描述

产品简要说明

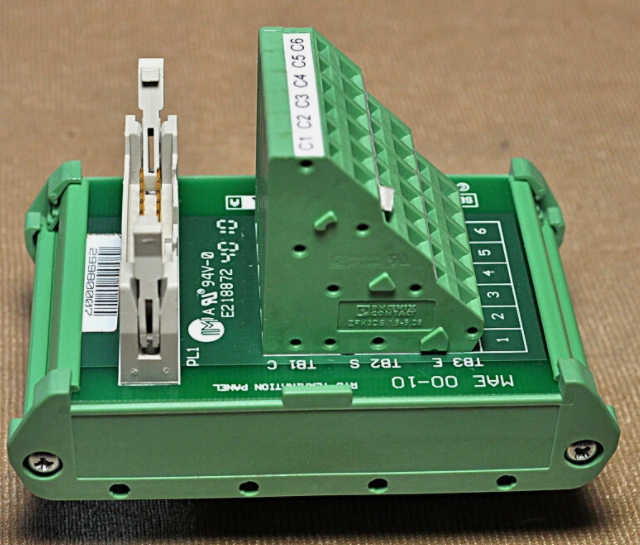

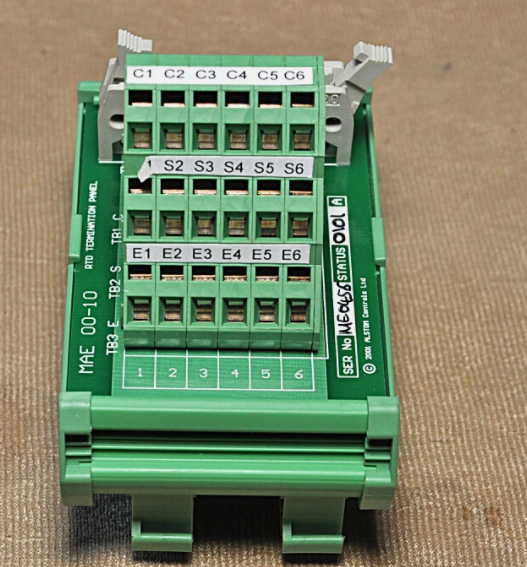

Alstom Mae00-10 RTD是阿尔斯通(Alstom)专为工业环境设计的高精度铂热电阻温度传感器,核心特性包括:

高精度测温:支持±0.1℃精度(-200℃至+850℃范围)

工业级通信:集成IO-Link协议,支持远程配置与诊断

环境适应性:IP67防护等级,耐受-40℃至+125℃极端温度

抗干扰设计:四线制结构,消除导线电阻误差

模块化扩展:兼容多通道信号采集系统

产品详细说明

1.核心架构与功能模块

硬件设计

传感器类型:

材质:铂(Pt100/Pt1000可选)

结构:四线制(两根激励线+两根测量线)

信号处理单元:

激励电流:1-5mA可调(通过IO-Link远程配置)

信号调理:集成模拟前端(AFE)芯片(如AD7124-4),支持Σ-ΔADC转换

通信接口:

主接口:IO-Link 3线制(支持过程数据、诊断数据传输)

辅助接口:RS485(兼容Modbus RTU协议)

信号处理流程

激励电流生成:由AFE芯片提供稳定电流,驱动铂电阻产生电压信号。

信号放大与滤波:采用可编程增益放大器(PGA)放大微弱信号,并通过数字滤波消除噪声。

非线性补偿:内置多项式拟合算法,修正铂电阻的温度-电阻曲线非线性误差。

数据输出:通过IO-Link接口传输数字温度值及诊断信息(如传感器状态、校准数据)。

2.工业级通信与扩展性

IO-Link优势:

远程配置:支持阈值设置、采样率调整等参数修改

诊断功能:实时监测传感器故障(如断线、超温报警)

数据兼容性:与SCADA系统、PLC无缝对接(如西门子S7-1500)

多场景适配:

单点测量:直接连接变送器或控制器

多通道集成:通过IO-Link主站扩展至32通道,适用于大型设备温度场监测

产品概述:Alstom Mae00-10 RTD

作为阿尔斯通工业测温领域的旗舰产品,其核心价值在于高精度与智能化:

技术优势:

在核电站反应堆冷却剂监测中,实现±0.05℃的长期稳定性

在轨道交通牵引电机绕组温度控制中,故障响应时间≤50ms

行业适配:

能源电力:锅炉壁温、变压器绕组温度监测

轨道交通:列车牵引系统、制动电阻温度控制

石油化工:反应器温度场均匀性分析

Product brief description

The Alstom Mae00-10 RTD is a high-precision platinum thermal resistance temperature sensor designed by Alstom for industrial environments,with core features including:

High-precision temperature measurement:Supports±0.1℃accuracy(-200℃to+850℃range)

Industrial-grade communication:Integrated IO-Link protocol,supporting remote configuration and diagnostics

Environmental adaptability:IP67 protection level,withstand extreme temperatures of-40℃to+125℃

Anti-interference design:four-wire structure to eliminate wire resistance errors

Modular expansion:compatible with multi-channel signal acquisition system

Product details

1.Core architecture and functional modules

Hardware design

Sensor type:

Material:Platinum(Pt100/Pt1000 optional)

Structure:four-wire system(two excitation lines+two measurement lines)

Signal processing unit:

Excitation current:1-5mA adjustable(remote configuration via IO-Link)

Signal conditioning:Integrated analog front-end(AFE)chip(such as AD7124-4),supportsΣ-ΔADC conversion

Communication interface:

Main interface:IO-Link 3-wire system(supports process data and diagnostic data transmission)

Auxiliary interface:RS485(compatible with Modbus RTU protocol)

Signal processing flow

Excitation current generation:The AFE chip provides a stable current and drives the platinum resistor to generate a voltage signal.

Signal amplification and filtering:Use a programmable gain amplifier(PGA)to amplify weak signals and eliminate noise through digital filtering.

Nonlinear compensation:built-in polynomial fitting algorithm to correct the nonlinear error of the temperature-resistance curve of the platinum resistor.

Data output:Transfer digital temperature valuesand diagnostic information(such as sensor status,calibration data)through the IO-Link interface.

2.Industrial-grade communication and scalability

IO-Link Advantages:

Remote configuration:Supports parameter modification such as threshold setting,sampling rate adjustment,etc.

Diagnostic function:Real-time monitoring of sensor failures(such as disconnection,overtemperature alarm)

Data compatibility:seamless connection with SCADA systems and PLCs(such as Siemens S7-1500)

Multi-scene adaptation:

Single point measurement:Direct connection to the transmitter or controller

Multi-channel integration:Extended to 32 channels through IO-Link master,suitable for temperature field monitoring of large equipment

Product Overview:Alstom Mae00-10 RTD

As Alstom’s flagship product in the field of temperature measurement,its core value lies in high precision and intelligence:

Technical Advantages:

In the monitoring of reactor coolant in nuclear power plant,long-term stability of±0.05℃is achieved

In the temperature control of rail transit traction motor winding,the fault response time is≤50ms

Industry adaptation:

Energy and electricity:Boiler wall temperature,transformer winding temperature monitoring

Rail Transit:Train traction system,brake resistance temperature control

Petrochemical:Reactor temperature field uniformity analysis