描述

1.高压电气控制与保护

过流/过压/欠压保护:

集成智能断路器,可设置多级保护阈值(如过流保护分快速动作(≤2ms)和延时动作(10-100ms),避免误触发)。

过压保护响应时间≤5ms,欠压保护响应时间≤10ms,支持AC/DC系统的电压波动监测。

高压隔离与分断:

采用真空断路器或气密式接触器,支持手动/远程分断,分断能力≥50kA(AC 25kV),满足极端故障切断需求。

隔离电阻≥1GΩ(5000V DC测试),确保维护时人员安全。

短路保护:

集成熔断器+电子保护双冗余设计,熔断器熔断后可通过LED指示灯+通信接口同时报警,便于快速定位故障。

2.信号监测与诊断

多参数监测:

实时采集电流、电压、温度、接触器状态等数据,支持模拟量输出(AO)和数字量输出(DO),可连接至列车监控系统(TCMS)。

部分型号可能集成振动传感器,监测设备运行中的机械应力,预防接触器触点松动。

自诊断与预测性维护:

内置微处理器(MCU),通过算法分析电流波形、温度变化趋势,提前预测元件寿命(如熔断器剩余寿命、接触器触点磨损度)。

支持故障代码存储(≥100条)和黑匣子功能,记录故障发生时的电气参数,辅助事后分析。

3.通信与网络集成

多协议兼容:

支持CAN总线、MVB(多功能车辆总线)、以太网(TCP/IP),可无缝接入不同厂商的列车网络系统。

部分型号可能集成无线通信模块(如Wi-Fi/LTE),支持远程配置与诊断(如通过地面服务器更新保护参数)。

列车网络集成:

作为牵引控制单元(PCU)或辅助电源控制单元(APCU)的子模块,通过过程数据对象(PDO)与主控制器交换关键信息(如受电弓状态、牵引电机电流)。

4.环境适应性增强

宽温与防护:

工作温度范围-55℃~+95℃,较前代(如N897164610L的-50℃~+90℃)进一步扩展,适应北极圈高寒或中东高温沙漠环境。

防护等级IP68(防尘防水),可短期浸水(如通过积水路段)而不损坏。

抗振动与冲击:

通过IEC 61373 Category 3 Class B认证(前代为Category 2 Class A),可承受更高频率(5-500Hz)和更大加速度(10g)的振动,满足磁悬浮列车或重载铁路需求。

电磁兼容(EMC):

符合EN 50121-4标准,抗接触网电弧、牵引电机谐波、无线通信干扰,确保信号传输稳定性。

5.模块化与可扩展性

标准化接口:

采用ISO标准高压接头、螺纹连接或快插式接口,支持热插拔,便于快速更换或扩展功能(如增加通信模块或传感器)。

功能扩展选项:

可选配能量计量模块(测量牵引系统能耗)、接地故障检测模块(监测对地绝缘电阻),适应不同客户定制需求。

关键技术参数

1.电气参数

参数典型值说明

额定电压DC 750V/1500V/3000V

AC 25kV/50kV覆盖地铁(DC 1500V)和高铁(AC 25kV)需求

额定电流800A-4000A(持续)牵引系统用元件电流更高

短路分断能力≥80kA(AC 25kV系统)适应重载铁路或高速列车的极端故障

绝缘电阻≥1GΩ(5000V DC测试)高压环境下的安全保障

介电强度15kV AC/1min(线间)验证高压绝缘性能

响应时间≤1.5ms(过流保护)比前代更快,减少设备损伤风险

保护动作时间≤3ms(过压/欠压保护)快速响应电压异常

2.机械参数

参数典型值说明

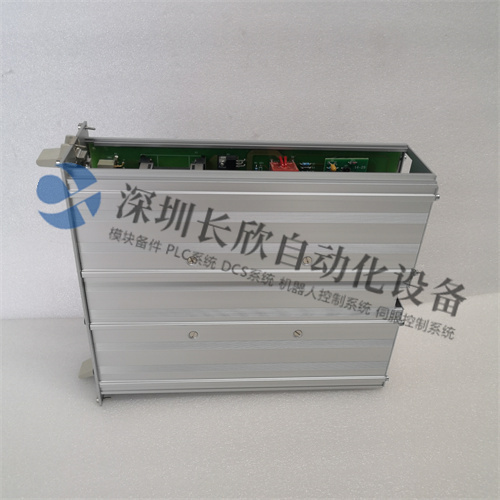

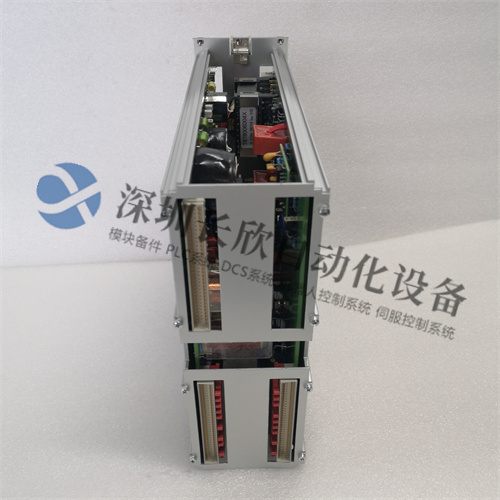

尺寸320mm×220mm×130mm(长×宽×高)紧凑设计,节省高压柜安装空间

重量≤7.2kg铝合金外壳+工程塑料,轻量化

安装方式面板安装/导轨安装/DIN rail安装灵活适配不同高压设备布局

振动等级IEC 61373 Category 3 Class B满足磁悬浮列车或重载铁路振动标准

冲击耐受100g(11ms半正弦波)适应列车碰撞等极端冲击

1.High voltage electrical control and protection

Overcurrent/overvoltage/undervoltage protection:

Integrated intelligent circuit breaker,multi-level protection threshold can be set(such as overcurrent protection divided into fast action(≤2ms)and delay action(10-100ms)to avoid false triggering).

Overvoltage protection response time≤5ms,undervoltage protection response time≤10ms,supports voltage fluctuation monitoring of AC/DC system.

High voltage isolation and disconnection:

It adopts a vacuum circuit breaker or air-tight contactor,supports manual/remote disconnection,with a breaking capacity of≥50kA(AC 25kV),meeting the extreme fail-off needs.

Isolation resistance≥1GΩ(5000V DC test)to ensure personnel safety during maintenance.

Short circuit protection:

Integrated fuse+electronic protection dual redundant design,after the fuse is fuse,it can alarm simultaneously through the LED indicator+communication interface,which facilitates rapid positioning of faults.

2.Signal monitoring and diagnosis

Multi-parameter monitoring:

Real-time acquisition of current,voltage,temperature,contactor status and other data,supports analog output(AO)and digital output(DO),and can be connected to the train monitoring system(TCMS).

Some models may integrate vibration sensors to monitor mechanical stress during operation of the equipment and prevent contacts from loosening.

Self-diagnosis and predictive maintenance:

Built-in microprocessor(MCU)analyzes current waveforms and temperature changes through algorithms,and predicts component life(such as the remaining life of the fuse and the wear of contactor contacts)in advance.

Supports fault code storage(≥100 items)and black box functions,record electrical parameters when the fault occurs,and assists in post-event analysis.

3.Communication and network integration

Multi-protocol compatible:

Supports CAN bus,MVB(multi-function vehicle bus),and Ethernet(TCP/IP),and can seamlessly connect to train network systems of different manufacturers.

Some models may integrate wireless communication modules(such as Wi-Fi/LTE)and support remote configuration and diagnosis(such as updating protection parameters through terrestrial servers).

Train network integration:

As a submodule of the traction control unit(PCU)or auxiliary power control unit(APCU),key information(such as pantograph status,traction motor current)is exchanged with the main controller through the process data object(PDO).

4.Enhanced environmental adaptability

Wide temperature and protection:

The operating temperature range is-55℃~+95℃,which is further expanded from previous generations(such as-50℃~+90℃of N897164610L),adapting to the Arctic Circle or the Middle East high-temperature desert environment.

Protection level IP68(dust-proof and waterproof),can be immersed in water for a short period of time(such as through water-stabilized sections)without damage.

Vibration and shock resistance:

IEC 61373 Category 3 Class B certification(previously Category 2 Class A),can withstand vibrations at higher frequencies(5-500Hz)and greater acceleration(10g),meeting the needs of maglev trains or heavy-duty railways.

Electromagnetic compatibility(EMC):

Comply with EN 50121-4 standards,resist contact grid arc,traction motor harmonics,wireless communication interference,and ensure signal transmission stability.

5.Modularity and scalability

Standardized interface:

It adopts ISO standard high-voltage connectors,threaded connections or fast plug-in interfaces,and supports hot plug-in,which facilitates quick replacement or expansion of functions(such as adding communication modules or sensors).

Feature extension options:

Optional energy metering module(measures the energy consumption of the traction system)and ground fault detection module(monitors ground insulation resistance)can be used to meet different customer custom needs.

3.Key technical parameters

1.Electrical parameters

Parameters Typical Description

Rated voltage DC 750V/1500V/3000V

AC 25kV/50kV covers subway(DC 1500V)and high-speed rail(AC 25kV)requirements

Rated current 800A-4000A(continuous)The components for traction systems are higher

Short circuit breaking capability≥80kA(AC 25kV system)To adapt to extreme failures of heavy-duty railways or high-speed trains

Insulation resistance≥1GΩ(5000V DC test)Safety guarantee in high voltage environment

Dielectric strength 15kV AC/1min(between lines)Verify high voltage insulation performance

Response time≤1.5ms(overcurrent protection)Faster than previous generations,reducing the risk of equipment damage

Protection operation time≤3ms(overvoltage/undervoltage protection)Quick response to voltage abnormality

2.Mechanical parameters

Parameters Typical Description

Dimensions:320mm×220mm×130mm(Length×Width×Height)Compact design,saving high-voltage cabinet installation space

Weight≤7.2kg Aluminum alloy shell+engineering plastic,lightweight

Installation method Panel installation/rail installation/DIN rail installation Flexible adaptation to different high-voltage equipment layouts

Vibration level IEC 61373 Category 3 Class B Meets the vibration standards of magnetic levitation trains or heavy-duty railways

Impact tolerance 100g(11ms semi-sine wave)to adapt to extreme impacts such as train collisions

ABB 型号:GBU72 3BHE055094R0002 型号:3BHE055094R0002 GBU72 型号:GBU72 型号:3BHE055094R0002 型号:3BHE031197R0001 型号:3BHB030310R0001 型号:73BHE055094R0002 GBU72 型号:73BHE055094R0002 型号:GBU72 型号:ABB PCS6000 PRODUCT FAMLIY