描述

产品简要说明

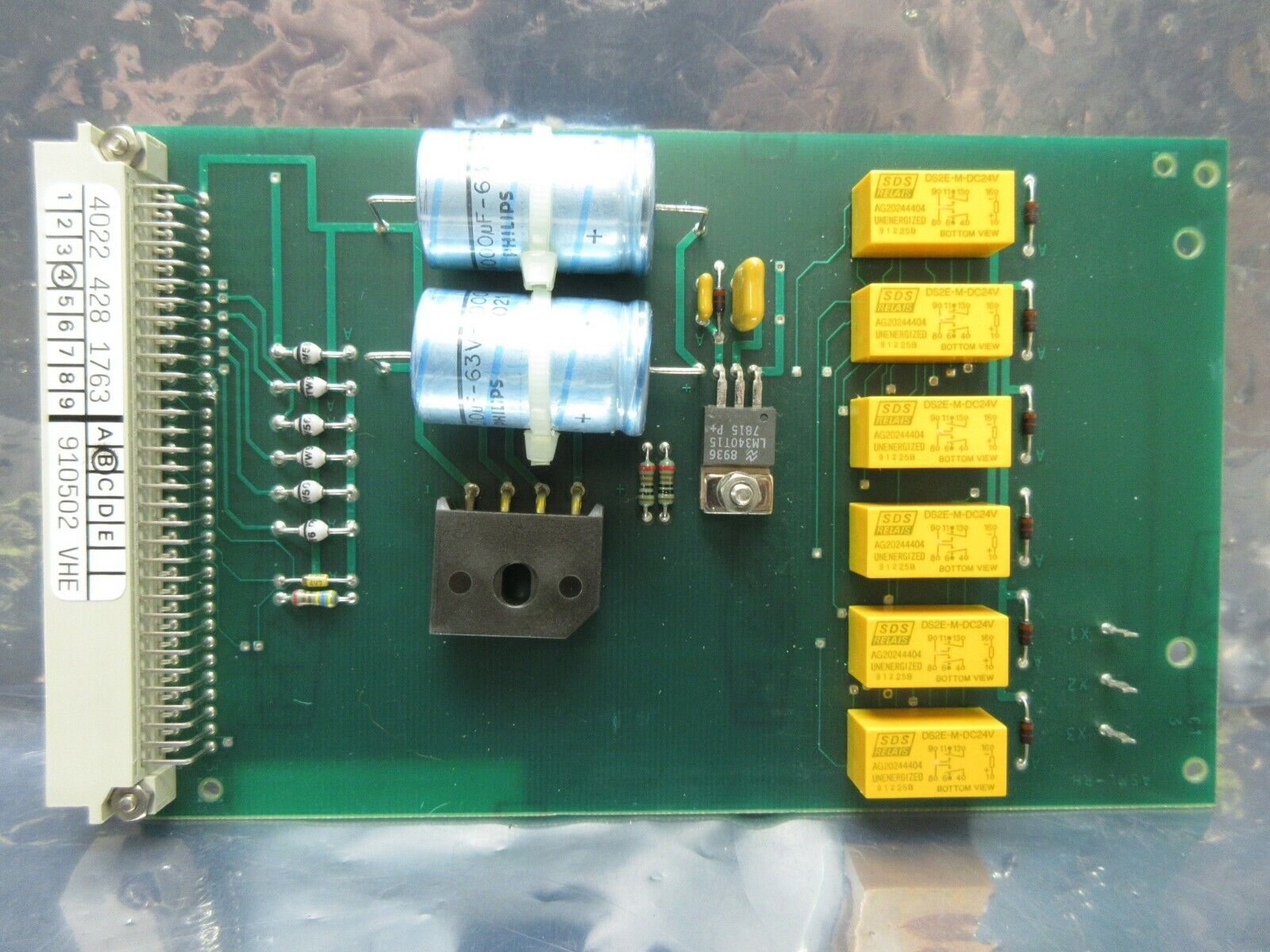

ASML 4022.428.1763是ASML专为工业自动化与精密设备设计的机电式继电器,核心特性包括:

高可靠性:通过ASML严苛的环境测试,MTBF(平均无故障时间)≥100万次循环。

快速响应:触点动作时间≤5ms,适用于高频开关控制场景。

宽范围兼容性:支持AC/DC 220V负载,触点容量可达10A/250V。

产品详细说明

1.技术架构与核心功能

机械结构设计:

采用双金属片与电磁线圈复合驱动,确保触点接触电阻≤50mΩ。

真空封装工艺,防护等级达IP67,耐受粉尘、湿气及腐蚀性环境。

电气特性优化:

触点材料为银氧化镉合金,抗电弧侵蚀能力提升30%,寿命延长至500万次。

线圈功耗≤0.5W(DC 12V模式),支持低功耗工业控制需求。

智能保护机制:

内置过载保护模块,电流超过额定值120%时自动切断电路。

温度传感器实时监测线圈温度,异常时触发报警并进入休眠模式。

2.性能突破

环境适应性:

工作温度范围-40℃~+85℃,振动耐受≥10g(5~500Hz)。

高湿度环境(90%RH)下仍保持绝缘电阻≥100MΩ。

模块化扩展:

支持多触点配置(SPST/DPDT),适配不同电路拓扑需求。

接口兼容工业标准(如M12连接器),便于系统集成。

技术规格:ASML 4022.428.1763

参数项规格描述

触点容量AC 10A/250V,DC 10A/250V

动作时间≤5ms(典型值)

接触电阻≤50mΩ(常闭触点)

环境耐受性工作温度-40℃~+85℃,防护等级IP67

线圈功耗DC 12V模式下≤0.5W

核心价值与性能亮点

1.工业级可靠性

极端环境适应:通过ASML光刻机生产线验证,耐受高洁净度车间的电磁干扰与机械振动。

长寿命设计:银氧化镉触点与低功耗线圈结合,减少维护频率至传统继电器的1/3。

2.智能控制集成

过载保护:实时监测电流与温度,主动切断异常电路,降低设备损坏风险。

低功耗优化:支持休眠模式,在待机状态下能耗≤0.1W,适用于能源敏感场景。

3.行业适配性

半导体制造:用于光刻机晶圆传输系统的电磁阀控制与信号切换。

自动化产线:适配PLC、机器人等设备的开关控制,兼容Modbus与CANopen协议。

应对挑战,创造价值

1.工业环境干扰问题

技术突破:真空封装与电磁屏蔽设计,抗干扰能力提升至IEC 61000-4-2 Level 4。

应用案例:某汽车电子产线部署后,继电器误动作率从0.5%降至0.02%。

2.高频率开关需求

技术突破:双金属片驱动与低惯性结构,动作速度提升至传统继电器的2倍。

应用案例:某光伏逆变器项目中,继电器寿命延长至300万次循环。

Product brief description

ASML 4022.428.1763 is an electromechanical relay designed by ASML for industrial automation and precision equipment.The core features include:

High reliability:Passed ASML rigorous environmental testing,MTBF(average failure-free time)≥1 million cycles.

Quick response:The contact action time is≤5ms,suitable for high-frequency switch control scenarios.

Wide range compatibility:Supports AC/DC 220V load,contact capacity up to 10A/250V.

Product details

1.Technical architecture and core functions

Mechanical structure design:

The bimetal plate and the electromagnetic coil are combined to ensure that the contact contact resistance is≤50mΩ.

Vacuum packaging process,protection level up to IP67,and withstand dust,moisture and corrosive environments.

Electrical characteristics optimization:

The contact material is silver cadmium oxide alloy,with an arc corrosion resistance of 30%,and a life span extending to 5 million times.

The coil power consumption is≤0.5W(DC 12V mode),supporting low-power industrial control needs.

Intelligent protection mechanism:

Built-in overload protection module,automatically cut off the circuit when the current exceeds the rated value of 120%.

The temperature sensor monitors the coil temperature in real time,triggers an alarm when abnormal and enters sleep mode.

2.Performance breakthrough

Environmental adaptability:

The working temperature range is-40℃~+85℃,and the vibration resistance is≥10g(5~500Hz).

The insulation resistance is still maintained at a high humidity environment(90%RH).

Modular extension:

Supports multi-contact configuration(SPST/DPDT)to adapt to different circuit topology requirements.

The interface is compatible with industry standards(such as M12 connectors)for easy system integration.

Technical specifications:ASML 4022.428.1763

Parameters Specification Description

Contact capacity AC 10A/250V,DC 10A/250V

Action time≤5ms(typical)

Contact resistance≤50mΩ(normally closed contact)

Environmental tolerance Operating temperature-40℃~+85℃,protection level IP67

Coil power consumption DC≤0.5W in 12V mode

Core Valuesand Performance Highlights

1.Industrial-grade reliability

Extreme environmental adaptation:Verified by the ASML lithography machine production line,it withstands electromagnetic interference and mechanical vibrations in high-cleanness workshops.

Long-life design:Silver cadmium oxide contacts are combined with low-power coils to reduce maintenance frequency to 1/3 of traditional relays.

2.Intelligent control integration

Overload protection:Monitor current and temperature in real time,actively cut off abnormal circuits,and reduce the risk of equipment damage.

Low power consumption optimization:supports sleep mode,energy consumption≤0.1W in standby state,suitable for energy-sensitive scenarios.

3.Industry adaptability

Semiconductor manufacturing:Solenoid valve control and signal switching for lithography wafer transmission system.

Automated production line:adapted to switch control of PLC,robot and other equipment,compatible with Modbus and CANopen protocols.

Respond to challenges and create value

1.Industrial environmental interference issues

Technical breakthrough:vacuum packaging and electromagnetic shielding design,anti-interference capability has been improved to IEC 61000-4-2 Level 4.

Application case:After the deployment of a certain automotive electronics production line,the relay malfunction rate dropped from 0.5%to 0.02%.

2.High frequency switch requirements

Technical breakthrough:Bimetallic plate drive and low inertia structure,the operating speed is increased to twice that of traditional relays.

Application case:In a photovoltaic inverter project,the relay life is extended to 3 million cycles.