、燃气轮机点火控制

金属加工:焊接机器人火焰检测、切割设备安全联锁

化工制造:反应炉火焰状态分析、紧急停机保护

Product brief description

Alstom DFI-150-0003 is a flame detection circuit board designed by Alstom for industrial environments,with core features including:

Flame state recognition:By analyzing the flame signal in real time,accurately determine the existence and state of the flame(such as combustion stability)

High anti-interference ability:adapt to extreme temperatures of-40°C to+85°C and electromagnetic interference environment

Modular architecture:supports rapid installation and maintenance,compatible with PLC,DCS and other control systems

Industrial protection:IP66 protection level,dustproof and waterproof design

Multi-scene adaptation:covering key industrial scenarios such as welding,boilers,and gas turbines

Product details

1.Core architecture and functional modules

Hardware design

Sensor interface:

Supports access to multiple types of flame sensors(such as ultraviolet and infrared sensors)

Input signal range:0-10V(analog quantity)

Signal processing unit:

Waveform analysis using digital signal processor(DSP)

Noise suppression algorithm:Eliminate the influence of ambient light and electromagnetic interference on detection accuracy

Communication interface:

Analog output:4-20mA current loop(compatible with industrial instruments)

Digital output:relay contact(supports fault alarm)

Detection logic implementation

Flame characteristics analysis:

Extract flame frequency characteristics by Fourier transform

Dynamic threshold adjustment:Automatic calibration of detection sensitivity based on ambient temperature

Troubleshooting:

Sensor disconnection detection:realized through resistance measurement

Signal abnormality alarm:Supports graded alarms(such as mild abnormality,serious fault)

2.Industrial-grade reliability design

Environmental adaptability:

Temperature range:-40°C to+85°C(compliant with IEC 61000-6-2 standard)

Humidity tolerance:95%RH(non-condensing)

Anti-interference ability:

Electromagnetic compatibility(EMC):passed Class IV certification

Power supply immunity:Supports 24V DC wide voltage input(18-36V)

Product Overview:Alstom DFI-150-0003

As the core component of Alstom’s industrial safety control field,its core value lies in high-precision flame monitoring and rapid response:

Technical Advantages:

In gas turbine ignition control,the false alarm rate is≤0.1%(typical working conditions)

In welding equipment,the flame extinguishing response time is≤50ms

Industry adaptation:

Energy and electricity:boiler combustion monitoring,gas turbine ignition control

Metal processing:Flame detection of welding robots,safety interlocking of cutting equipment

Chemical manufacturing:reaction furnace flame state analysis,emergency shutdown protection