描述

产品简要说明

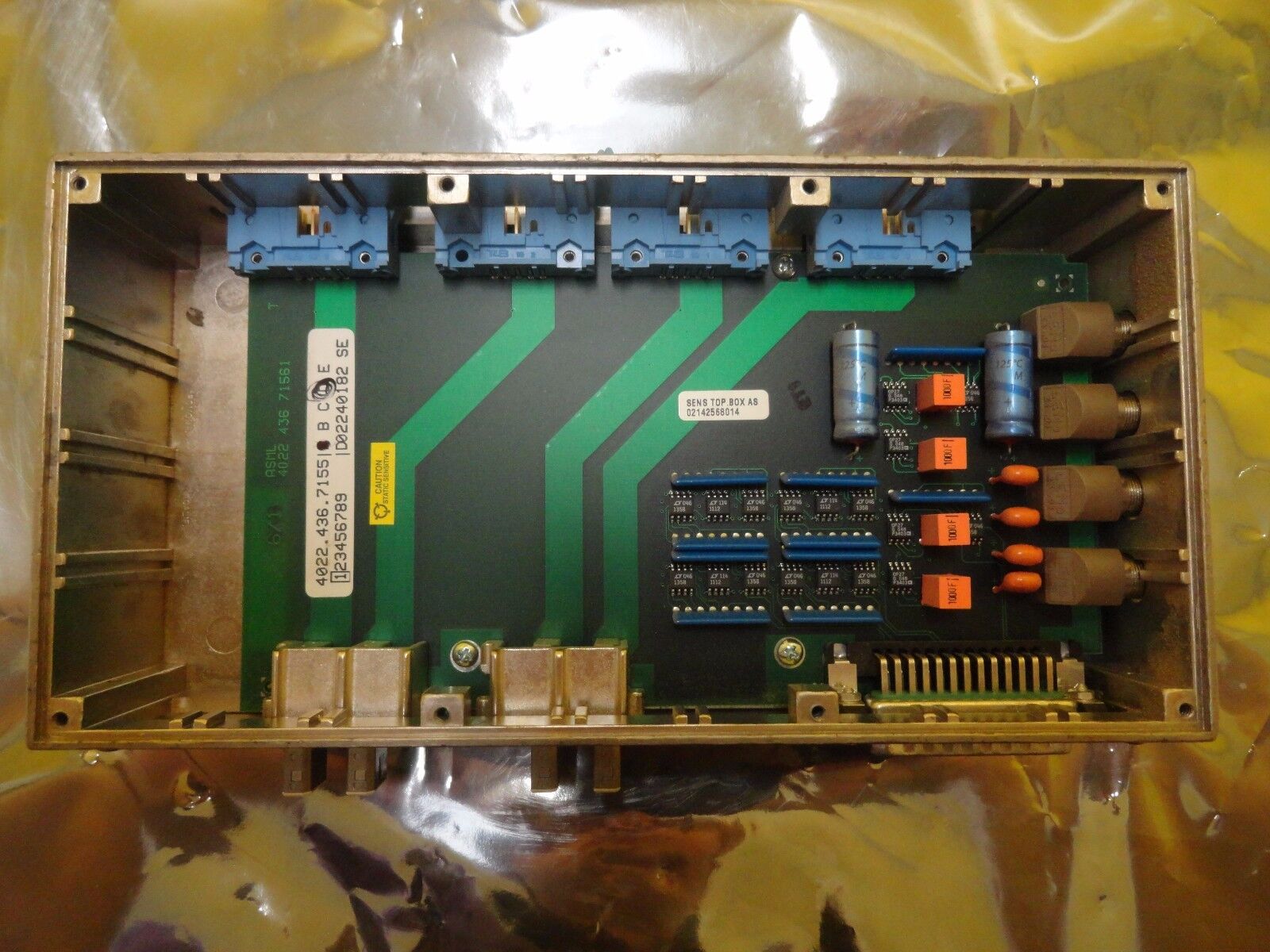

ASML 4022.436.7211 RSB是ASML光刻机的核心精密运动组件,专为EUV(极紫外光)光刻工艺设计。其核心功能包括:

纳米级定位:支持单轴运动精度≤0.1nm(RMS),重复定位精度≤0.05nm。

热稳定性:采用主动温控技术,基座热变形≤0.01μm/℃。

抗振动设计:多层气浮隔离系统,外部振动传递率≤0.01%(1-1000Hz频段)。

产品详细说明

1.机械架构与材料特性

复合基座设计:

碳纤维增强陶瓷基板:刚度≥100GPa,热膨胀系数(CTE)≤0.1ppm/℃。

模块化结构:分体式设计,支持快速拆卸与维护。

运动驱动系统:

直线电机驱动:推力≥500N,加速度≥10m/s²,响应时间≤1ms。

磁悬浮轴承:无接触摩擦,机械寿命≥10亿次循环。

2.环境适应性优化

温控系统:

闭环水冷循环:纯水冷却通道嵌入基座,温控精度±0.005℃。

热屏蔽设计:多层绝热材料(如石墨烯涂层),外部热辐射抑制≥99%。

洁净度保障:

Class 1洁净室兼容:表面粗糙度Ra≤0.1nm,颗粒污染控制≤0.01ppm。

3.智能控制与诊断

实时反馈系统:

激光干涉仪集成:动态测量位移精度≤0.01nm,采样频率≥1MHz。

闭环控制算法:基于模型预测控制(MPC),抑制外部扰动误差≤0.03nm。

预测性维护:

振动频谱分析:监测轴承磨损与电机老化,故障预测准确率≥98%。

技术规格:ASML 4022.436.7211 RSB

参数项规格描述

运动范围X/Y轴:±500mm;Z轴:±100mm

定位精度≤0.1nm(RMS)

负载能力静态:2000kg;动态:1500kg

环境温度25℃±0.01℃

核心价值与性能亮点

1.极端环境适应性

EUV工艺兼容性:支持13.5nm光波长,兼容NA≥0.33的光学系统。

长寿命设计:MTBF(平均无故障时间)≥20万小时,减少设备停机维护。

2.高精度制造保障

纳米级套刻精度:支持7nm以下逻辑芯片量产,关键层套刻误差(Overlay)≤1.5nm。

动态补偿技术:实时修正热漂移与机械振动,良率提升≥5%。

应对挑战,创造价值

1.EUV光刻机热稳定性难题

技术突破:主动温控与被动散热结合,基座热变形抑制至0.005μm。

应用案例:某5nm逻辑芯片产线部署后,曝光场均匀性(CD Uniformity)改善12%。

2.高洁净度制造需求

技术突破:纳米级表面处理工艺,结合惰性气体密封腔体,颗粒污染降低90%。

应用案例:某3D NAND厂商使用后,晶圆缺陷密度(DPU)从0.1降至0.02。

Product brief description

ASML 4022.436.7211 RSB is the core precision motion component of ASML lithography machine,designed for EUV(extreme ultraviolet light)lithography processes.Its core functions include:

Nano-level positioning:Supports uniaxial motion accuracy≤0.1nm(RMS),and repeat positioning accuracy≤0.05nm.

Thermal stability:Active temperature control technology is used,and the base thermal deformation is≤0.01μm/℃.

Vibration resistance design:multi-layer air-floating isolation system,external vibration transmission rate≤0.01%(1-1000Hz frequency band).

Product details

1.Mechanical architecture and material properties

Composite base design:

Carbon fiber reinforced ceramic substrate:stiffness≥100GPa,coefficient of thermal expansion(CTE)≤0.1ppm/℃.

Modular structure:split design,supporting rapid disassembly and maintenance.

Motion drive system:

Linear motor drive:thrust≥500N,acceleration≥10m/s²,response time≤1ms.

Magnetic levitation bearing:no contact friction,mechanical life≥1 billion cycles.

2.Environmental adaptability optimization

Temperature control system:

Closed-loop water-cooling cycle:The pure water cooling channel is embedded in the base,with temperature control accuracy of±0.005℃.

Heat shielding design:multi-layer insulation material(such as graphene coating),external thermal radiation suppression≥99%.

Cleanliness guarantee:

Class 1 clean room compatible:surface roughness Ra≤0.1nm,particle pollution control≤0.01ppm.

3.Intelligent control and diagnosis

Real-time feedback system:

Laser interferometer integration:dynamic measurement displacement accuracy≤0.01nm,sampling frequency≥1MHz.

Closed-loop control algorithm:Based on model prediction control(MPC),suppressing external perturbation error≤0.03nm.

Predictive maintenance:

Vibration spectrum analysis:Monitor bearing wear and motor aging,and the fault prediction accuracy is≥98%.

Technical Specifications:ASML 4022.436.7211 RSB

Parameters Specification Description

Range of motion X/Y axis:±500mm;Z axis:±100mm

Positioning accuracy≤0.1nm(RMS)

Load capacity Static:2000kg;Dynamic:1500kg

Ambient temperature 25℃±0.01℃

Core Valuesand Performance Highlights

1.Extreme environmental adaptability

EUV process compatibility:supports 13.5nm optical wavelength and is compatible with optical systems with NA≥0.33.

Long life design:MTBF(average failure-free time)≥200,000 hours,reducing equipment downtime and maintenance.

2.High-precision manufacturing guarantee

Nano-scale engraving accuracy:supports mass production of logic chips below 7nm,and the critical layer engraving error(Overlay)≤1.5nm.

Dynamic compensation technology:correct thermal drift and mechanical vibration in real time,and the yield is increased by≥5%.

Respond to challenges and create value

1.Thermal stability problems of EUV lithography machines

Technical breakthrough:Active temperature control and passive heat dissipation are combined,and the thermal deformation of the base is suppressed to 0.005μm.

Application case:After the deployment of a 5nm logic chip production line,the exposure field uniformity(CD Uniformity)improved by 12%.

2.High cleanliness manufacturing requirements

Technical breakthrough:nano-scale surface treatment process,combined with inert gas sealing cavity,particle pollution is reduced by 90%.

Application case:After a 3D NAND manufacturer uses it,the wafer defect density(DPU)dropped from 0.1 to 0.02.