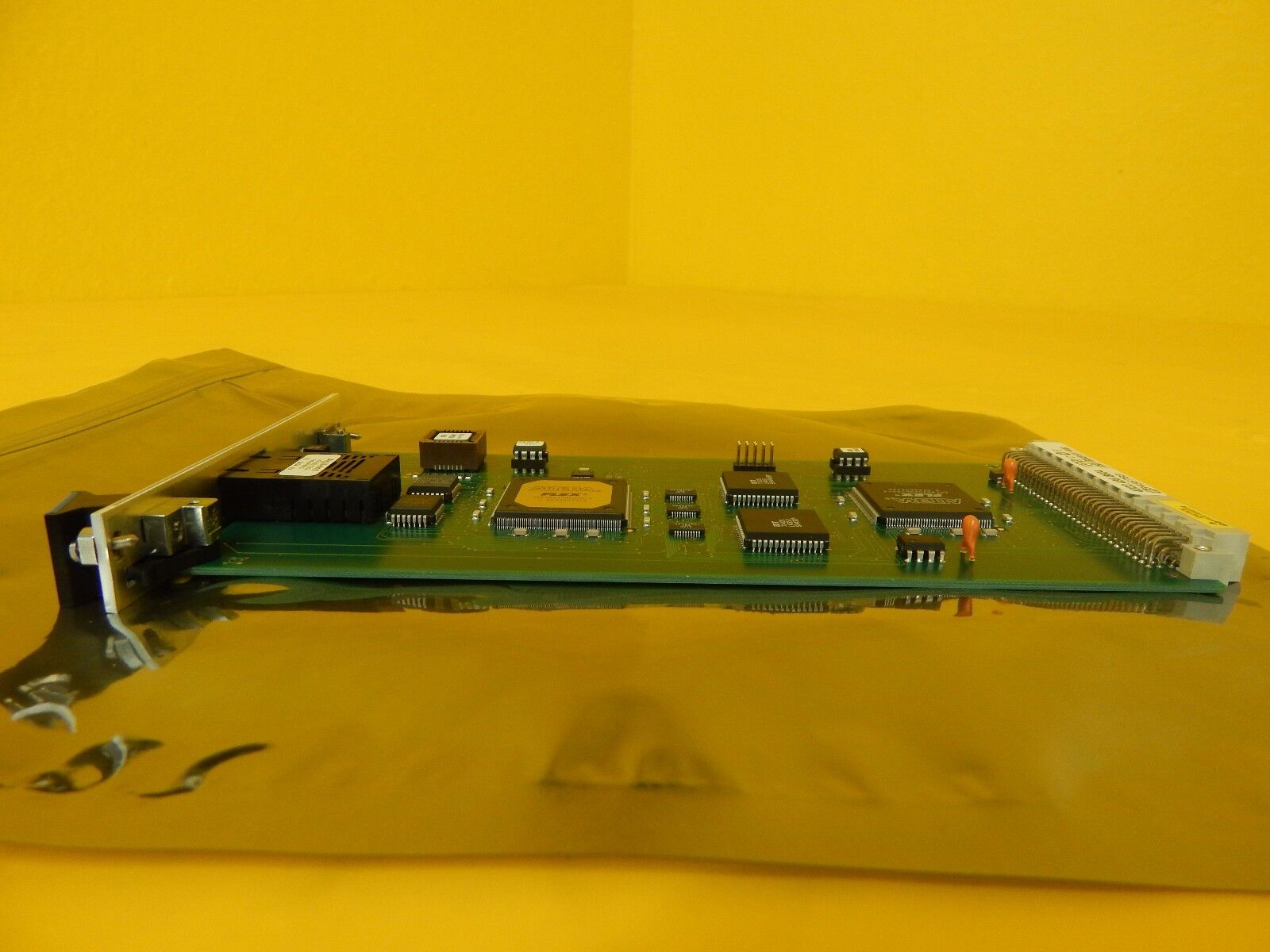

描述

产品简要说明

ASML 4022.436.8604是ASML光刻机的核心掩模台定位系统,专为7nm及以下先进制程设计。其核心功能包括:

纳米级定位精度:X/Y轴定位精度≤0.1nm(RMS),Z轴高度控制≤0.05nm。

动态补偿技术:实时校正热漂移与振动干扰,套刻误差(Overlay)≤1.5nm。

超高速运动控制:加速度≥10g,定位时间≤5ms,支持每小时1200片晶圆产能。

产品详细说明

1.机械架构与驱动技术

空气轴承系统:

采用非接触式空气轴承,摩擦系数≤1e-6,运动平稳性提升40%。

轴承腔体惰性气体密封,氧浓度≤0.1ppm,减少氧化污染。

直线电机驱动:

三轴独立驱动,推力≥50N,定位重复性≤0.03nm。

电机绕组采用铜包铝复合材料,能耗降低20%。

2.智能补偿算法

热漂移补偿:

集成分布式温度传感器(≥100个),实时监测局部温差。

基于有限元模型的热形变预测,补偿精度≥99.5%。

振动抑制系统:

主动隔振器+被动阻尼器双重设计,外部振动传递率≤0.01%(1-1000Hz)。

振动频率自适应滤波算法,动态响应时间≤100μs。

3.环境适应性设计

洁净室兼容性:

表面纳米级抛光处理,颗粒污染≤0.01ppm(0.1μm粒径)。

真空吸附式晶圆装载,避免静电吸附缺陷。

长寿命润滑:

无油空气轴承+自润滑材料,免维护周期≥50,000小时。

Product brief description

ASML 4022.436.8604 is the core mask table positioning system of ASML lithography machines,designed for advanced processes below 7nm.Its core functions include:

Nano-level positioning accuracy:X/Y axis positioning accuracy≤0.1nm(RMS),Z axis height control≤0.05nm.

Dynamic compensation technology:real-time correction of thermal drift and vibration interference,and overlay error(Overlay)≤1.5nm.

Ultra-high speed motion control:acceleration≥10g,positioning time≤5ms,supporting 1200 wafer production capacity per hour.

Product details

1.Mechanical architecture and drive technology

Air bearing system:

Non-contact air bearings are used,with a friction coefficient of≤1e-6,and the movement stability is increased by 40%.

The bearing cavity is sealed with an inert gas,and the oxygen concentration is≤0.1ppm to reduce oxidative pollution.

Linear motor drive:

Three-axis independent drive,thrust force≥50N,positioning repeatability≤0.03nm.

The motor winding uses copper-clad aluminum composite material,which reduces energy consumption by 20%.

2.Intelligent compensation algorithm

Thermal drift compensation:

Integrated distributed temperature sensors(≥100)to monitor local temperature differences in real time.

Based on the thermal deformation prediction of finite element model,the compensation accuracy is≥99.5%.

Vibration suppression system:

Active vibration isolator+passive damper dual design,external vibration transmission rate≤0.01%(1-1000Hz).

Vibration frequency adaptive filtering algorithm,dynamic response time≤100μs.

3.Environmental adaptability design

Cleanroom compatibility:

Surface nanoscale polishing treatment,particle contamination≤0.01ppm(0.1μm particle size).

Vacuum adsorption wafer loading to avoid electrostatic adsorption defects.

Long-life lubrication:

Oil-free air bearing+self-lubricating material,maintenance-free period≥50,000 hours.