描述

产品简要说明

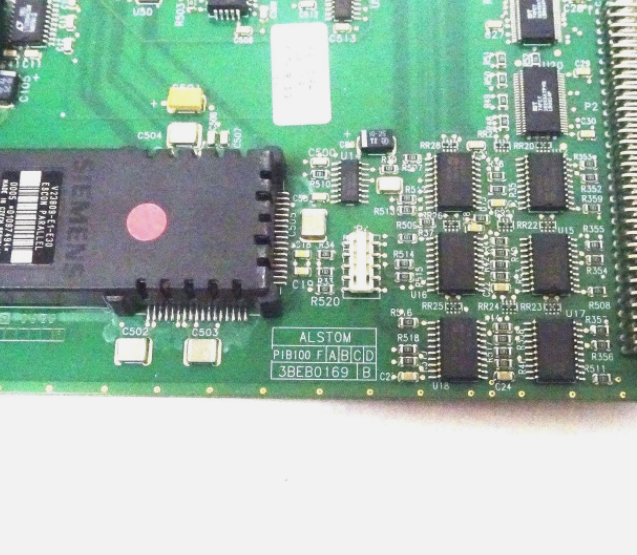

ALSTOM PIB100 F 3BEB0169 BOARD是阿尔斯通(ALSTOM)旗下CONVERTEAM系列的工业级印刷电路板(PCB)模块,核心特性包括:

功能定位:专为信号处理、接口转换及控制逻辑设计

工业兼容性:支持Modbus、Profibus等工业通信协议

环境适应性:工业级防护等级(IP20或更高),工作温度范围-20°C~+70°C

扩展能力:支持DIN导轨安装,兼容ALSTOM/CONVERTEAM系统

产品详细说明

1.硬件架构与核心功能

模块类型

PCB设计:多层高密度布线,支持高频信号传输(最高100MHz)

功能分区:

信号处理单元:集成ADC/DAC芯片,支持16位模拟信号转换

通信接口:双路RS485、以太网(10/100Mbps)及数字I/O通道

电源管理:冗余24V DC输入,支持宽电压范围(18-30V DC)

安全机制

过压/过流保护:实时监测并切断异常电流

温度监控:内置热敏电阻,超温自动降频或关机

产品概述:ALSTOM PIB100 F 3BEB0169 BOARD

作为工业自动化系统的核心组件,其核心价值体现在高可靠性与系统集成能力:

技术价值:

在变电站自动化中实现微秒级信号响应

在工业过程控制中支持多协议混合组网

行业适配:

能源电力:发电机组控制、电网监测

智能制造:数控机床信号调理、机器人运动控制

轨道交通:地铁信号系统、牵引设备控制

技术规格:ALSTOM PIB100 F 3BEB0169 BOARD

参数项规格描述

模块类型工业级PCB模块

接口类型RS485(双通道)、以太网(RJ45)、数字I/O(24点DI/DO)

工作电压24V DC(18-30V DC输入范围)

工作温度-20°C~+70°C

防护等级IP20(可选IP65防护套件)

通信协议Modbus RTU、Profibus DP、EtherNet/IP

核心价值与性能亮点

1.工业级可靠性设计

技术优势:

通过IEC 61000-4-2 8kV静电测试

冗余电源输入(支持双路24V DC)

应用案例:某变电站模块连续运行8年无故障

2.多协议兼容性

技术优势:

支持Modbus RTU/Profibus DP/EtherNet/IP三协议动态切换

协议栈固件可在线升级

价值体现:某风电场实现PLC与SCADA系统的无缝对接

Product brief description

ALSTOM PIB100 F 3BEB0169 BOARD is an industrial-grade printed circuit board(PCB)module of the CONVERTEAM series under ALSTOM.The core features include:

Functional positioning:specially designed for signal processing,interface conversion and control logic

Industrial compatibility:Supports industrial communication protocols such as Modbus and Profibus

Environmental adaptability:industrial protection grade(IP20 or higher),operating temperature range-20°C~+70°C

Extended capability:Support DIN rail installation,compatible with ALSTOM/CONVERTEAM system

Product details

1.Hardware architecture and core functions

Module Type

PCB design:multi-layer high-density wiring,supporting high-frequency signal transmission(up to 100MHz)

Functional partition:

Signal processing unit:integrated ADC/DAC chip,supports 16-bit analog signal conversion

Communication interface:dual-channel RS485,Ethernet(10/100Mbps)and digital I/O channels

Power management:Redundant 24V DC input,support wide voltage range(18-30V DC)

Security mechanism

Overvoltage/overcurrent protection:Real-time monitoring and cutting off abnormal current

Temperature monitoring:built-in thermistor,automatic frequency reduction or shutdown of over-temperature

Product Overview:ALSTOM PIB100 F 3BEB0169 BOARD

As the core component of industrial automation systems,its core value is reflected in high reliability and system integration capabilities:

Technical value:

Implement microsecond signal response in substation automation

Support multi-protocol hybrid networking in industrial process control

Industry adaptation:

Energy and electricity:generator set control,grid monitoring

Intelligent manufacturing:CNC machine tool signal conditioning,robot motion control

Rail Transit:Subway signal system,traction equipment control

Technical Specifications:ALSTOM PIB100 F 3BEB0169 BOARD

Parameters Specification Description

Module type Industrial grade PCB module

Interface type RS485(dual channel),Ethernet(RJ45),digital I/O(24-point DI/DO)

Operating voltage 24V DC(18-30V DC input range)

Working temperature-20°C~+70°C

Protection level IP20(optional IP65 protection kit)

Communication protocols Modbus RTU,Profibus DP,EtherNet/IP

Core Valuesand Performance Highlights

1.Industrial-grade reliability design

Technical Advantages:

Passed IEC 61000-4-2 8kV electrostatic test

Redundant power input(supports dual 24V DC)

Application case:A substation module operates continuously for 8 years without any trouble

2.Multi-protocol compatibility

Technical Advantages:

Supports dynamic switching of Modbus RTU/Profibus DP/EtherNet/IP protocols

Protocol stack firmware can be upgraded online

Value manifestation:A wind farm realizes seamless connection between PLC and SCADA system