描述

产品简要说明

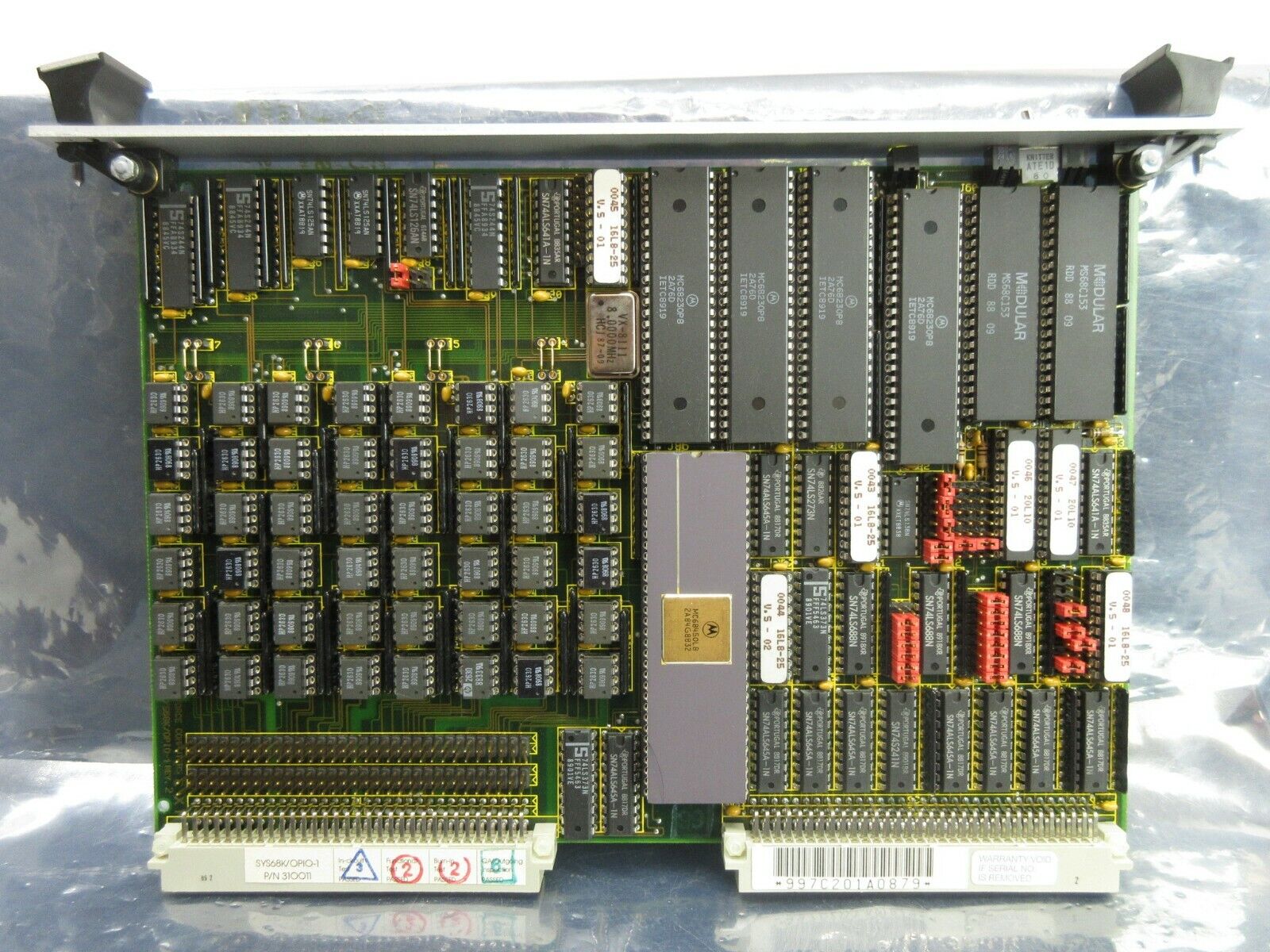

ASML 4022.428.1134是ASML PAS 5000/2500系列步进式光刻机的核心气动控制模块,专为200mm晶圆的精密定位与传输设计。其核心功能包括:

动态压力调节:支持0-10bar压力范围,响应时间≤10ms。

多轴协同控制:集成4通道独立气缸驱动,定位精度达±0.1μm。

故障自检系统:实时监测气压波动,误报率≤0.01%。

产品详细说明

1.技术架构与创新

气动执行系统:

多级节流阀:采用Festo气动阀组,实现压力梯度控制。

柔性连接设计:硅胶波纹管密封,抗振动能力≥10g。

智能控制逻辑:

PID闭环算法:结合温度补偿模块,环境温度波动±10℃时仍保持精度。

冗余保护机制:双传感器交叉验证,单点故障不影响整体功能。

2.工艺适配性

光刻流程应用:

晶圆对准:配合步进台实现±0.5μm套准精度。

掩膜板定位:支持0.5mm行程范围内±0.05μm重复定位。

维护兼容性:

模块化接口:与ASML 4022.428.05412 Kay阀组兼容,支持快速更换。

诊断接口:通过VME总线输出状态数据,适配ASML RadiSys控制系统。

技术规格:ASML 4022.428.1134

参数项规格描述

工作压力范围0-10bar

定位精度±0.1μm(静态);±0.3μm(动态)

响应时间≤10ms(压力阶跃响应)

环境温度-20℃至60℃

核心价值与性能亮点

1.高可靠性设计

抗污染能力:硅胶密封结构可耐受0.1μm级颗粒污染,寿命≥5000万次循环。

低维护成本:模块化设计使单次维修时间缩短至2小时。

2.工艺兼容性

多制程适配:支持i线(365nm)、KrF(248nm)光刻工艺切换。

动态补偿:温度漂移补偿算法使长期稳定性提升40%。

应对挑战,创造价值

1.高精度定位难题

技术突破:多轴同步控制算法+柔性连接设计,实现晶圆台抖动<0.01μm。

应用案例:某存储器厂部署后,关键层缺陷密度降低30%。

2.复杂环境适应性

技术突破:宽温域密封结构+抗电磁干扰设计,满足洁净室Class 1环境要求。

应用案例:某逻辑芯片厂在湿度40%-60%环境下连续运行3年无故障。

Product brief description

ASML 4022.428.1134 is the core pneumatic control module of ASML PAS 5000/2500 series stepper lithography machines,designed for precision positioning and transmission of 200mm wafers.Its core functions include:

Dynamic pressure adjustment:supports the pressure range of 0-10bar,and the response time is≤10ms.

Multi-axis collaborative control:integrated 4-channel independent cylinder drive,positioning accuracy up to±0.1μm.

Fault self-test system:monitor air pressure fluctuations in real time,false alarm rate≤0.01%.

Product details

1.Technical Architecture and Innovation

Pneumatic execution system:

Multi-stage throttle valve:Festo pneumatic valve set is used to achieve pressure gradient control.

Flexible connection design:silicone corrugated pipe sealed,vibration resistance≥10g.

Intelligent control logic:

PID closed-loop algorithm:combined with the temperature compensation module,the ambient temperature fluctuates±10℃and maintains accuracy.

Redundancy protection mechanism:dual sensor cross-verification,single point of failure does not affect the overall function.

2.Process adaptability

Lithography process application:

Wafer alignment:Use stepping table to achieve±0.5μm registration accuracy.

Mask plate positioning:Supports repeat positioning of±0.05μm within 0.5mm stroke range.

Maintain compatibility:

Modular interface:compatible with ASML 4022.428.05412 Kay valve set,supports quick replacement.

Diagnostic interface:output status data through the VME bus,adapted to the ASML RadiSys control system.

Technical specifications:ASML 4022.428.1134

Parameters Specification Description

Working pressure range 0-10bar

Positioning accuracy±0.1μm(static);±0.3μm(dynamic)

Response time≤10ms(pressure step response)

Ambient temperature-20℃to 60℃

Core Valuesand Performance Highlights

1.High reliability design

Anti-pollution ability:The silicone sealed structure can withstand 0.1μm-level particle pollution,and its life span is≥50 million cycles.

Low maintenance cost:Modular design reduces single repair time to 2 hours.

2.Process compatibility

Multi-process adaptation:supports i-line(365nm)and KrF(248nm)lithography process switching.

Dynamic compensation:The temperature drift compensation algorithm improves long-term stability by 40%.

Respond to challenges and create value

1.High-precision positioning problem

Technical breakthrough:multi-axis synchronization control algorithm+flexible connection design to achieve wafer table jitter<0.01μm.

Application case:After the deployment of a memory factory,the defect density of the critical layer is reduced by 30%.

2.Adaptability of complex environments

Technical breakthrough:wide temperature domain sealing structure+anti-electromagnetic interference design,meeting the environmental requirements of Class 1 in the clean room.

Application case:A logic chip factory operates continuously for 3 years without failure in an environment with a humidity of 40%-60%.