描述

产品简要说明

ALSTOM MX3EG1A.72是阿尔斯通(Alstom)专为电力系统并网设计的高精度自动同步控制器,核心特性包括:

双模式并网控制:支持带电母线/不带电母线自动切换(响应时间≤200ms)

多参数校准:

最大电压偏差±5%(母线电压/额定电压)

最大频率偏差±2Hz(额定频率/母线频率)

智能诊断系统:

记录8次事件日志(含时间、电压/频率值、相差等)

实时监测输出继电器状态(18个逻辑状态采样)

多协议通信:

LONWORKS总线(远程监控)

MODBUS RS485(本地配置)

双设置组管理:支持主/备参数组快速切换

产品详细说明

1.核心控制逻辑

并网顺序起动

预同步流程:

检测母线电压(Ubn)与发电机电压(Ugn)有效值(Ubn倍数表示)

校验频率差(Δf)与相差(Δφ)

启动调压器(最低发电机电压阈值:Ugn×0.7)

触发并网命令(最大尝试次数可设)

调压器与频率稳定器

电压控制阈值:

最大电压差:Ubn±10%

最低发电机电压:Ugn×0.7

频率稳定参数:

最大频率偏差:±2Hz(母线/发电机)

最大频率差:±0.5Hz

备用母线模式

三种工作状态:

OFF:仅主母线控制

ON:备用母线实时同步

ON-CHECK:备用母线状态预检(相差校准)

2.智能运维系统

诊断与记录:

事件日志:存储最后8次并网事件(含时间、电压/频率值、相差、尝试次数)

计数器:累计并网成功/失败次数

RCE记录:32次状态变化(需PC或网络读取)

示波扰动分析:

2.5秒瞬时值记录(每周期12次采样)

包含电压/频率波形与数字输入状态

3.人机交互设计

LCD菜单结构:

主读数菜单:实时显示电压/频率值、相差、输出继电器状态

主设置菜单:

参数组切换(主/备)

语言选择(中/英/西)

日期/时间校准

测试菜单:

继电器自检

通信协议模拟

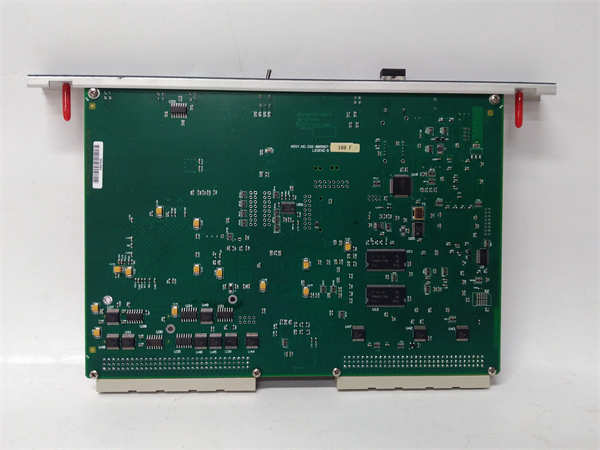

DS200KLDBG1ABC

DS200KLDBG1ABC

Product brief description

ALSTOM MX3EG1A.72 is a high-precision automatic synchronization controller designed by Alstom for grid connection to power systems.The core features include:

Dual mode grid-connected control:supports automatic switching of live bus/unrelease bus(response time≤200ms)

Multi-parameter calibration:

Maximum voltage deviation±5%(bus voltage/rated voltage)

Maximum frequency deviation±2Hz(rated frequency/bus frequency)

Intelligent diagnostic system:

Record 8 event logs(including time,voltage/frequency value,phase difference,etc.)

Real-time monitoring of output relay status(18 logical state samples)

Multi-protocol communication:

LONWORKS bus(remote monitoring)

MODBUS RS485(local configuration)

Dual-set group management:supports quick switching of primary/secure parameter groups

Product details

1.Core control logic

Start the grid connection sequence

Pre-synchronization process:

Detect bus voltage(Ubn)and generator voltage(Ugn)effective value(denoted by Ubn multiple)

Verification frequency difference(Δf)and phase difference(Δφ)

Start the voltage regulator(minimum generator voltage threshold:Ugn×0.7)

Trigger the grid connection command(maximum number of attempts can be set)

Voltage regulator and frequency stabilizer

Voltage control threshold:

Maximum voltage difference:Ubn±10%

Minimum generator voltage:Ugn×0.7

Frequency stability parameters:

Maximum frequency deviation:±2Hz(busbar/generator)

Maximum frequency difference:±0.5Hz

Alternate bus mode

Three working states:

OFF:Only the master busbar control

ON:Real-time synchronization of backup bus

ON-CHECK:backup bus status pre-check(phase difference calibration)

2.Intelligent operation and maintenance system

Diagnosis and Recording:

Event log:Store the last 8 grid-connected events(including time,voltage/frequency value,phase difference,number of attempts)

Counter:cumulative number of successful/failed connections

RCE record:32 state changes(requires PC or network reading)

Oscillo-perturbation analysis:

2.5 seconds instantaneous value record(12 samples per cycle)

Includes voltage/frequency waveform and digital input state

3.Human-computer interaction design

LCD menu structure:

Main reading menu:Real-time display of voltage/frequency value,phase difference,output relay status

Main Settings Menu:

Parameter group switching(main/standby)

Language selection(Chinese/English/Western)

Date/time calibration

Test menu:

Relay self-test

Communication protocol simulation