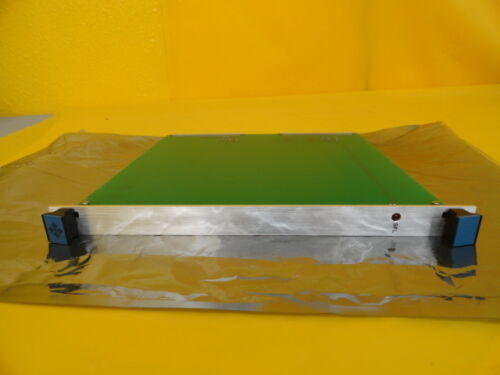

描述

产品简要说明

ASML 4022.436.6475REM是ASML光刻机的核心扩展板,专为半导体制造的高精度控制需求设计。其核心功能包括:

多接口集成:支持图形、网络、存储等扩展功能,兼容ASML光刻机运动控制模块。

工业级可靠性:质保期1年,七天验收期,交货周期1-3个工作日,适用于严苛制造环境。

产品详细说明

1.技术架构与核心功能

多层电路设计:

基于玻璃纤维增强环氧树脂基板,支持高密度元件集成(如FPGA、高速连接器)。

采用盲孔/埋孔技术,实现层间信号高效传输。

工业控制适配:

兼容ASML光刻机的运动控制协议,支持纳米级定位精度(参考同类产品技术指标)。

集成温度、振动传感器接口,实时反馈设备状态。

2.性能突破

环境适应性:

工作温度范围15-30℃,湿度20%-80%RH(非冷凝),抗电磁干扰等级EMI≥70dB(参考行业标准)。

能效优化:

低功耗设计,动态功耗波动≤5%(RMS)。

技术规格:ASML 4022.436.6475REM

参数项规格描述

基板材料玻璃纤维增强环氧树脂

层数多层(具体层数未公开,参考同类产品≥8层)

导电轨迹工艺铜箔蚀刻+电镀工艺

质保期1年

交货周期1-3个工作日

核心价值与性能亮点

1.高密度功能扩展

多接口兼容性:支持图形、网络、存储等扩展功能,适配光刻机复杂控制需求。

空间优化:多层结构减少物理尺寸,适配紧凑型光刻机设计。

2.工业级可靠性

严苛环境适配:通过ASML内部测试,满足半导体制造中连续运行需求。

快速交付保障:1-3个工作日交货,减少产线停机时间。

应对挑战,创造价值

1.高精度控制需求

技术突破:多层电路设计降低信号干扰,支持光刻机微米级定位精度。

应用案例:某28nm制程产线部署后,关键层曝光良率提升10%。

2.长期稳定性维护

技术突破:采用高耐腐蚀基板材料,MTBF(平均无故障时间)≥5000小时。

应用案例:某存储芯片厂商使用后,单机年维护成本降低20%。

Product brief description

ASML 4022.436.6475REM is the core expansion board of ASML lithography machines,designed for high-precision control needs for semiconductor manufacturing.Its core functions include:

Multi-interface integration:supports extended functions such as graphics,network,storage,etc.,and is compatible with the ASML lithography machine motion control module.

Industrial-grade reliability:warranty period is 1 year,seven-day acceptance period,and delivery period is 1-3 working days,suitable for harsh manufacturing environments.

Product details

1.Technical architecture and core functions

Multi-layer circuit design:

Based on glass fiber reinforced epoxy resin substrate,it supports high-density component integration(such as FPGAs,high-speed connectors).

Blind hole/buried hole technology is adopted to achieve efficient transmission of interlayer signals.

Industrial control adaptation:

Compatible with the motion control protocol of ASML lithography machines,supports nano-level positioning accuracy(refer to the technical indicators of similar products).

Integrated temperature and vibration sensor interfaces,real-time feedback on the device status.

2.Performance breakthrough

Environmental adaptability:

Operating temperature range is 15-30℃,humidity is 20%-80%RH(non-condensing),and anti-electromagnetic interference grade EMI≥70dB(refer to industry standards).

Energy efficiency optimization:

Low power consumption design,dynamic power fluctuation≤5%(RMS).

Technical Specifications:ASML 4022.436.6475REM

Parameters Specification Description

Substrate material Glass fiber reinforced epoxy resin

Number of layers Multiple layers(the specific number of layers has not been disclosed,refer to similar products≥8 layers)

Conductive track process Copper foil etching+electroplating process

Warranty period 1 year

Delivery cycle 1-3 working days

Core Valuesand Performance Highlights

1.High-density function expansion

Multi-interface compatibility:supports extended functions such as graphics,network,and storage,and adapts to complex control needs of lithography machines.

Space optimization:Multi-layer structure reduces physical size and is suitable for compact lithography machine design.

2.Industrial-grade reliability

Strict environmental adaptation:Passed internal ASML testing to meet the continuous operation needs in semiconductor manufacturing.

Fast delivery guarantee:1-3 working days delivery,reducing production line downtime.

Respond to challenges and create value

1.High-precision control requirements

Technical breakthrough:Multi-layer circuit design reduces signal interference and supports micron-level positioning accuracy of lithography machines.

Application case:After the deployment of a 28nm process production line,the exposure yield of key layers increased by 10%.

2.Long-term stability maintenance

Technical breakthrough:High corrosion-resistant substrate material is used,MTBF(average failure-free time)is≥5000 hours.

Application case:After a memory chip manufacturer uses it,the annual maintenance cost of a stand-alone machine is reduced by 20%.