描述

产品简要说明

ASML 4022.428.1276是ASML专为先进制程半导体制造设计的高精度晶圆步进系统,核心特性包括:

亚微米级定位精度:重复定位精度≤0.05μm,支持28nm以下制程晶圆传输。

多规格兼容性:适配300mm及以下晶圆,厚度范围300~800μm,兼容硅、化合物半导体等基材。

高可靠性设计:无故障运行时间(MTBF)≥5000小时,耐受真空环境(<1e-5 mbar)。

产品详细说明

1.技术架构与核心功能

运动控制单元:

基于线性马达与磁悬浮技术,实现X/Y/Z三轴运动,定位速度≤200mm/s,加速度≤10g。

闭环反馈系统集成激光干涉仪(分辨率0.1nm)与压电陶瓷微调模块,动态跟踪误差≤0.1μm。

晶圆承载系统:

真空吸附盘设计,吸附力≥50mbar,支持晶圆边缘检测与自动对齐。

温控模块维持晶圆温度±0.5℃波动,减少热应力导致的形变。

环境适应性设计:

氦气循环冷却系统,有效降低运动部件温漂至≤0.01μm/K。

碳纤维复合材料框架,抗振性能≥100Hz。

2.性能突破

传输效率:

单晶圆处理时间≤3秒(含定位与对齐),产能提升至300片/小时(200mm晶圆)。

良率保障:

晶圆表面划伤率≤0.01%,边缘崩边控制≤5μm。

跨代适配性:

兼容ASML TWINSCAN系列光刻机(如XT:1950i至NXE:3600D),支持多光刻工艺集成。

技术规格:ASML 4022.428.1276

参数项规格描述

定位精度重复定位≤0.05μm,单次定位≤0.1μm

运动范围X/Y轴±250mm,Z轴±50mm

环境耐受性真空耐受<1e-5 mbar,温度范围15~30℃

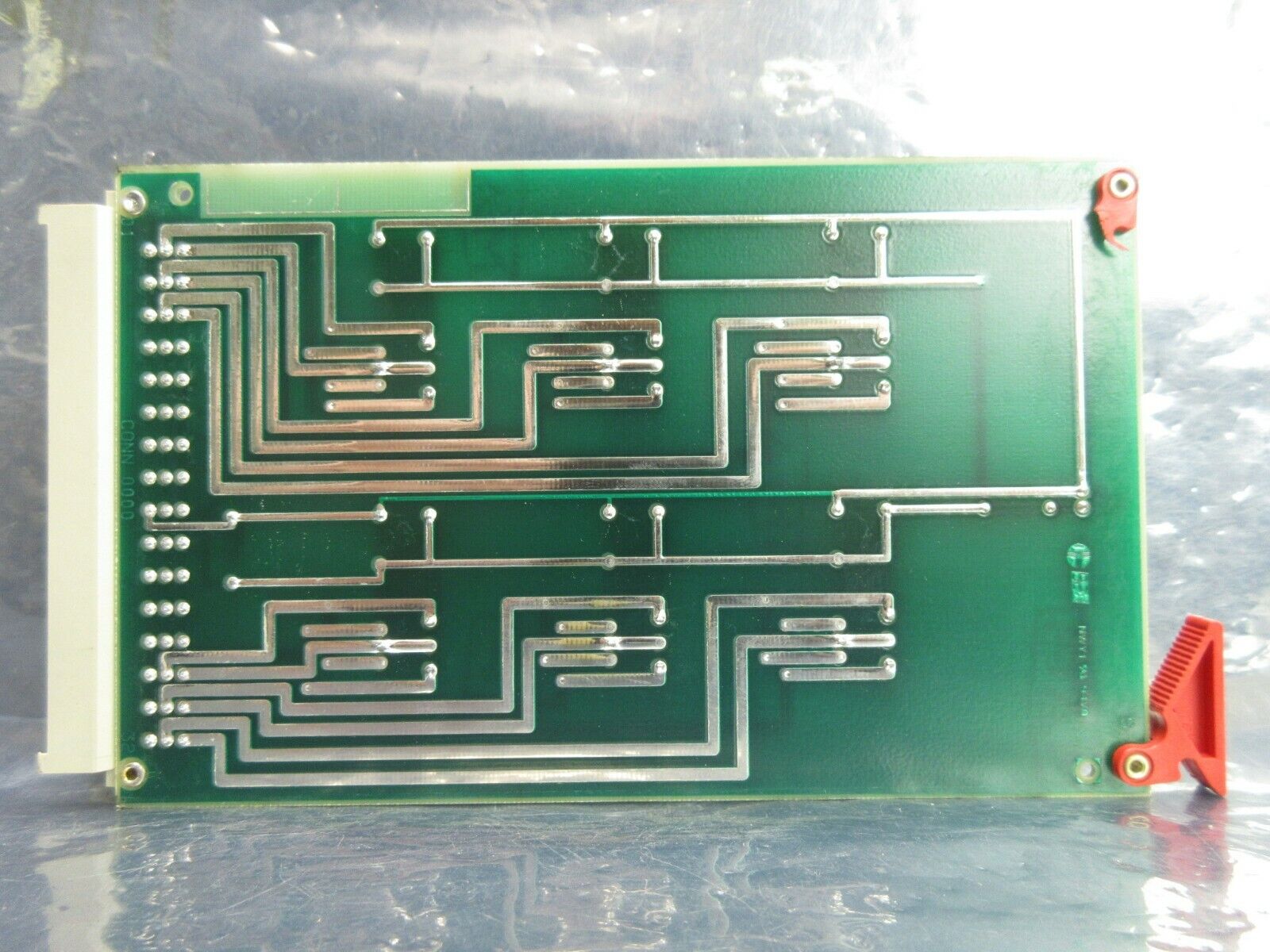

接口类型PCIe Gen4×16(控制接口)+RS-422(设备通信)

功耗≤500W(运行模式)

Product brief description

ASML 4022.428.1276 is a high-precision wafer stepping system designed by ASML for advanced process semiconductor manufacturing.The core features include:

Submicron-level positioning accuracy:Repeated positioning accuracy≤0.05μm,supports process wafer transmission below 28nm.

Multi-spec Compatibility:Suitable for wafers of 300mm or below,with a thickness range of 300~800μm,compatible with substrates such as silicon,compound semiconductors and other substrates.

High reliability design:Fault-free running time(MTBF)≥5000 hours,with vacuum environment(<1e-5 mbar).

Product details

1.Technical architecture and core functions

Motion control unit:

Based on linear motor and magnetic levitation technology,the three-axis movement of X/Y/Z is realized,with a positioning speed of≤200mm/s and an acceleration of≤10g.

The closed-loop feedback system integrates a laser interferometer(resolution 0.1nm)and a piezoelectric ceramic fine-tuning module,with dynamic tracking error≤0.1μm.

Wafer bearing system:

Vacuum adsorption disk design,adsorption force≥50mbar,supports wafer edge detection and automatic alignment.

The temperature control module maintains the wafer temperature fluctuations of±0.5℃to reduce deformation caused by thermal stress.

Environmental adaptability design:

The helium circulation cooling system effectively reduces the temperature drift of moving parts to≤0.01μm/K.

Carbon fiber composite frame,vibration resistance≥100Hz.

2.Performance breakthrough

Transmission efficiency:

The single wafer processing time is≤3 seconds(including positioning and alignment),and the production capacity is increased to 300 pieces per hour(200mm wafer).

Yield guarantee:

The scratch rate of the wafer surface is≤0.01%,and the edge collapse control is≤5μm.

Cross-generation adaptability:

Compatible with ASML TWINSCAN series lithography machines(such as XT:1950i to NXE:3600D),supports multi-lithography process integration.

Technical specifications:ASML 4022.428.1276

Parameters Specification Description

Positioning accuracy Repeated positioning≤0.05μm,single positioning≤0.1μm

Range of motion:X/Y axis±250mm,Z axis±50mm

Environmental tolerance Vacuum tolerance<1e-5 mbar,temperature range 15-30℃

Interface type PCIe Gen4×16(control interface)+RS-422(device communication)

Power consumption≤500W(operating mode)