描述

一、产品概述

AMAT COMPONENT SIDE是泛林集团(Applied Materials,Inc.)半导体制造设备中的核心功能组件,通常指设备中直接参与工艺过程的结构部件(如腔体、基座、传感器支架等)。其设计需满足高真空、高温、腐蚀性气体等严苛环境要求,适用于薄膜沉积、刻蚀、离子注入等工艺。

二、核心参数与性能

物理特性

材料:

主体结构:钛合金(如Ti-6Al-4V)或不锈钢(316L),耐高温及腐蚀。

表面处理:阳极氧化或化学气相沉积(CVD)涂层,防止污染。

尺寸:

典型腔体直径:200mm(8英寸)至300mm(12英寸)晶圆兼容设计。

厚度/高度:根据功能定制(如基座厚度50-150mm)。

工艺适应性

真空环境:

极限真空度:≤1×10⁻⁶Torr(依赖设备类型)。

泄漏率:≤1×10⁻⁸Torr·L/s(氦质谱检测)。

温度控制:

工作温度范围:-150°C至1200°C(如热电偶基座)。

升温速率:5°C/min(均匀性±2°C)。

接口与兼容性

机械接口:

真空法兰标准:ISO-KF 25/50/100(根据尺寸)。

电气接口:屏蔽电缆(RG405/RG406),抗电磁干扰。

工艺气体兼容性:

支持Ar、Cl₂、SF₆、NF₃等腐蚀性气体。

抗气体渗透性:表面涂层耐压≥1000 bar·cm。

功能特性

定位精度:

基座定位误差:≤5μm(重复性±1μm)。

传感器安装面平面度:≤0.5μm(Ra≤0.1μm)。

动态性能:

振动隔离:频率范围20Hz-20kHz,衰减≥40dB。

三、应用场景

薄膜沉积设备

作为靶材基座或衬底托盘,支撑PVD/CVD工艺。

干法刻蚀设备

作为反应腔体侧壁,承受等离子体轰击。

离子注入机

作为静电吸盘或偏转板,控制离子束路径。

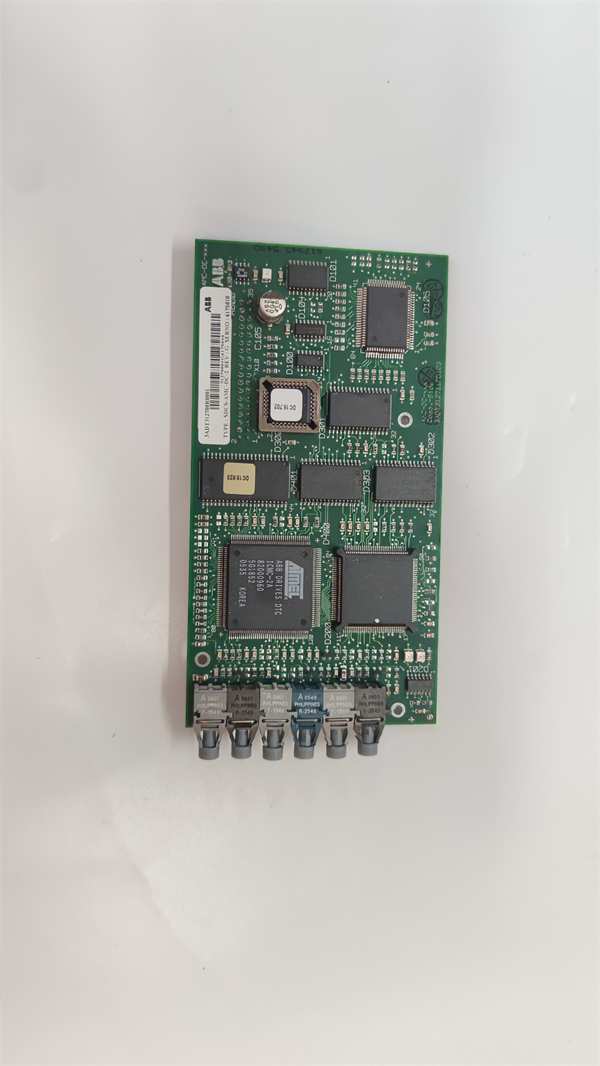

IS210SAMBH2AA

IS210SAMBH2AA

1.Product Overview

AMAT COMPONENT SIDE is the core functional component in the semiconductor manufacturing equipment of Applied Materials,Inc.,and usually refers to structural components directly involved in the process of the equipment(such as cavity,base,sensor bracket,etc.).Its design needs to meet the strict environmental requirements such as high vacuum,high temperature,corrosive gases,and is suitable for thin film deposition,etching,ion implantation and other processes.

2.Core parameters and performance

Physical characteristics

Material:

Main structure:titanium alloy(such as Ti-6Al-4V)or stainless steel(316L),resistant to high temperature and corrosion.

Surface treatment:Anodized or chemical vapor deposition(CVD)coating to prevent contamination.

size:

Typical cavity diameter:200mm(8 inches)to 300mm(12 inches)wafer compatible design.

Thickness/height:Customized according to the function(such as base thickness 50-150mm).

Process adaptability

Vacuum environment:

Extreme vacuum degree:≤1×10⁻⁶Torr(depending on device type).

Leakage rate:≤1×10⁻⁸Torr·L/s(helium mass spectrometry detection).

Temperature control:

Operating temperature range:-150°C to 1200°C(such as thermocouple base).

Warming rate:5°C/min(uniformity±2°C).

Interface and compatibility

Mechanical interface:

Vacuum flange standard:ISO-KF 25/50/100(depending on size).

Electrical interface:shielded cable(RG405/RG406),anti-electromagnetic interference.

Process gas compatibility:

Supports corrosive gases such as Ar,Cl₂,SF₆,NF₃.

Gas permeability:The pressure resistance of the surface coating is≥1000 bar·cm.

Functional Features

Positioning accuracy:

Base positioning error:≤5μm(repeatability±1μm).

The flatness of the sensor installation surface:≤0.5μm(Ra≤0.1μm).

Dynamic performance:

Vibration isolation:frequency range 20Hz-20kHz,attenuation≥40dB.

III.Application scenarios

Thin film deposition equipment

As a target base or substrate tray,the PVD/CVD process is supported.

Dry etching equipment

As the side wall of the reaction chamber,it withstands plasma bombardment.

Ion implanter

As an electrostatic suction cup or deflection plate,the ion beam path is controlled.