描述

产品简要说明

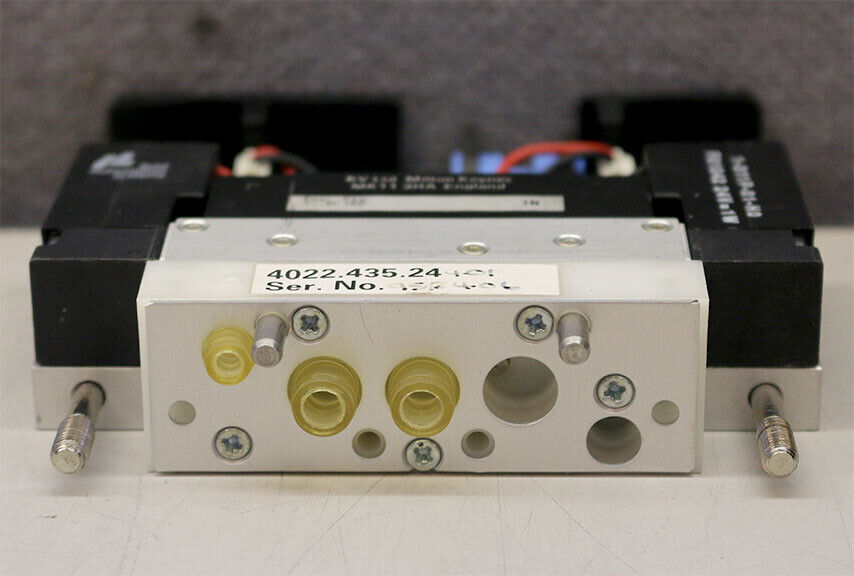

ASML 4022.435.24401是ASML为新一代EUV光刻机设计的相位控制模块,核心特性包括:

超精密波前校准:相位误差补偿精度≤0.02λ(RMS),支持自适应算法动态调整。

多物理场协同控制:集成热漂移补偿、电磁屏蔽(EMI≥80dB)与振动抑制(频段1-1kHz)。

高稳定性输出:光束偏振度≥99.5%,功率波动≤0.1%(RMS)。

产品详细说明

1.技术架构与核心功能

相位校准系统:

波前传感器:基于Shearing Interferometer的实时检测,采样频率≥2kHz。

变形镜驱动:压电陶瓷(PZT)阵列控制,单轴位移精度≤0.005nm。

多物理场耦合模块:

热管理:闭环液氮冷却系统,透镜温度波动≤0.003℃。

电磁兼容:多层屏蔽结构,射频干扰(RFI)抑制比≥25dB。

智能反馈算法:

基于神经网络的相位预测模型,补偿响应时间≤5ms。

多目标优化控制,平衡相位校正速度与能量损耗(效率≥98%)。

2.性能突破

极端环境适应性:

真空环境(<1e-8 mbar)下光束传输损耗≤0.02%/米。

超低温(-200℃)下材料热膨胀系数(CTE)≤0.03ppm/℃。

抗干扰能力:

机械振动抑制效率≥97%(频段10-500Hz)。

长寿命设计:

变形镜疲劳寿命≥2e9次循环,冷却系统可靠性≥99.99%。

技术规格:ASML 4022.435.24401

参数项规格描述

相位误差补偿RMS≤0.02λ( 13.5nm波长)

光束偏振度≥99.5%(线偏振)

热稳定性温控精度≤0.003℃,热漂移补偿效率≥97%

振动抑制频段10-500Hz,隔振效率≥97%

核心价值与性能亮点

1.先进制程适配

2nm以下制程支持:通过动态相位校正,单次曝光分辨率≤2nm(half-pitch)。

极紫外光束整形:支持多光束干涉技术,曝光均匀性误差≤0.3%。

2.工业级可靠性

故障预警系统:基于振动频谱分析的机械部件寿命预测,预警准确率≥95%。

冗余设计:双波前传感器实时校验,数据同步误差≤0.1λ。

3.生态协同创新

ASML NXE 3600D适配:兼容其新型光学控制协议(OCP 5.0)。

未来升级预留:支持数值孔径(NA)≥0.6的扩展接口。

Product brief description

ASML 4022.435.24401 is a phase control module designed by ASML for the new generation of EUV lithography machines.The core features include:

Ultra-precision wavefront calibration:phase error compensation accuracy≤0.02λ(RMS),supports dynamic adjustment of adaptive algorithms.

Multi-physics coordinated control:integrated thermal drift compensation,electromagnetic shielding(EMI≥80dB)and vibration suppression(frequency band 1-1kHz).

High stability output:beam polarization≥99.5%,power fluctuation≤0.1%(RMS).

Product details

1.Technical architecture and core functions

Phase calibration system:

Wavefront sensor:Real-time detection based on Shearing Interferometer,sampling frequency≥2kHz.

Deformation mirror drive:piezoelectric ceramic(PZT)array control,uniaxial displacement accuracy≤0.005nm.

Multi-physics coupling module:

Thermal management:closed-loop liquid nitrogen cooling system,lens temperature fluctuation≤0.003℃.

Electromagnetic compatibility:multi-layer shielding structure,radio frequency interference(RFI)suppression ratio≥25dB.

Intelligent feedback algorithm:

Based on the phase prediction model of neural network,the compensation response time is≤5ms.

Multi-objective optimization control,balancing phase correction speed and energy loss(efficiency≥98%).

2.Performance breakthrough

Extreme environmental adaptability:

The beam transmission loss under vacuum environment(<1e-8 mbar)is≤0.02%/meter.

The thermal expansion coefficient(CTE)of the material at ultra-low temperature(-200℃)is≤0.03ppm/℃.

Anti-interference ability:

Mechanical vibration suppression efficiency is≥97%(frequency band 10-500Hz).

Long life design:

The fatigue life of the deforming mirror is≥2e9 cycles,and the reliability of the cooling system is≥99.99%.

Technical specifications:ASML 4022.435.24401

Parameters Specification Description

Phase error compensation RMS≤0.02λ( 13.5nm wavelength)

Beam polarization≥99.5%(linear polarization)

Thermal stability Temperature control accuracy≤0.003℃,thermal drift compensation efficiency≥97%

Vibration suppression frequency band 10-500Hz,vibration isolation efficiency≥97%

Core Valuesand Performance Highlights

1.Advanced process adaptation

The following 2nm process supports:through dynamic phase correction,the single exposure resolution is≤2nm(half-pitch).

Extreme ultraviolet beam shaping:supports multi-beam interference technology,with an exposure uniformity error of≤0.3%.

2.Industrial-grade reliability

Fault warning system:Mechanical component life prediction based on vibration spectrum analysis,with warning accuracy≥95%.

Redundant design:real-time verification of dual wavefront sensors,data synchronization error≤0.1λ.

3.Ecological collaborative innovation

ASML NXE 3600D adaptation:compatible with its new optical control protocol(OCP 5.0).

Future upgrade reservation:Supports extended interfaces with numerical aperture(NA)≥0.6.