描述

产品简要说明

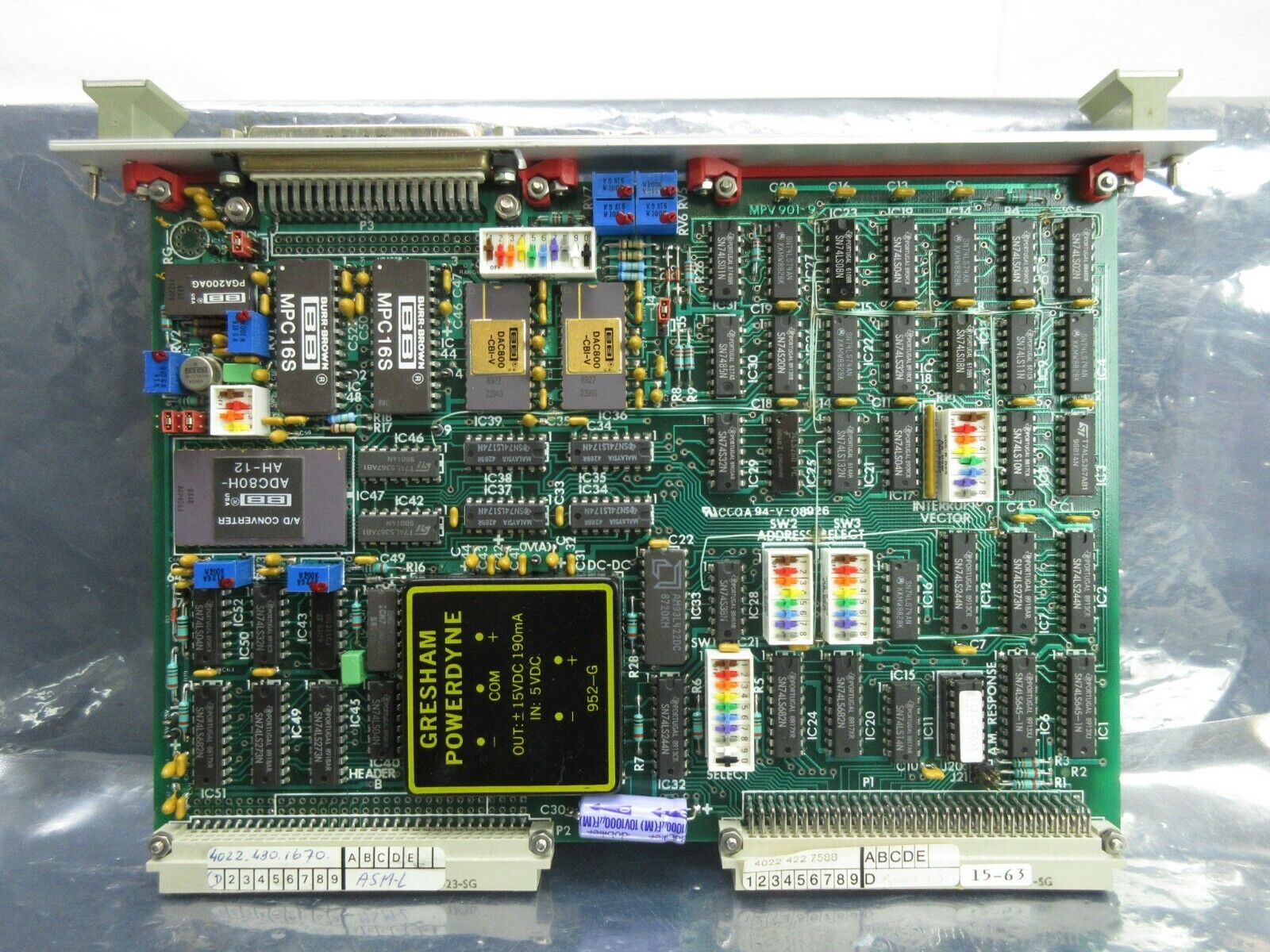

ASML 4022.430.1670是一款专为极紫外(EUV)光刻机设计的光学反射镜组件,核心功能包括:

纳米级光路控制:反射镜面形误差≤0.5nm(PV),波前误差≤0.03λ(λ=13.5nm)。

抗污染设计:表面镀有Mo/Si多层膜,反射率≥70%,耐受真空环境(<10⁻⁶mbar)。

动态热管理:集成液冷循环系统,温控精度±0.01℃,抑制热漂移导致的波前畸变。

产品详细说明

1.技术架构与创新

多层镀膜工艺:

Mo/Si反射膜:采用原子层沉积(ALD)技术,膜层厚度均匀性≤0.5%,反射率波动<2%。

抗污染涂层:表面疏水处理(接触角>150°),减少EUV光源产生的碳沉积。

结构设计:

轻量化框架:钛合金基底+碳纤维复合材料支撑,质量≤5kg,热膨胀系数(CTE)<1.2×10⁻⁶/℃。

磁悬浮定位:配合压电驱动器实现±40μm行程微调,重复定位精度≤0.8nm。

2.核心功能模块

动态校准系统:

自适应补偿:基于激光干涉仪(波长633nm)的实时波前反馈,校正误差<0.02λ。

振动隔离:主动阻尼系统抑制20Hz-1kHz频段振动,传递率<0.1%。

环境适应性:

真空兼容性:通过ISO 14644-1 Class 1洁净室认证,微粒排放≤0.1个/m³(0.1μm)。

辐射耐受性:可承受EUV光源峰值功率密度≥100W/cm²,无膜层退化。

3.行业应用适配性

EUV光刻机集成:

光学列阵控制:作为ASML TWINSCAN NXE:3600D光刻机的ZEPHYR反射镜组核心组件,支持3nm制程。

多光束叠加:实现4束EUV光的精准相位对准,曝光场均匀性≥99.9%。

量子光学实验:

超导量子比特操控:在4.2K超低温下维持反射率稳定性(波动<0.5%)。

高功率激光实验:耐受10⁶W/cm²激光辐照,无热损伤。

Product brief description

ASML 4022.430.1670 is an optical mirror assembly designed for extreme ultraviolet(EUV)lithography machines,with core functions including:

Nano-scale optical path control:the reflective mirror shape error is≤0.5nm(PV),and the wavefront error is≤0.03λ(λ=13.5nm).

Anti-pollution design:The surface is coated with Mo/Si multi-layer film,reflectivity≥70%,and withstand vacuum environment(<10⁻⁶mbar).

Dynamic thermal management:integrated liquid-cooled circulation system,temperature control accuracy±0.01℃,inhibiting wavefront distortion caused by thermal drift.

Product details

1.Technical Architecture and Innovation

Multi-layer coating process:

Mo/Si reflective film:Atomic layer deposition(ALD)technology is used,the film thickness uniformity is≤0.5%,and the reflectivity fluctuates<2%.

Anti-pollution coating:Surface hydrophobic treatment(contact angle>150°),reducing carbon deposition generated by EUV light sources.

Structural design:

Lightweight frame:titanium alloy substrate+carbon fiber composite support,mass≤5kg,coefficient of thermal expansion(CTE)<1.2×10⁻⁶/℃.

Magnetic levitation positioning:Used with piezoelectric driver to achieve fine adjustment of±40μm stroke,and the repeat positioning accuracy is≤0.8nm.

2.Core functional modules

Dynamic calibration system:

Adaptive compensation:Based on real-time wavefront feedback from laser interferometer(wavelength 633nm),correction error is<0.02λ.

Vibration isolation:The active damping system suppresses vibration in the 20Hz-1kHz frequency band,with a transmission rate of<0.1%.

Environmental adaptability:

Vacuum compatibility:Passed ISO 14644-1 Class 1 Clean Room Certification,Particle Emission≤0.1 units/m³(0.1μm).

Radiation tolerance:It can withstand the peak power density of EUV light source≥100W/cm²,without film degradation.

3.Industry application adaptability

EUV lithography machine integration:

Optical array control:As the core component of the ZEPHYR mirror group of ASML TWINSCAN NXE:3600D lithography machine,it supports 3nm process.

Multi-beam superposition:achieve accurate phase alignment of 4 EUV lights,with exposure field uniformity≥99.9%.

Quantum Optical Experiment:

Superconducting qubit manipulation:Maintain reflectivity stability(volatility<0.5%)at 4.2K ultra-low temperature.

High power laser experiment:tolerate 10⁶W/cm²laser radiation without thermal damage.