描述

产品简要说明

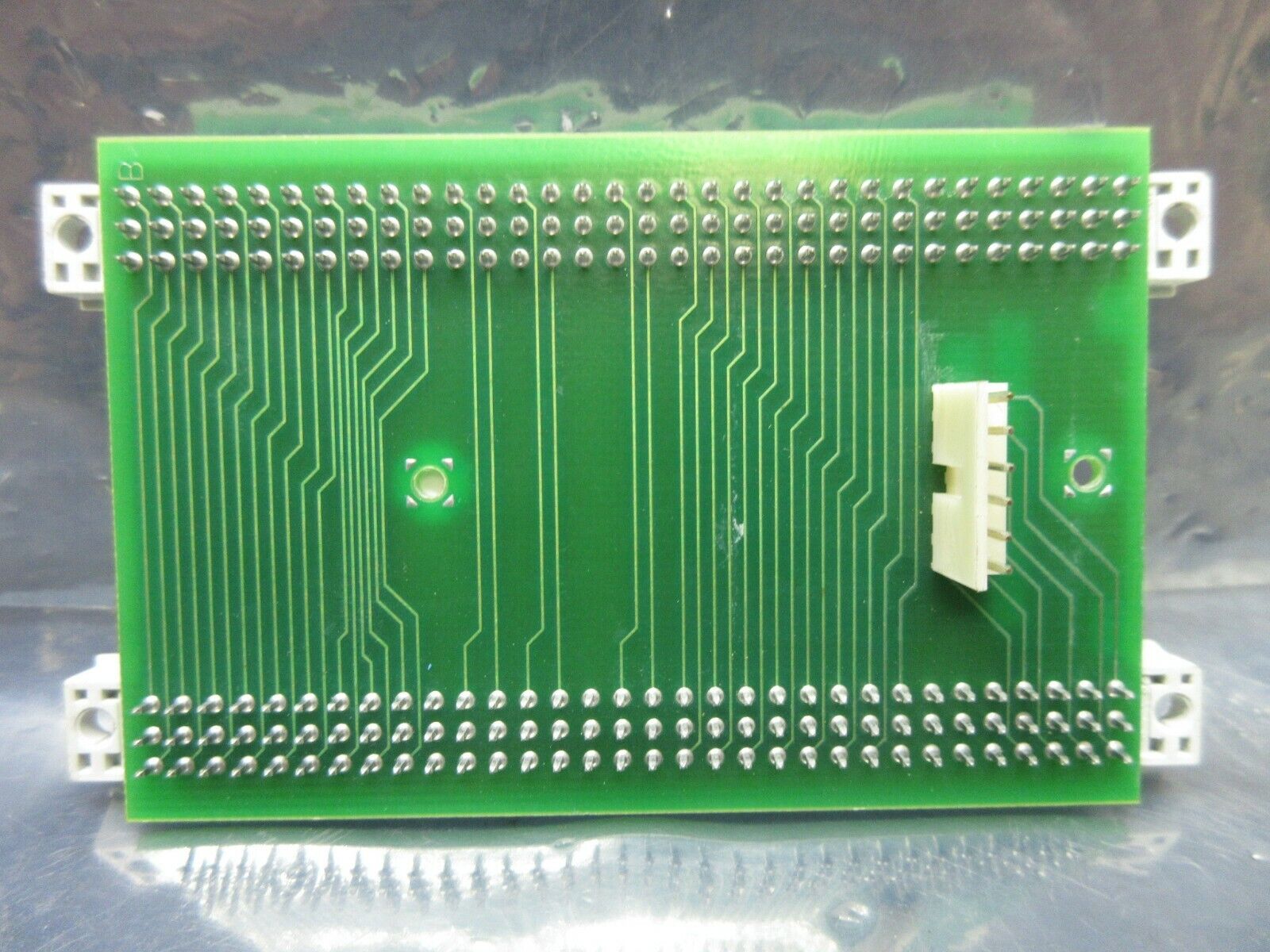

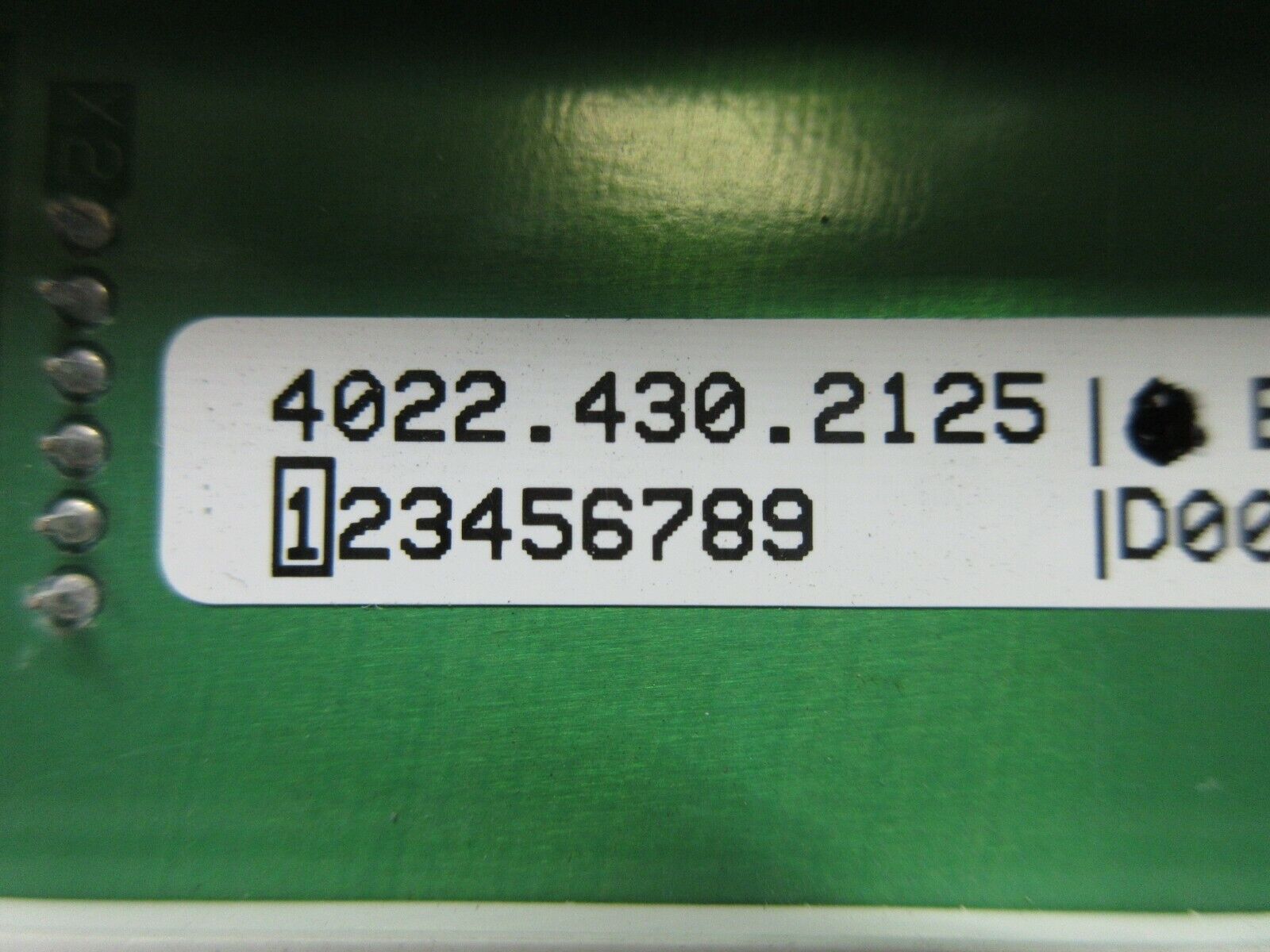

ASML 4022.430.2125是ASML专为工业控制与精密仪器设计的高密度背板PCB,核心特性包括:

多层互联架构:支持16层以上高密度互连(HDI),信号传输速率≥10Gbps。

极端环境适应性:耐受-40℃~+125℃温度范围,抗振动≥10g(5-500Hz)。

模块化设计:兼容PCIe、SATA、FPGA等多种接口协议,支持快速扩展。

产品详细说明

1.技术架构与核心功能

材料与工艺:

基材选择:采用聚酰亚胺(PI)或Rogers高频材料,介电常数(Dk)≤3.5,损耗因子(Df)≤0.0025。

微孔技术:激光钻孔直径≤60μm,孔壁粗糙度≤1μm,实现高密度布线。

信号完整性优化:

集成差分对设计,串扰抑制比(CIR)≥30dB,眼图余量≥20%。

电源层去耦电容密度≥200个/cm²,电压波动≤±1%。

散热与可靠性:

嵌入式铜管散热结构,热阻≤0.5℃/W。

通过MIL-STD-883H标准测试,湿热循环(85℃/85%RH)≥2000小时无失效。

2.性能突破

高频稳定性:

5GHz信号插入损耗≤2dB,相位误差≤5°。

抗电磁干扰:

辐射抗扰度(RS)≥10V/m(10kHz-1GHz),传导抗扰度(CS)≥4kV(1kHz-80MHz)。

长寿命设计:

焊接热循环(-40℃~+260℃)≥500次,金手指磨损率≤0.1μm/次。

技术规格:ASML 4022.430.2125

参数项规格描述

层数16层(可定制至32层)

基材类型Rogers RO4350B/PI复合材料

尺寸范围100mm×150mm~600mm×800mm(定制化生产)

工作温度-40℃~+125℃

核心价值与性能亮点

1.工业级可靠性

极端环境适应性:支持沙漠、极地等恶劣工况,通过盐雾测试(24小时,5%NaCl溶液)无腐蚀。

故障自诊断:集成BIST(内建自测试)电路,可实时监测信号完整性与电源稳定性。

2.高密度互联优势

空间节省:相比传统背板,体积减少40%,重量降低30%。

协议兼容性:支持PCIe 5.0、SATA 6Gbps、LVDS等接口,单板可集成≥128个连接器。

3.生态协同设计

ASML设备适配:专为ASML光刻机(如PAS 2500/5000系列)的运动控制、传感器模块设计,兼容其通信协议(XICB接口)。

跨行业扩展:可适配医疗影像设备(如CT机探测器)、航空航天导航系统等高可靠性场景。

Product brief description

ASML 4022.430.2125 is a high-density backplane PCB designed by ASML for industrial control and precision instruments.The core features include:

Multi-layer interconnection architecture:supports high-density interconnection(HDI)above 16 layers,and the signal transmission rate is≥10Gbps.

Extreme environmental adaptability:Tolerate temperature range of-40℃~+125℃,vibration resistance≥10g(5-500Hz).

Modular design:compatible with PCIe,SATA,FPGA and other interface protocols,and supports rapid expansion.

Product details

1.Technical architecture and core functions

Materials and Process:

Substrate selection:Use polyimide(PI)or Rogers high-frequency materials,with dielectric constant(Dk)≤3.5,and loss factor(Df)≤0.0025.

Micropore technology:laser drilling diameter is≤60μm,hole wall roughness is≤1μm,achieving high-density wiring.

Signal integrity optimization:

Integrated differential pair design,crosstalk suppression ratio(CIR)≥30dB,eye image margin≥20%.

The power layer decoupling capacitor density is≥200 pieces/cm²,and the voltage fluctuates≤±1%.

Heat dissipation and reliability:

Thermal resistance of embedded copper tube is≤0.5℃/W.

Passed the MIL-STD-883H standard test,there was no failure in humidity and heat cycle(85℃/85%RH)for≥2000 hours.

2.Performance breakthrough

High frequency stability:

The 5GHz signal insertion loss is≤2dB,and the phase error is≤5°.

Anti-electromagnetic interference:

Radiation immunity(RS)≥10V/m(10kHz-1GHz),conduction immunity(CS)≥4kV(1kHz-80MHz).

Long life design:

The welding thermal cycle(-40℃~+260℃)is≥500 times,and the wear rate of gold fingers is≤0.1μm/time.

Technical specifications:ASML 4022.430.2125

Parameters Specification Description

Number of layers:16 layers(customized to 32 layers)

Substrate Type Rogers RO4350B/PI Composite

Size range:100mm×150mm~600mm×800mm(customized production)

Working temperature-40℃~+125℃

Core Valuesand Performance Highlights

1.Industrial-grade reliability

Extreme environmental adaptability:Supports harsh working conditions such as deserts and polar regions,and passes salt spray test(24 hours,5%NaCl solution)without corrosion.

Fault self-diagnosis:Integrated BIST(built-in self-test)circuit,which can monitor signal integrity and power stability in real time.

2.Advantages of high-density interconnection

Space saving:Compared with traditional back panels,the volume is reduced by 40%and the weight is reduced by 30%.

Protocol compatibility:supports PCIe 5.0,SATA 6Gbps,LVDS and other interfaces,and the single board can integrate≥128 connectors.

3.Ecological collaborative design

ASML device adaptation:designed for motion control and sensor modules of ASML lithography machines(such as PAS 2500/5000 series),and compatible with its communication protocol(XICB interface).

Cross-industry expansion:It can be adapted to high-reliability scenarios such as medical imaging equipment(such as CT machine detectors),aerospace navigation systems,etc.